Feb 16 2015

Panasonic Corporation today announced that it has developed the industry’s largest*1 glass-molded aspheric lens measuring 75 mm in diameter that can be used for interchangeable lenses for cameras and projectors whose size and resolution have been increasingly reduced and enhanced, respectively. The shipping of samples of this large-diameter aspheric lens will start from February 13, 2015. We will also commence with external sales of these lenses.

*1: In the category of glass-molded aspheric lenses. As of February 13, 2015, according Panasonic’s data

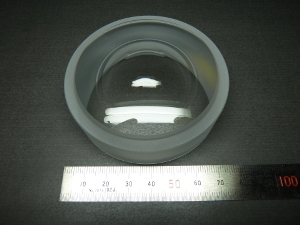

Glass-molded aspheric lens: 75 mm in diameter (Photo: Business Wire)

Glass-molded aspheric lens: 75 mm in diameter (Photo: Business Wire)

Interchangeable lenses for cameras and projectors are required to be small with a high resolution, in addition to conforming to the trend of having a large diameter and wide angle. There have been growing needs for large-diameter aspheric lenses that help reduce the number of parts involved.

We have developed the industry’s largest*1 glass-molded aspheric lens/mirror with a diameter of 75 mm by taking full advantage of our engineering capabilities and production expertise that have been refined through development and production of LUMIX digital cameras and other products. We have also established mass production technology for preventing cloudiness and cracks and for maintaining shape precision in the process of molding large-diameter lenses. This lens enables a reduction in the number of parts by about 25% compared with comparable conventional products.

These lenses have the following features.

- Developing the industry’s largest*1 glass-molded aspheric lens/mirror measuring 75 mm in diameter

Capable of reducing the total length by 30% compared with interchangeable spherical lenses of the same performance

- Ensuring thermal resistance and minimizing thermal expansion through the use of glass materials

Achieving thermal resistance (250°C or higher) and low thermal expansion (about 1/10 that of plastics) that cannot be attained using plastic materials

- Achieving high reliability and high refractive index of varying degrees by using our proprietary mass production technologies and production expertise

Achieving high processing precision and high refractive index of varying degrees by using in-house developed molds and molding/measurement equipment as well as proprietary expertise

The lens has been used in ET-D75LE90, an optional lens commercialized in November 2014 for our ultra-high-brightness projectors, to achieve short-throw wide-angle projection. We will start shipping samples of this large-diameter aspheric lens as a key device that meets the needs of our corporate customers.

The latest product enhances our lineup of aspheric lenses ranging from 1 mm (for endoscopes) to 75 mm in diameter. We will expand our business-use lens operations to various industries based on the latest large-diameter glass-molded aspheric lens in order to increase sales.