Jul 1 2019

Optical smoothing is considered as an extremely effective technique to limit mid-to-high spatial frequency errors produced by sub-aperture polishing technologies controlled by computers.

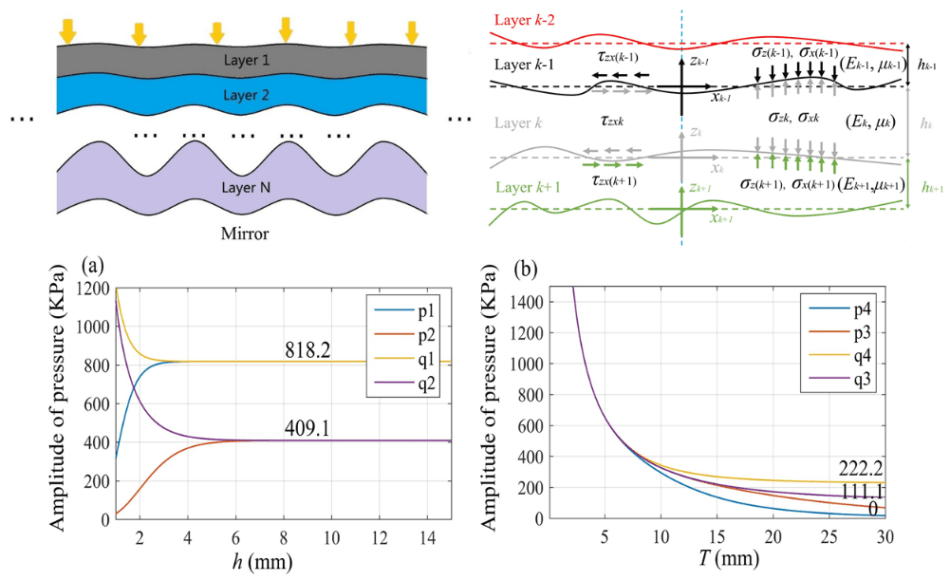

The model and result of pressure amplitude (Image credit: SIOM)

The model and result of pressure amplitude (Image credit: SIOM)

Preston equation states that pressure distribution is the main factor to elucidate the smoothing effect of a tool.

Despite the fact that pressure distribution can be solved by a traditional bridging model at the time of the smoothing process, it is only appropriate for a tool of rigid base, thin metal plate, compliant interlayer, and pitch polishing layer.

In the recent past, a team of researchers from the Shanghai Institute of Optics and Fine Mechanics (SIOM) of the Chinese Academy of Sciences determined a mathematical model to measure the pressure distributions between a mirror and a polishing tool for any kind of multi-layer polishing tool. The associated results have been reported in Applied Optics.

Predicated on Galerkins displacement functions, the shearing, bending, and compression deformation were all taken into account.

In the latest experiment, Cauchy equation and Hooke’s law were used to process the displacement and stress continuous conditions that exist between layers. Using a semi-flexible tool and a rigid tool as two examples, the researchers hypothetically compared in detail for their use in optical smoothing.

In this manner, validity and enhancement in precision of the pressure distribution model was verified by comparing with the finite element model, or FEM.

On the basis of the pressure distribution model, the overall stiffness of a tool was interpreted. The hypothetical comparison smoothing effects for varied polishing tools were performed by computing the ratio of their overall stiffness.

In addition, the researchers performed three sets of experiments by applying a semi-flexible tool as well as a rigid tool for smoothing 8- and 4-mm period errors produced by magnetorheological finishing, or MRF, to verify the model. Moreover, simulation result of the smoothing rates of the errors following every smoothing process was seen to correspond well with the experiment outcomes.

The excellent agreement of the hypothetical ratio with the experiment outcome shows that the recommended model is for diverse multi-layer polishing tools while smoothing varied mid-spatial frequency errors.