One of the main barriers to the wider adoption of electric vehicles is battery charging time. So-called extreme fast charging (XFC) technology for replenishing Li-ion batteries in under 15 minutes is a primary focus of researchers and developers.

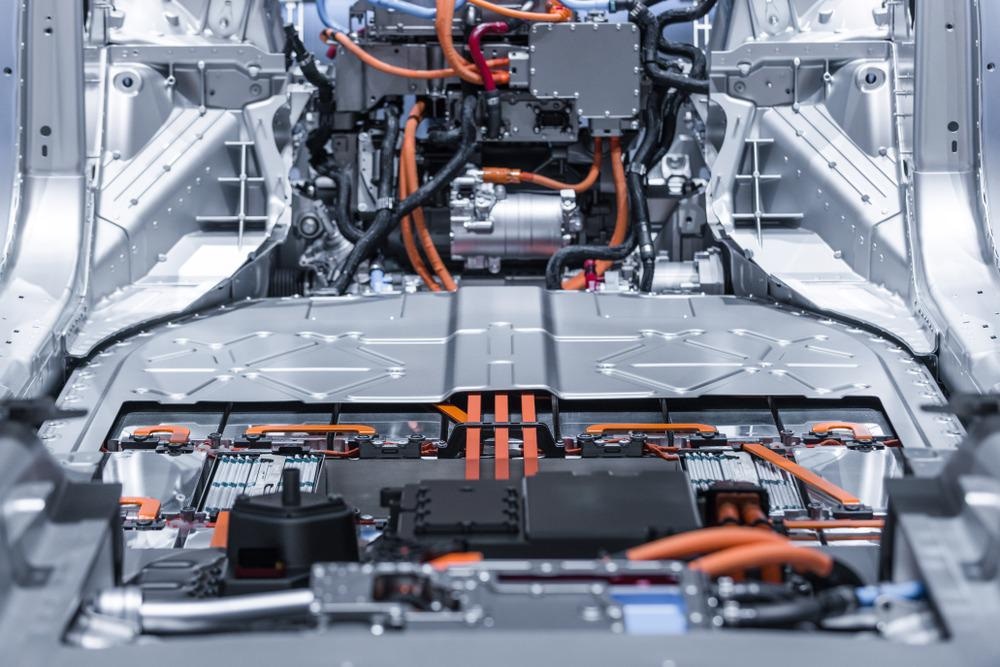

Image Credit: Sergii Chernov/Shutterstock.com

A new study published in ACS Applied Energy Materials in 2021 demonstrates a viable methodology for analyzing Li-ion batteries with high-energy X-ray diffraction (HEXRD). This enabled the researchers to characterize Li-ion cell components in real-time, watching them degrade as a result of the charging process.

Such quantitative and simultaneous analysis of multiple components over time had been a major experimental challenge for battery and charging technology developers. The methods put forward in the new study may lead to major developments in XFC, clearing the road for electric vehicles to a wider consumer market.

Pioneering X-Ray Research at SLAC National Accelerator Laboratory

The research was conducted within the Toney Research Group at the Stanford Synchrotron Lightsource (SSRL), part of the SLAC National Accelerator Laboratory. The group is focused on structural characterization on the materials used for energy conversion and storage, and for information processing.

SLAC is an advanced research facility in California, US, operated by Stanford University and the U.S. Department of Energy. Previously the Stanford Linear Accelerator Center, focus shifted from particle physics to a broader, multi-program laboratory in 2008.

Now, the SLAC National Accelerator Laboratory hosts researchers from a range of disciplines and fields, including chemistry, materials sciences, astrophysics, and X-ray science.

A modestly-sized particle accelerator – only 3 km long, compared to a 27 km long Large Hadron Collider at CERN, Switzerland – is still the California facility’s backbone of operations. Once the site of major particle physics discoveries, the accelerator today works to generate the brightest X-rays in the world for SLAC’s pioneering Linac Coherent Light Source (LCLS) X-ray laser.

Mapping Li-ion Battery Degradation to Unlock Extremely Fast Charging

Wider adoption of electric vehicles will depend, in part, on researchers’ ability to analyze exactly how batteries degrade with time and use. However, the complex, multiscale nature of battery capacity loss mechanisms makes investigating battery degradation particularly challenging.

Previous research has observed that the dominant mechanism contributing to Li-ion battery cell degradation is Li plating, which occurs at XFC rates and is irreversible. But no method had yet been put forward to precisely characterize this mechanism, and so engineering solutions to the problem has not been possible.

Furthermore, properly understanding battery cell degradation requires a combination of global and local analyses. Global analysis can provide valuable diagnostics into the overall degradation of the cell with XFC, but it needs to be complemented with local changes in different components of the battery cell such as Li plating, anode lithiation, and the cathode’s local state-of-charge (SOC).

The method put forward in this research overcomes all these difficulties: characterizing cell degradation and Li plating over time while considering the multi-scale nature of battery degradation and working with the system.

Researchers hope that this will help developers to design new Li-ion battery cells to minimize degradation from XFC. Understanding how irreversible Li plating on the anode leads to cell capacity loss (and its relationship with structural changes in the anode and cathode tracked by their respective SOCs) will be key to designing future generations of Li-ion batteries.

High Energy X-Ray Diffraction: Precise 3D Mapping Over Time

The researchers used an advanced X-ray diffraction (XRD) technique known as HE (for high energy) XRD. Their HEXRD workflow enabled them to obtain a quantitative structural analysis of single-layer pouch cells after XFC cycling in unprecedented detail.

X-ray scattering techniques such as XRD reveal information about materials’ crystal structure, chemical composition, and physical properties. They can be used to analyze surface properties of 3D materials as well as thin films.

In XRD, an X-ray beam hits the sample as a function of incident and scattered angle, polarization, and wavelength (energy). The scattered intensity of the beam is observed and measured.

HEXRD facilitates measurements of materials' 3D microstructure at the mesoscale. The advanced technique has been used for studying various material systems under quasi-static conditions, tracking the evolution of materials’ microstructures over time. HEXRD has enabled us to look at physical mechanisms in situ, where previously we could only deduce their workings from destructive testing and characterization.

In the latest research, the high energy of the X-ray probe ensured the entire Li-ion battery cell would be penetrated. For example, 58 keV of X-ray energy ensured a minimum of 97% transmission through the sample cells. This was essential to combine characterizations of global performance and local phenomena in a multi-scale analysis.

Next Steps for the Research: Batteries and Beyond

While the research shows how Li plating contributes to battery cell degradation, the team expects that the technique laid out in their paper will enable scientists to understand multiscale degradation in energy storage devices beyond Li-ion batteries in the future.

The ability to perform quantitative analysis at local and global scales without breaking up the device makes HEXRD especially well-suited to in situ probing to understand many kinds of degradation mechanisms. Almost any complex material system that undergoes multiscale structural changes can be studied with this new approach.

References and Further Reading

Paul, P.P. et al. (2021) Using In Situ High-Energy X-ray Diffraction to Quantify Electrode Behavior of Li-Ion Batteries from Extreme Fast Charging. ACS Applied Energy Materials. https://doi.org/10.1021/acsaem.1c02348.

Pokharel, R. (2018) Overview of High-Energy X-Ray Diffraction Microscopy (HEDM) for Mesoscale Material Characterization in Three-Dimensions. Materials Discovery and Design. https://doi.org/10.1007/978-3-319-99465-9_7.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.