Researchers have developed a new method for 3D printing metal that could help reduce costs and make more efficient use of resources.

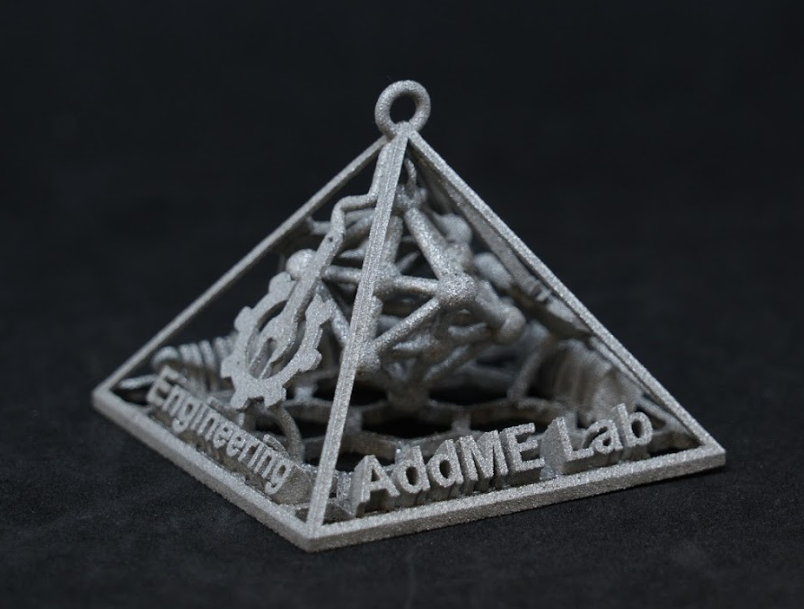

Image Credit: University of Cambridge

The method, developed by a research team led by the University of Cambridge, allows structural modifications to be programmed into metal alloys during 3D printing, fine-tuning their properties without the ‘heating and beating’ process that’s been in use for thousands of years.

The new 3D printing method combines the best qualities of both worlds: the complex shapes that 3D printing makes possible, and the ability to engineer the structure and properties of metals that traditional methods allow. The results are reported in the journal Nature Communications.

3D printing has several advantages over other manufacturing methods. For example, it’s far easier to produce intricate shapes using 3D printing, and it uses far less material than traditional metal manufacturing methods, making it a more efficient process. However, it also has significant drawbacks.

“There’s a lot of promise around 3D printing, but it’s still not in wide use in industry, mostly because of high production costs,” said Dr Matteo Seita from Cambridge’s Department of Engineering, who led the research. “One of the main drivers of these costs is the amount of tweaking that materials need after production.”

Since the Bronze Age, metal parts have been made through a process of heating and beating. This approach, where the material is hardened with a hammer and softened by fire, allows the maker to form the metal into the desired shape and at the same time impart physical properties such as flexibility or strength.

“The reason why heating and beating is so effective is because it changes the internal structure of the material, allowing control over its properties,” said Seita. “That’s why it’s still in use after thousands of years.”

One of the major downsides of current 3D printing techniques is an inability to control the internal structure in the same way, which is why so much post-production alteration is required. “We’re trying to come up with ways to restore some of that structural engineering capability without the need for heating and beating, which would in turn help reduce costs,” said Seita. “If you can control the properties you want in metals, you can leverage the greener aspects of 3D printing.”

Working with colleagues in Singapore, Switzerland, Finland and Australia, Seita developed a new ‘recipe’ for 3D printed metal that allows a high degree of control over the internal structure of the material as it is being melted by a laser.

By controlling the way that the material solidifies after melting, and the amount of heat that is generated during the process, the researchers can programme the properties of the end material. Normally, metals are designed to be strong and tough, so that they are safe to use in structural applications. 3D printed metals are inherently strong, but also brittle.

The strategy the researchers developed gives full control over both strength and toughness, by triggering a controlled reconfiguration of the microstructure when the 3D printed metal part is placed in a furnace at relatively low temperature. Their method uses conventional laser-based 3D printing technologies, but with a small tweak to the process.

“We found that the laser can be used as a ‘microscopic hammer’ to harden the metal during 3D printing,” said Seita. “However, melting the metal a second time with the same laser relaxes the metal’s structure, allowing the structural reconfiguration to take place when the part is placed in the furnace.”

Their 3D printed steel, which was designed theoretically and validated experimentally, was made with alternating regions of strong and tough material, making its performance comparable to steel that’s been made through heating and beating.

“We think this method could help reduce the costs of metal 3D printing, which could in turn improve the sustainability of the metal manufacturing industry,” said Seita. “In the near future, we also hope to be able to bypass the low temperature treatment in the furnace, further reducing the number of steps required before using 3D printed parts in engineering applications.”

The team included researchers from Nanyang Technnological University, the Agency for Science, Technology and Research (A*STAR), the Paul Scherrer Institute, VTT Technical Research Centre of Finland, and the Australian Nuclear Science & Technology Organisation. Matteo Seita is a Fellow of St John’s College, Cambridge.