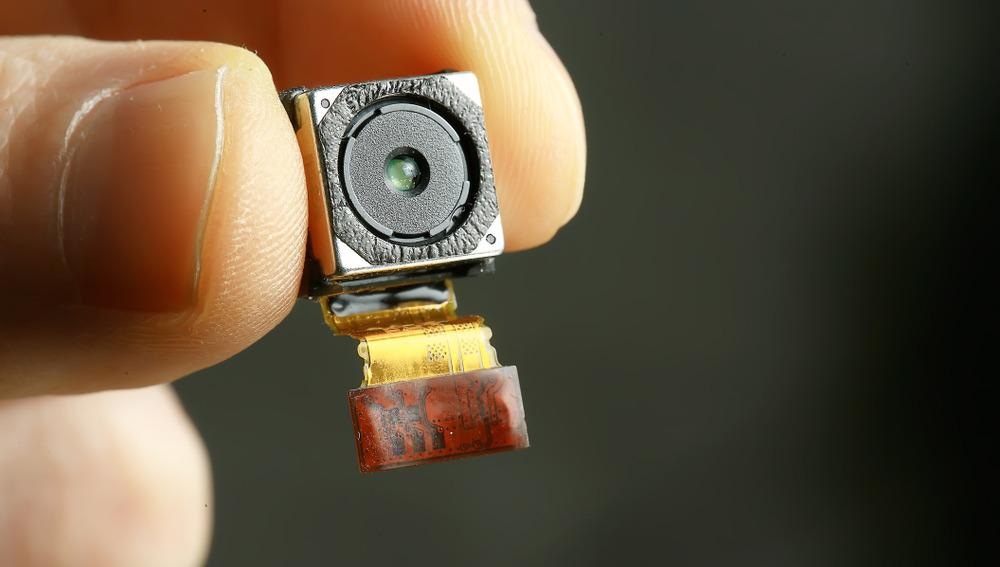

Because of the downsizing of intensity sensors in recent decades, cameras are now widespread across numerous application areas, including medical imaging, cheap cellphones, security, robotics, and autonomous driving. Micro-sized cameras offer a lot of potential for detecting issues in the human body and providing sensing for ultra-small robots, but previous methods generated blurry, distorted pictures with narrow fields of vision.

Image Credit: Kichigin/Shutterstock.com

Researchers from the University of Washington and Princeton University have developed an ultra-compact camera the size of a coarse grain of salt that has surmounted these challenges. The new technique can provide sharp, full-color images that are comparable to those captured by a 500,000-fold bigger compound camera lens. Details of the technology have been published in Nature Communications.

The ultra-compact camera technology might allow minimally invasive endoscopy using medical robots to detect and cure illnesses, as well as enhance imaging for other robots with size and weight limits thanks to a collaborative design of the camera's hardware and computer processing. Thousands of these cameras may be employed to provide full-scene sensing, thereby converting surfaces into cameras.

How Do Micro-Sized Cameras Work?

While a standard camera bends light beams into focus using a series of curved glass or plastic lenses, the new optical system depends on a technology called a metasurface, which can be created similarly to a computer chip. The metasurface is half a millimeter across and studded with 1.6 million cylindrical posts, each about the size of a human immunodeficiency virus (HIV).

Each post has a unique form and functions as an optical antenna. Each post must be designed differently to correctly construct the whole optical field. The interactions of the posts with light, along with machine learning-based algorithms, result in the highest-quality photographs and broadest field of view yet seen in a full-color metasurface camera.

Benefits of Metasurface Optics (Micro-Sized Cameras)

Meta-optics modify incoming light using photonic nano-antennas, providing more design flexibility and a higher space-bandwidth product than typical diffractive optical components (DOEs).

The varied modal features of meta-optical scatterers may offer multifunctional capabilities beyond what standard DOEs can deliver (e.g., frequency, polarization, and angle multiplexing). Deep ultra-violet lithography (DUV) without several etch stages, diamond bending, or monochromatic lithography, as in polymer-based DOEs or traditional optics, may be used to make meta-optics. Researchers have employed meta-optics to produce flat lenses for polarization control, scanning, and holography because of these benefits.

Possible Applications of Micro-Sized Cameras

It is possible to produce metasurfaces made of silicon nitride, a glass-like material that is compatible with normal semiconductor manufacturing procedures used in computer chips. This implies that a particular metasurface design might be mass-produced at a cheaper cost than traditional camera lenses.

Individual surfaces might be made into ultra-high-resolution cameras utilizing ultra-compact imagers, eliminating the need for multiple cameras on your phone in favor of a single massive camera. We may be able to envisage whole new ways to build devices in the future.

Current Challenges of Ultra-Compact Metasurface Lenses

Due to significant wavelength-dependent aberrations generated by interruptions in their imparted phase, current metasurface imaging methods have an order of magnitude higher convergence rate than refractive compound lenses.

Major optical aberrations, narrow fields of vision, and a restricted capacity to record the whole range of visible regions, known as RGB imaging because it blends red, green, and blue to generate distinct colors, have impeded ultra-compact metasurface lenses.

Designing and configuring these tiny microstructures to meet objectives has proven tricky. It Is difficult to generate a big field-of-view RGB picture with this method since there are thousands of these little microstructures and it is unclear how to correctly assemble them.

Recent Studies in Metasurface Optics

Researchers have developed camera designs that use single-optic stacks rather than complex stacks. However, owing to poor diffraction efficiency, these sensors fall short of the capabilities of commodity imagers. Furthermore, owing to their huge rear focal lengths of greater than 10 mm, the most effective systems resist downsizing.

Lensless cameras employ amplitude masks rather than lenses to reduce space, however, this drastically restricts spatial resolution and necessitates extended acquisition durations.

A variety of inverse design methodologies for meta-optics have recently been developed. Existing end-to-end meta-optics optimization approaches cannot scale to large aperture sizes due to memory constraints, and they do not optimize for ultimate full-color image quality, instead of relying on intermediate measurements such as focus spot intensity.

References and Further Reading

Engelberg, J. and Levy, U. (2020) The advantages of metalenses over diffractive lenses. Nature Communications, 11(1), pp. 9–12. https://doi.org/10.1038/s41467-020-15972-9

Peng, Y. et al. (2019) Learned large field-of-view imaging with thin-plate optics. ACM Transactions on Graphics, 38(6). https://doi.org/10.1145/3355089.3356526

Tseng, E. et al. (2021) Neural nano-optics for high-quality thin lens imaging. Nature Communications, 12(1), pp. 1–7. https://doi.org/10.1038/s41467-021-26443-0

Yu, N. and Capasso, F. (2014) Flat optics with designer metasurfaces. Nature Materials, 13(2), pp. 139–150. https://doi.org/10.1038/nmat3839

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.