Image Credit: dominika zara/Shutterstock.com

The study of tribology investigates the science and engineering of interacting surfaces in relative motion. The field draws in expertise across disciplines to determine and apply the principles of friction, lubrication, and wear.

From the Scanning Tunneling Microscope to the Atomic Force Microscope

Back in 1981, IBM scientists Gerd Binnig and Heinrich Rohrer developed the Scanning Tunneling Microscope, their work on which earned them the Nobel Prize in Physics in 1986. It was this instrument that first revolutionized the field of tribology. It allowed scientists to view the surfaces of materials at the atomic level, which opened up the door to more in-depth studies of how surfaces interact. A year later, Binning went on to develop the Atomic Force Microscope.

The original Scanning Tunneling Microscope was able to produce images of the surface of materials at the atomic level by scanning a sharp metal wire with an electrical voltage in its tip very close to the surface of the sample.

It relies on several principles, the quantum mechanical effect of tunneling, the piezoelectric effect, and finally, a feedback loop is also required to monitor the tunneling current and direct the tip’s position and the current.

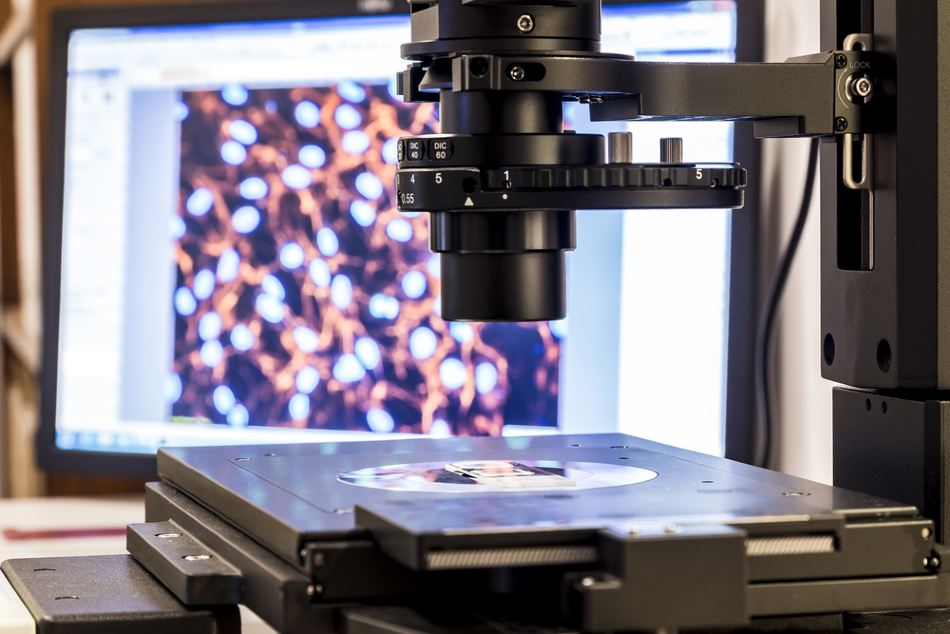

Atomic force microscopy (AFM), on the other hand, measures the force between the tip and the sample surface, instead of measuring the tunneling current. Because of this, the need for a sample conductivity became redundant and allowed for a whole new range of materials to be explored. Images produced with AFM have resolutions of up to fractions of a nanometer and are 1000 times better than the optical diffraction limit.

This advancement had a significant impact in the field of tribology as it equipped scientists and engineers with a tool to visualize the actions of friction, wear, and lubrication on a wide range of materials. This helps to enhance our understanding of the principles of tribology and to develop products and systems that rely heavily on this knowledge such as machinery using bearings, gears, cams, brakes and seals.

Key Findings from Using AFM in Tribology

Since the 1980s, AFM has been used to uncover the fundamental principles that apply to the different areas of tribology. The mysterious phenomenon of atomic-scale stick-slip behavior has been observed in many materials, where lateral forces exhibit stick-slip behavior with the periodicity of the lattice. AFM has successfully been used to uncover what determines the periodicity of the stick-slip behavior, helping scientists and engineers to better plan for this incident.

The frictional behaviors of plastic materials are significantly different from those of elastic materials. In the field of tribology, the occurrence of irreversible plastic deformation had long been a stand out issue. Since the 1980s, several AFM investigations have been carried out, uncovering the behavior of friction and wear in plastics, the results of which have allowed for far more accurate predictions to be made on how interactions with these materials will impact the physical parts involved.

AFM studies were also able to make significant advancements in our understanding of how lubricants work. A vast number of studies have been carried out that have been able to determine the ordered structure of the many monolayers of self-assembled (SAM) and Langmuir-Blodgett (LB) lubricants, such as their stacking surfaces. AFM has also been used to determine the key properties of these materials, such as their phase segregation of multicomponent systems, and nanoscale manipulation.

Modern AFM

Over the past several decades, the technology used by AFM has advanced and continues to offer an incredibly valuable tool to scientists and engineers working in tribology. The technique has established itself as a tool for fast scanning, producing images with high spatial resolution. It is valued for its excellent force sensitivity, and easy operation, allowing for the continued development of our understanding of nanoscale friction and wear.

Given that many fundamental aspects of tribology can only be explored by visualizing the nanoscale of the materials being tested, it is unsurprising how AFM has become synonymous with tribology.

References and Further Reading

https://pubs.acs.org/doi/abs/10.1021/cr960068q

https://www.sciencedirect.com/science/article/pii/0040609089905221

https://www.oxinst.com/news/afm-tribology-application-note/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.