When cement raw materials are calcined in the kiln, a material known as clinker is obtained. It is important to closely monitor lime in clinkers. Undesirable effects such as increased setting time, reduced strength or volume expansion can result from excess free lime.

Furthermore, to obtain maximum reactivity and reduce thermal consumption, the operator can determine and maintain the optimum operating point of the kiln by monitoring free lime constantly. Raw meal grinding can also be reduced, resulting in further economies of energy with high reactivity.

The ideal technique for performing chemical elemental analysis on cement-making materials is the X-Ray fluorescence technique (XRF), from which concentration for the major oxides is derived. Separate X-Ray diffractometry (XRD) equipment or wet chemical methods such as titration is required to determine the phase content in clinker or cement as mineralogical information is not available from XRF spectra.

An innovative instrument that can handle both techniques, the Thermo Scientific ARL 9900 series with IntelliPower is a diffraction system that can perform qualitative analysis and qualitative scans.

The highest repeatability of angular positioning is ensured by the Thermo moiré fringe positioning mechanism. Careful optimization of the crystal discriminator and the detector has generated an improvement in the performance of this diffraction system.

Free Lime Analysis Results

For free lime, six clinker standards were analyzed. Two 200 mg grinding pills were used to grind the powders for 10 seconds. First, they were pressed into pellets at 15 t for 40 seconds and measured on the ARL 9900.

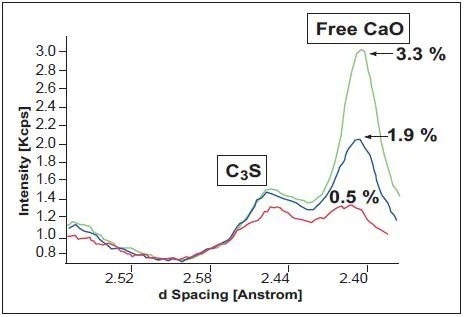

Figure 1 shows the diffractogram recorded with the diffraction system on three different clinker pellets. As can be observed, two peaks assigned to C3S and CaO phases are resolved and no fluorescence from the sample interferes with this.

Figure 1. Diffraction pattern obtained with the ARL 9900 Series in the free lime region for clinker samples with varying CaO concentrations. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

From the peak representing 0.5% of free lime, it can be seen that the increased sensitivity of the diffraction system is more than enough to monitor the free lime content even at low levels (0.1% to 0.5%).

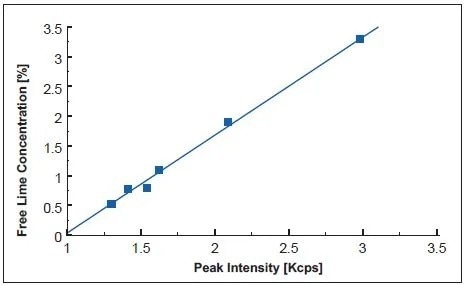

With the calibration program, the intensities of the characteristic diffraction peak for free lime (d=2.41Å) on the six clinker standards is recorded. Figure 2 displays the results and the relevant parameters in Table 1.

A sensitivity of 600 cps % for free lime analysis is produced by the innovative diffraction system – approximately 10 times greater than a conventional X-Ray diffractometer. The standard error of estimate is the average of the differences between chemical and found concentration. The value obtained (0.08 %) is well within wet chemistry’s capability.

Figure 2. Calibration curve of free lime in clinker using the ARL 9900 Series. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Peak Intensity [Kcps]

With the integrated XRD system, a clinker sample was measured 11 times for 40 seconds on free lime and measured for 40 seconds on the fixed XRF channels. By measuring a clinker sample 11 times for 40 seconds on free lime with the integrated XRD system (and 40 seconds on the fixed XRF channels), the short-term stability was tested.

Table 2 summarizes the results where XRF results on major oxide are also included for comparison.

Approximately 1% relative standard deviation shows the fine repeatability of the system (a measure approximately 10 times that which is achievable by wet chemistry). The final step was a long-term stability test that was carried out for 50 hours. With sigma values well within statistics (1.8% free lime ±0.02%), excellent results were obtained.

Table 1. Regression results on free lime. Source: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

| |

CONCENTRATION |

| SAMPLE DIFFERENCE ABSOL. % |

NAME |

Kcps |

NOM. % |

CAL’D% |

| Clinker 1 |

1.54 |

0.80 |

0.93 |

0.13 |

| Clinker 2 |

1.30 |

0.53 |

0.53 |

0.00 |

| Clinker 3 |

2.98 |

3.30 |

3.32 |

0.02 |

| Clinker 4 |

1.62 |

1.10 |

1.07 |

-0.03 |

| Clinker 5 |

2.09 |

1.90 |

7.84 |

-0.06 |

| Clinker 6 |

1.41 |

0.77 |

0.71 |

-0.06 |

| Standard error of estimate |

0.08% |

|

| BEC |

1.636% |

|

| Q (sensitivity) |

600 cps% |

|

| Limit of Detection |

156ppm |

|

Table 2. Typical reproducibility (10 runs) of free lime analysis in clinker. Source: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

| RUN |

XRD FREE LIME |

CaO |

SiO2 |

Al2O3 |

Fe2O3 |

MgO |

K2O |

Na2O |

SO3 |

| 1 |

0.67 |

65.54 |

21.42 |

5.59 |

3.97 |

1.55 |

0.68 |

0.58 |

1.01 |

| 2 |

0.68 |

65.52 |

21.41 |

5.59 |

3.96 |

1.55 |

0.68 |

0.58 |

1.00 |

| 3 |

0.67 |

65.52 |

21.41 |

5.59 |

3.96 |

1.55 |

0.68 |

0.58 |

1.00 |

| 4 |

0.66 |

65.50 |

21.40 |

5.58 |

3.96 |

1.55 |

0.68 |

0.58 |

1.00 |

| 5 |

0.67 |

65.50 |

21.39 |

5.58 |

3.96 |

1.55 |

0.68 |

0.58 |

1.00 |

| 6 |

0.66 |

65.52 |

21.41 |

5.58 |

3.96 |

1.55 |

0.68 |

0.58 |

1.01 |

| 7 |

0.66 |

65.52 |

21.41 |

5.59 |

3.96 |

1.54 |

0.68 |

0.58 |

1.00 |

| 8 |

0.67 |

65.51 |

21.41 |

5.58 |

3.96 |

1.55 |

0.68 |

0.58 |

1.00 |

| 9 |

0.67 |

65.51 |

21.41 |

5.59 |

3.96 |

1.55 |

0.68 |

0.58 |

1.00 |

| 10 |

0.65 |

65.50 |

21.39 |

5.59 |

3.96 |

1.55 |

0.68 |

0.58 |

1.00 |

| Average |

0.67 |

65.51 |

21.41 |

5.59 |

3.96 |

1.55 |

0.68 |

0.579 |

1.00 |

| St Dev |

0.007 |

0.014 |

0.011 |

0.009 |

0.004 |

0.003 |

0.001 |

0.002 |

0.001 |

| RSD |

1.04 |

0.02 |

0.05 |

0.16 |

0.10 |

0.18 |

0.09 |

0.27 |

0.08 |

Conclusions

As a result of the high sensitivity and excellent stability of the diffraction system integrated into the ARL 9900, free lime in the clinker can be easily quantified. Utilizing this integrated XRF-XRD instrument, users can also monitor limestone additions to cement, as well as other clinker phases like C3S, C2S, C3A or C4AF.

There are a range of benefits of this combined system, including:

- The possibility of performing XRF and XRD under identical conditions on the same sample, ensuring stable and reliable total analysis and thus eliminating all extra costs for additional hardware

- XRF performance is not affected by adding this diffraction system

- Data treatment methods and software are common to XRF and XRD measurements.

Complete quality control of clinker and cement is offered by integrating XRF and XRD in the same instrument. Significant savings as a result of increased operator efficiency, lower maintenance, and reduced running costs result from the fact that separate instruments or methods are no longer required.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.

For more information on this source, please visit Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.