The term “heavy fuel oil” is used to refer to the non-boiling residuum of refined crude oils and the highest boiling-point distillate fractions. It is used as fuel for boilers, industrial heaters, and engines.

Figure 1. Ocean-going ship. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

In order to power the huge compression ignition engines of the world’s ocean-going ships in the marine fuel market (Fig. 1), 54% of the total recent global production of 530 Mt of heavy fuel oil was consumed.

Within the industry, terms like ‘marine fuel oil’, ‘residual marine fuel’, and ‘bunker fuel oil’ are used to refer to the ten different fuel grades outlined by the ISO 8217 (2005) marine fuel standard.

Natural contaminants found in crude oil are tied up in complex non-volatile asphaltene and porphyrin molecules, which include vanadium, sulfur, iron and nickel. These elemental contaminants are concentrated in the heaviest distillate fractions associated with heavy fuels; refining process contaminants are also strongly present in these streams.

Within oxygen-rich combustion engine environments and at high temperatures, the interaction and concentration of such corrosive and abrasive elemental contaminants can have a significant detrimental impact – even cutting down equipment service life by up to 80%. This means that marine residual fuels must adhere to comprehensive quality specifications even if market prices are low.

Table 1 shows the specifications that specifically guard against the dumping of used oil during storage.

Table 1. Elemental contaminants controlled by ISO 8217 marine fuel standards. Source: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

| Element |

Performance factors |

Limit (max)† |

| Sulphur (S) |

Corrosive wear, greenhouse emissions |

1.0-4.5% m/m |

| Vanadium (V) |

Corrosive wear, particulate emissions |

100-600 mg/kg |

| Aluminum (Al) + Silicon (Si) |

Abrasive wear |

25-80 mg/kg total |

| Zinc (Zn) |

Used oil contaminant |

15 mg/kg |

| Phosphorous (P) |

Used oil contaminant |

15 mg/kg |

| Calcium (Ca) |

Used oil contaminant |

30 mg/kg |

†- ranges include lighter Distillate Fuel grades (low limits) to heaviest Residual grades (higher limits).

Standard Test Methods

Wavelength dispersive X-Ray fluorescence (WDXRF) is specifically referenced by the ISO 8217 marine fuel standard as a preferred analysis method for vanadium, sulfur, and nickel analysis per ISO test methods 14596 and 14597.

A number of advantages are offered by the WDXRF method, including simple sample preparation, speed of analysis, and excellent precision and stability across multiple elements from ppm to percentage concentrations.

Moreover, a new industry test was proposed in 2009 by the British Institute of Petroleum (IP) specifically for WDXRF analysis of residual fuel oil. The use of the Thermo Scientific ARL OPTIM’X spectrometer for analysis of heavy residual fuel oil per typical international test protocols is evaluated in this article.

Instrumentation

A wavelength dispersive XRF instrument, the ARL OPTIM’X has been expressly designed for quick deployment, ease of use, and lower operational costs. As shown in Figure 2, it has been proven that thanks to its unique Ultra Closely Coupled Optics, the low power 50 W Rhodium target X-Ray tube offers equivalent sensitivity to conventional 200 W instruments.

Figure 2. Innovative UCCO technology. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

The resulting analytical sensitivity for even ultra-low contaminant concentrations rivals that of higher powered and more expensive WDXRF instruments while providing full capabilities at high concentrations, e.g., 4.5% sulfur. Furthermore, thanks to the efficient low power system of the ARL OPTIM’X, the system does not require the same auxiliary water cooling as larger instruments.

All elements of interest in heavy fuels from Na (Z=11) to Zn (Z=30) or heavier are covered by the sequential analysis capabilities of the patented SmartGonio miniaturized goniometer. The goniometer also offers a spectral resolution that is ten times better than high-end energy dispersive X-Ray fluorescence (EDXRF) instruments.

The unique design of the ARL OPTIM’X also includes optional enhanced performances on selected elements with the configuration of two MultiChromator fixed channels, in which specially curved and focused crystals further reduce analysis time and enhance sensitivity (Figure 3).

Figure 3. Thermo Scientific ARL OPTIM’X Series. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Sample Preparation and Procedure

Significant benefits are offered by WDXRF when it comes to analyzing even highly viscous samples without dilution. For sample preparation to take place, fuel samples must be poured (with heating as necessary) directly into Chemplex liquid analysis cells sealed with 4 µm polypropylene (Spectrolene) film.

An ARL OPTIM’X was configured for this study with both several fixed channel MultiChromators for enhanced analysis of certain elements and the SmartGonio for sequential elemental analysis. To eliminate air interferences, samples were analyzed for 120 seconds.

Analytical Sensitivity

The sensitivities obtained with the MultiChromator fixed channels in comparison with those obtained with the SmartGonio crystal and detector combination are shown in Table 2.

The ARL OPTIM’X, with its SmartGonio configuration, offers very low limits of detection for virtually all contaminant elements in heavy fuels and those well within the quality limits set by ISO 8217. An additional fixed channel configuration provides further sensitivity for the more challenging lighter elements.

Table 2. Instrument configurations and analytical sensitivity. Source: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

| Element |

SmartGonio

configuration |

SmartGonio

LOD [ppm] |

Fixed channel

LOD [ppm] |

| Al |

PET/FPC |

4.2 |

3.1 |

| Si |

PET/FPC |

4 |

3.2 |

| P |

PET/FPC |

2 |

1.5 |

| S |

PET/FPC |

1.7 |

1.2 |

| Ca |

LIF200/FPC |

1.5 |

1.7 |

| V |

LIF200/FPC |

1 |

n.m. |

| Fe |

LIF200/FPC |

1.1 |

0.8 |

| Ni |

LIF200/SC |

0.6 |

n.m. |

| Zn |

LIF200/SC |

0.6 |

n.m. |

Reproducibility

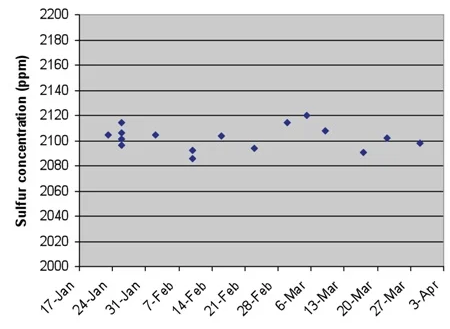

Highly stable analytical results over time are offered by the design of the ARL OPTIM’X. Figure 4 shows the repeatability over a two-month period on the same medium-range sulfur sample of 2.1 % (2,100 ppm). The instrument provides reproducible results over time without the need for recalibration with an average value of 2,102 ppm and a standard deviation of 9.5 ppm or 0.44 %,

Figure 4. Reproducibility of the results over a two month period. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Conclusion

Heavy residual fuels must adhere to tight quality restrictions to ensure proper marine engine performance, despite the fact that heavy residual fuels occupy the lower end of the distillate fuel spectrum.

Analysis needs to be done with excellent analytical flexibility and sensitivity in order to measure the percentage of element concentrations, given that the ppm levels of tolerated contaminants are very low.

A uniquely designed, cost-effective WDXRF instrument, the ARL OPTIM’X, exceeds the requirements of ISO 8217 and other international standards for range, sensitivity, and reliability of heavy fuel analysis.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.

For more information on this source, please visit Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.