Heterogeneous catalysis is approximately 90 vol% of the production of chemicals worldwide and is essential to both guide a chemical reaction to the desired product and for the reduction of the energy needed for this process.

Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

The active surface of the catalyst is the most important part of heterogeneous catalysis, which achieves the best efficiency. Activated base materials, generally ceramics with a large surface area or carbon, are infused with nanoparticles of metal, the active compound, as a result of this.

Measuring the size of the nanoparticles, particularly after the materials have been recycled, is one method of gauging the quality of the catalyst. X-Ray diffraction (XRD) is the most widely used method to define the size of the nanoparticles’ crystallite.

Through Scherrer’s equation, the peak width of reflections with XRD directly correlates to the size of the scattering domain. As a result, it is possible to conclude the crystallite size (CS) by determining the width of reflection in the diffraction pattern.

Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

The Thermo Scientific™ ARL™ EQUINOX 100 X-Ray Diffractometer

The Thermo Scientific™ ARL™ EQUINOX 100 X-Ray Diffractometer utilizes a custom-designed Cu (50 W) micro-focus tube with mirror optics for high flux, which means no external water chiller is needed.

Thanks to its unique curved position sensitive detector (CPS), the ARL EQUINOX 100 Diffractometer can offer rapid data collection times which measure all diffraction peaks concurrently. The ARL EQUINOX 100 Diffractometer is, as a result, perfect for measuring transmission and reflection.

Case Study

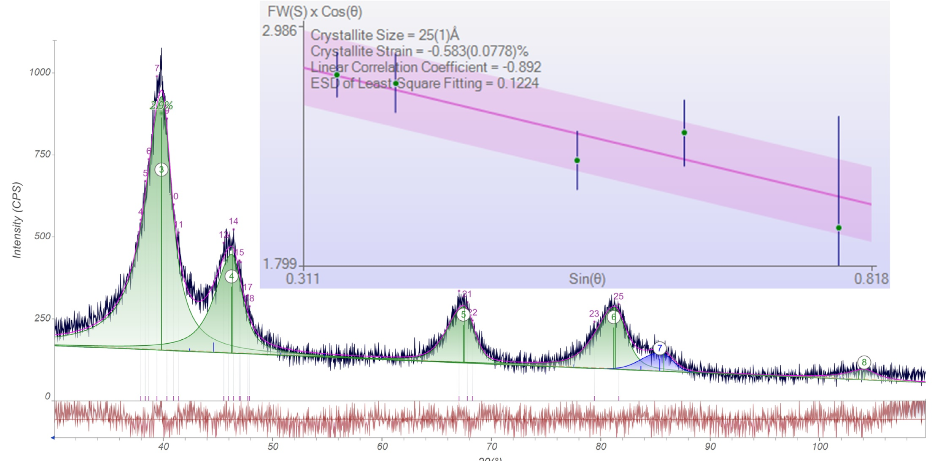

For XRD measurements, Pt/C powder was measured 5 minutes in reflection with a zero-background sample cup. MDI JADE 2010 was used to determine the crystallite size using the Williamson-Hall method.

Results

To determine the FWHM of the reflections, a Le Bail fit was utilized. Next, the Williamson-Hall method (cf. Figure 1) was used to calculate CS. Strain and instrument broadening, defined from NIST660 LaB6, was also taken into consideration. Refinements provided a CS of 2.5 nm. This result aligns strongly with values seen in literature.

Figure 1. Diffraction pattern of Pt/C (green: Pt; blue: C); Williamson-Hall plot of Pt/C (Red area indicates 1.5 σ). Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Summary

The benchtop ARL EQUINOX 100 X-Ray Diffractometer proves to be a convenient solution for those wishing to quickly and easily determine the CS of Pt nanoparticles in Pt/C catalysts, particularly when used in conjunction with the MDI JADE 2010 Software suite.

Acknowledgments

Produced from materials originally written by Dr. Simon Welzmiller from Thermo Fisher Scientific.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.

For more information on this source, please visit Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.