Image credit: Zapp2Photo/Shutterstock.com

Image credit: Zapp2Photo/Shutterstock.com

Modern robots are employed in many ways and have a wide variety of designs. Many robots use cameras and machine vision to perform intricate tasks and ensure that the robot is doing what it is supposed to. In the future, robotics technology will continue to rely on machine vision systems.

Artificial intelligence is expected to play a massive role in the advancement of machine vision systems moving forward. AI is already facilitating faster, cheaper, and better performing automation in industrial settings. For instance, quality assessment processes, which are usually scheduled at regular intervals, are well-suited for animation.

With AI, machine vision technology can go way beyond human capabilities. For example, AI allows a vision system to perform highly detailed investigations of surfaces in visual, ultraviolet, x-ray, and infrared areas of the electromagnetic spectrum.

AI and other forces driving the evolution and advancement of machine vision technology will unlock many new kinds of applications. Below is a breakdown of vision-enabled trends that are expected to appear soon.

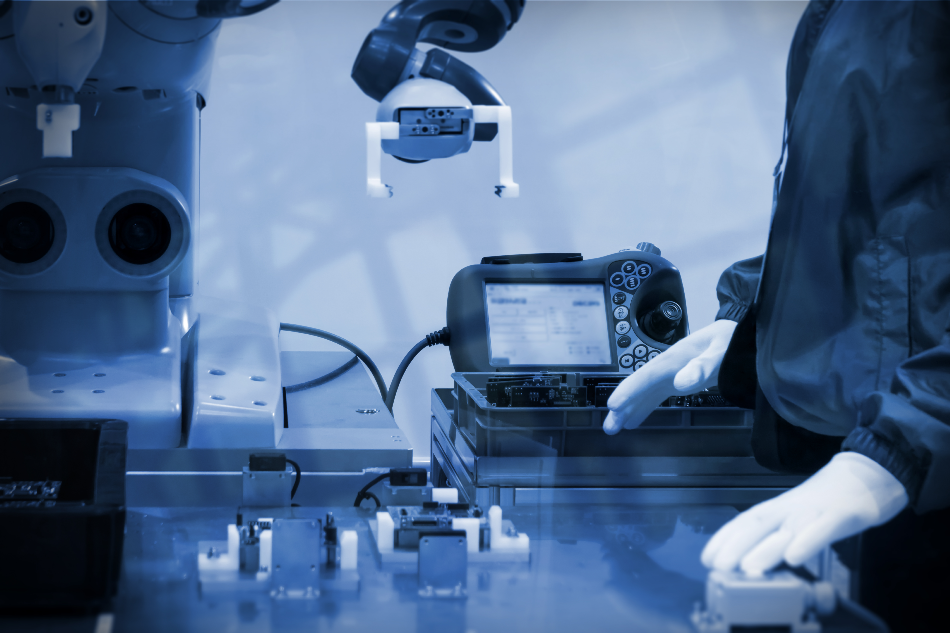

Collaborative Robotics

Collaborative robots, also known as ‘cobots,’ are industrial robots designed to collaborate with people without having to use traditional safety barriers. Cobots do not necessarily replace people. Rather, they can complement people during tedious or complicated tasks. In this arrangement, a robot can handle specific tasks, while a human can intercede to conduct tasks requiring human judgment or manipulation that the robot cannot perform.

Machine vision systems are at the core of how cobots operate efficiently and safely. Modern vision systems enable collaborative robots to recognize the presence of people and avoid unsafe functions and damaging collisions. Machine vision can also help collaborative robots recognize an item's location and orientation in space, possibly so the cobot can grasp it.

As cobots improve and can deal with new applications across a broader array of industries, they will probably be expected to function in more chaotic environments. Therefore, future cobots will have a much more comprehensive sense of the surrounding environment and tasks that must be accomplished in it. They will be able to carry out more complex and less restricted movements to accomplish more tasks.

These robots will not be limited to performing repetitive motions in a highly controlled environment. Instead, cobots of the future will be able to react accordingly to changing conditions to complete the intended task.

Cobot technology’s ultimate goal is pure collaboration with humans. While modern cobots can safely work alongside people, they function independently. In the coming years, cobots could identify human behavior inside the context of a project and modify their behavior accordingly.

3D Vision in Robots

For robots to be more effective partners with humans, they need visual abilities that are more human-like. More specifically, they need to be able to truly see in three dimensions.

The 2D cameras that have been used in machine vision only supply a flat view of the surrounding environment. A 2D machine vision system can perceive the world in terms of x, y, and z axes, but a 3D machine vision system can identify an object in six degrees of freedom, including three kinds of rotation: pitch, yaw, and roll.

There are many benefits of 3D vision technology, including the ability to gather more valuable information, including data on flatness, surface angle, volume, and stability. Machine vision technology in three dimensions can allow for all kinds of new applications, such as more precise and versatile material handling applications.

More Non-Industrial Uses of Robots

There are many non-industrial applications of machine vision in use today, and these areas are expected to be a big part of the technology’s growth.

Autonomous vehicles, drones, municipal systems, surgery, and other areas are all expected to benefit from machine vision technology in the near future. These applications often call for different operational abilities than industrial applications and, therefore, will drive different machine vision innovations.

References and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.