Feb 20 2019

According to Penn State researchers, an innovative type of light-emitting diode lightbulb shows promise to illuminate homes and also cut down power bills in the future.

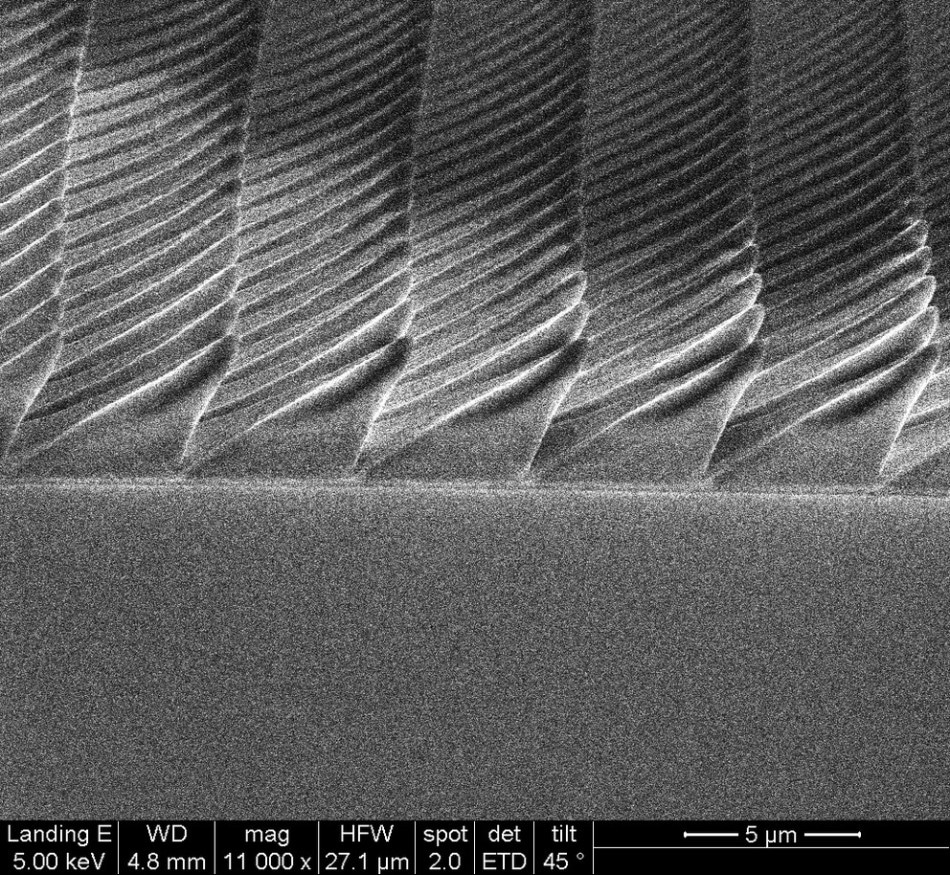

Scanning electron microscope image of the asymmetric pyramids that were 3-D nanoprinted. (Image credit: Penn State)

Scanning electron microscope image of the asymmetric pyramids that were 3-D nanoprinted. (Image credit: Penn State)

The researchers proposed that efficiency can possibly be improved using LEDs made out of firefly-imitating structures.

LED lightbulbs play a key role in clean energy. Overall commercial LED efficiency is currently only about 50 percent. One of the major concerns is how to improve the so-called light extraction efficiency of the LEDs. Our research focuses on how to get light out of the LED.

Stuart (Shizhuo) Yin, Professor, Department of Electrical Engineering, Penn State.

LEDs and fireflies face similar difficulties when it comes to emitting the light produced by them. The reason is that light is lost when it reflects backward. Texturing the surface with microstructures—very small projections—is one solution for LEDs. These microstructures enable more light to escape. Such projections in a majority of LEDs are symmetrical, with matching slopes on either side.

These microstructures are present in fireflies’ lanterns; however, the scientists observed that firefly lanterns contain asymmetric microstructures—that is, the sides slanted at various angles, providing a lopsided appearance.

Later I noticed not only do fireflies have these asymmetric microstructures on their lanterns, but a kind of glowing cockroach was also reported to have similar structures on their glowing spots. This is where I tried to go a little deeper into the study of light extraction efficiency using asymmetric structures.

Chang-Jiang Chen, Study Lead Author and Doctoral Student, Department of Electrical Engineering, Penn State.

By applying asymmetrical pyramids to produce microstructured surfaces, the researchers discovered that light extraction efficiency could be enhanced to about 90%. The results of the study have been recently published online in Optik and will appear shortly in the April print edition.

Yin stated that asymmetrical microstructures tend to boost light extraction in two methods. First, the asymmetric pyramids have a greater surface area, which increases the interaction of light with the surface, and as result, a less amount of light is trapped. Second, when light impinges on the two varied slopes of the asymmetric pyramids, it causes a bigger randomization effect of the reflections, providing light another chance to escape.

After the investigators applied computer-based simulations to demonstrate that the asymmetric surface may hypothetically enhance the extraction of light, they went on to show this experimentally. The team produced asymmetric and symmetric surfaces using nanoscale 3D printing, and subsequently determined the amount of light produced. The asymmetric surface enabled the release of more light, as anticipated.

With the growing demand for clean energy, the LED-based lighting market is expanding quickly and is projected to reach $85 billion by 2024.

“Ten years ago, you go to Walmart or Lowes, LEDs are only a small portion (of their lighting stock),” stated Yin. “Now, when people buy lightbulbs, most people buy LEDs.”

Compared to conventional fluorescent or incandescent lightbulbs, LEDs are more eco-friendly because they are more energy efficient and last for a long time.

A couple of processes play a role in the LEDs’ overall efficiency. The first process is the production of light—that is, the quantum efficiency—which is determined by the number of electrons transformed to light when energy travels via the LED material. In the case of commercial LEDs, this aspect has already been improved. The second process is called the light extraction efficiency, that is, removing the light from the LED.

“The remaining things we can improve in quantum efficiency are limited,” stated Yin. “But there is a lot of space to further improve the light extraction efficiency.”

The textured surfaces in commercially available LEDs are made on sapphire wafers. Initially, UV light is utilized for producing a concealed pattern on the sapphire surface that offers protection from chemicals. When chemicals are subsequently applied, they produce the pyramid array by dissolving the sapphire around the pattern.

You can think about it this way, if I protect a circular area and at the same time attack the entire substrate, I should get a volcano-like structure.

Chang-Jiang Chen, Study Lead Author and Doctoral Student, Department of Electrical Engineering, Penn State.

In the case of traditional LEDs, symmetrical pyramids are usually produced during the production process; this is due to the orientation of the sapphire crystals. The researchers noted that if the block of sapphire is cut at a tilted angle, the same process will produce the lopsided pyramids, Chen said. The investigators modified only one part of the manufacturing process, proposing that their method may easily be used for commercial development of LEDs.

A patent on this study has been filed by the researchers.

Once we obtain the patent, we are considering collaborating with manufacturers in the field to commercialize this technology.

Stuart (Shizhuo) Yin, Professor, Department of Electrical Engineering, Penn State.

Jimmy Yao, Wenbin Zhu, Ju-Hung Chao, Annan Shang, and Yun-Goo Lee, doctoral students in electrical engineering, were other researchers who worked on this study.