Oct 20 2020

According to a new study by researchers from Japan and the United States, optical fiber data transmission can be considerably enhanced by making the silica glass fibers under high pressure. The study was published in the npj Computational Materials journal.

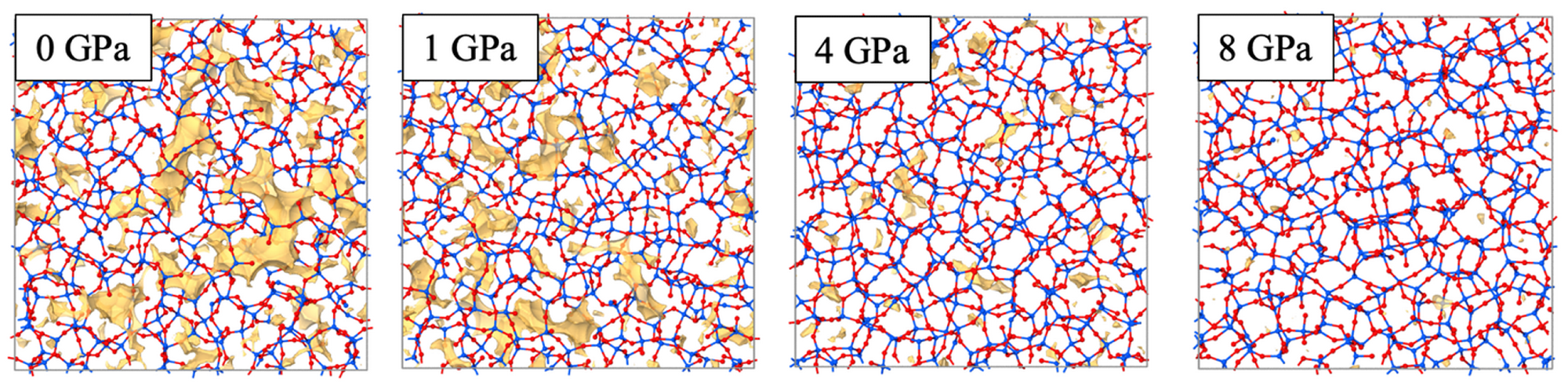

The voids in silica glass (yellow), which are responsible for the scattering of light and degradation of signals, become much smaller when the glass is quenched at higher pressures. Image Credit: Yongjian Yang, et al., npj Computational Materials, September 17, 2020.

The voids in silica glass (yellow), which are responsible for the scattering of light and degradation of signals, become much smaller when the glass is quenched at higher pressures. Image Credit: Yongjian Yang, et al., npj Computational Materials, September 17, 2020.

With the help of computer simulations, scientists at Hokkaido University, The Pennsylvania State University, and their industry partners theoretically demonstrate that signal loss from silica glass fibers can be decreased by over 50%, which could considerably increase the distance over which data can be conveyed without requiring amplification.

Improvements in silica glass, the most important material for optical communication, have stalled in recent years due to lack of understanding of the material on the atomic level. Our findings can now help guide future physical experiments and production processes, though it will be technically challenging.

Madoka Ono, Associate Professor, Research Institute of Electronic Science (RIES), Hokkaido University

Optical fibers have transformed high-bandwidth, long-distance communication across the globe. The cables that transport all that data are mostly made of fine threads of silica glass, somewhat thicker than a strand of human hair.

The material is flexible, strong, and excellent at conveying data, in the form of light, economically. However, the data signal diminishes before reaching its endpoint caused by the scattering of light.

Amplifiers and other tools are used to hold and transmit the data before it scatters, which ensures that it is delivered properly. Researchers are aiming to decrease light scatter, called Rayleigh scattering, to help quicken data transmission and transition closer toward quantum communication.

Ono and her colleagues used numerous computational approaches to envisage what occurs to the atomic structure of silica glass under high pressure and high temperature. They discovered the formation of large voids between silica atoms when the glass is heated up and subsequently cooled down, which is referred to as quenching, under low pressure.

However, when this process happens below 4 gigapascals (GPa), a majority of the large voids vanish and the glass takes on a much more even lattice structure.

Most notably, the models demonstrate that the glass undergoes a physical change, and smaller rings of atoms are removed or “pruned,” which enables larger rings to combine more closely. This allows the number of large voids and the average size of voids, which lead to light scattering, to be decreased and reduces signal loss by over 50%.

The team believes that even better advancements can be realized by using a slower cooling rate at higher pressure. The method could also be tested for other types of inorganic glass that have similar structures. But it is highly challenging to manufacture glass fibers under such high pressures at an industrial scale.

Now that we know the ideal pressure, we hope this research will help spur the development of high-pressure manufacturing devices that can produce this ultra-transparent silica glass.

Madoka Ono, Associate Professor, Research Institute of Electronic Science (RIES), Hokkaido University

Madoka Ono is part of the Laboratory of Nanostructured Functional Materials, RIES at Hokkaido University. The focus of her research work is on the properties of non-organic and silica glass by both computational analyses and lab experiments.

Journal Reference:

Yang, Y., et al. (2020). Topological pruning enables ultra-low Rayleigh scattering in pressure-quenched silica glass. npj Computational Materials. doi.org/10.1038/s41524-020-00408-1.