Flexible electronics open up a whole new realm of potential applications in the fields of wearables, thin film solar cells, RFIDs and displays that are regularly used in medical applications or automotive dashboards. For each one of these use cases, a key quality indicator is product reliability.

There is also an increasing demand for components to be harmonized for communication, energy generation and signal processing.

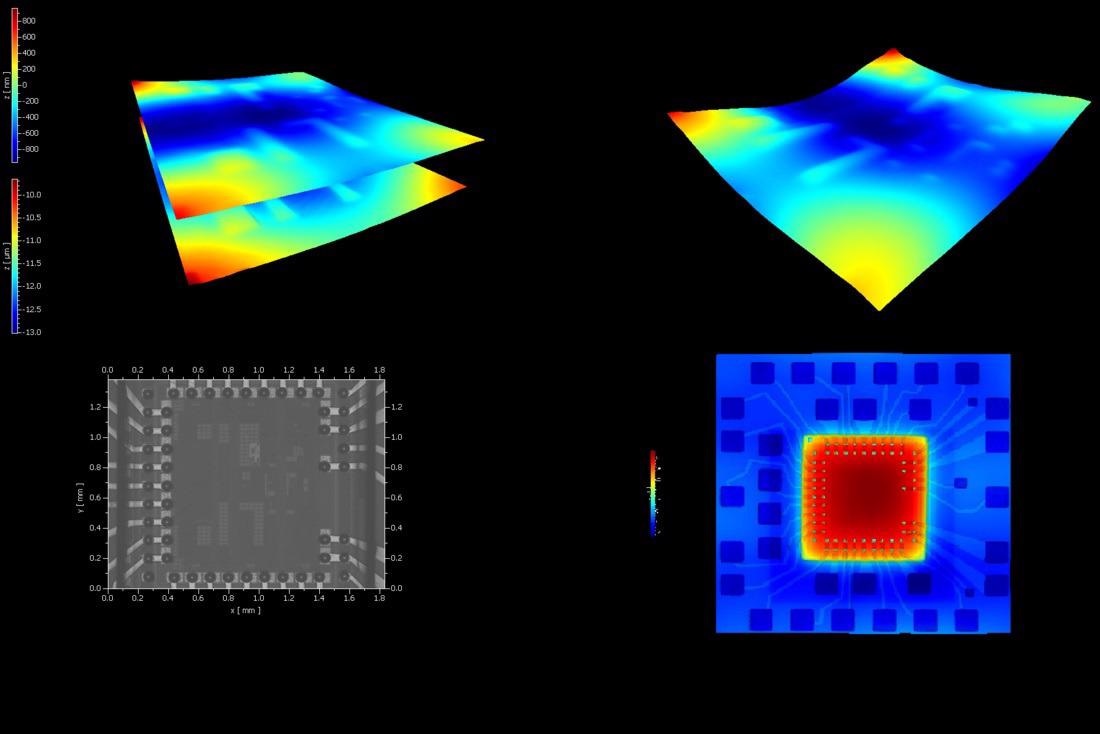

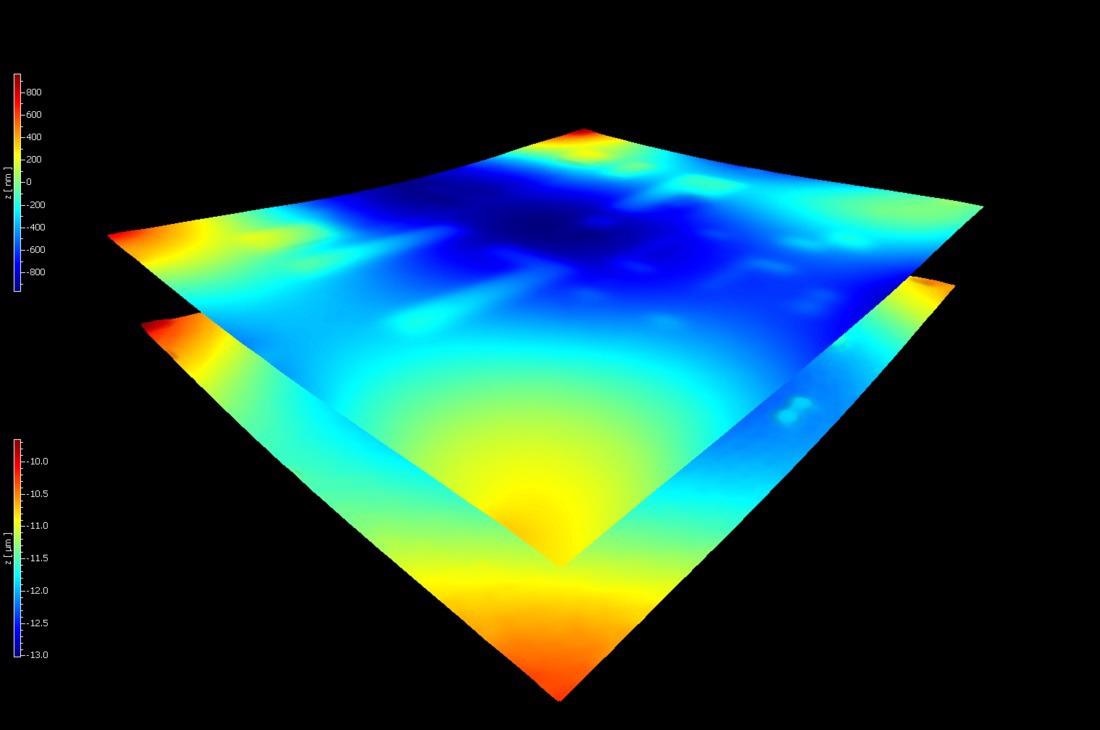

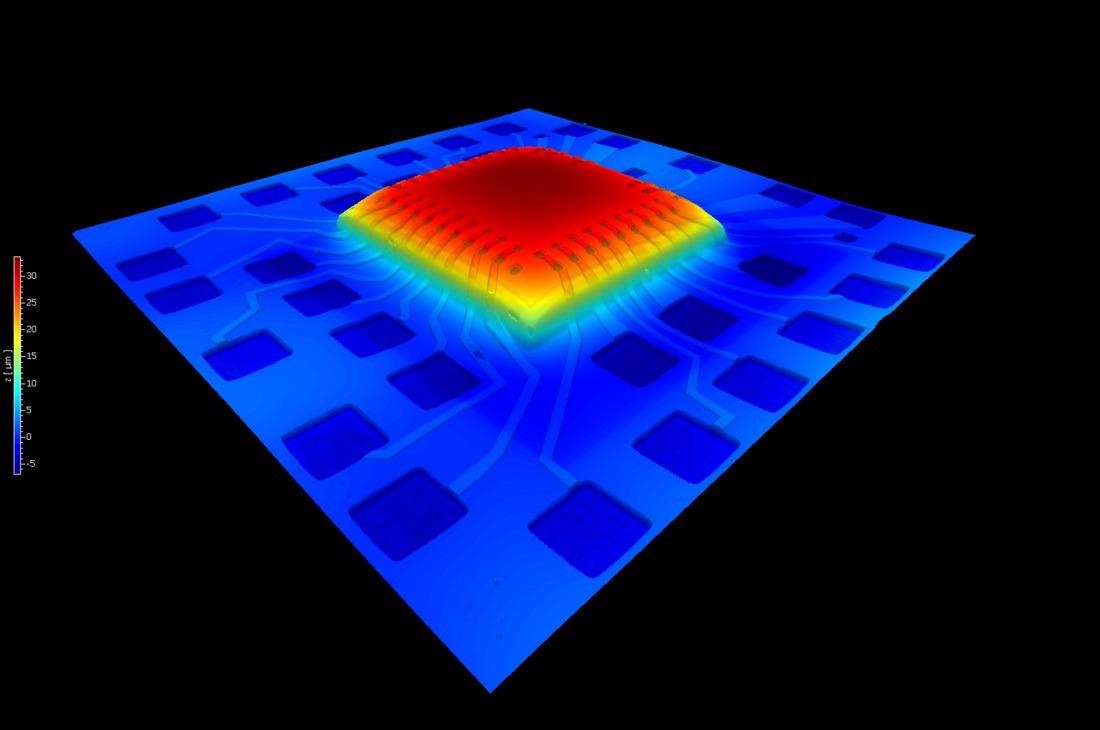

White-light interferometry allows the entire surface of hybrid flexible electronics to be scanned in a single shot for such applications. The non-destructive optical measurement technique characterizes printed electronics on behalf of form parameters, roughness and structural details and helps secure the functionality and quality of electronics.

Surface Roughness & Form Parameters of Printed Electronics

Evaluating 3D height information and scanning surfaces ensures a reliable and fast characterization of printed and flexible electronics. Meaningful data for printed electronics process stability is provided by 3D surface metrology solutions from Polytec. Determining and localizing defects is simplified by the advanced color information mode.

TopMap sensor heads can easily be integrated into production lines, offering customized solutions for in-line inspection when it comes to in-line integration and for semi- or fully automated manufacturing processes of flexible electronics.

Users or a PLC can manage and load predefined measurement settings on-demand, which at production levels allows the use of one-click inspections using measurement recipes.

PolyXperts are happy to assist clients in using the open software architecture at all project stages, including developing custom routines and evaluations.

Visit the Polytec PT section for polymer technology solutions for more information about how to master electrically conductive bonding of flexible electronics.

Image Credit: Polytec

Image Credit: Polytec

Image Credit: Polyte

This information has been sourced, reviewed and adapted from materials provided by Polytec.

For more information on this source, please visit Polytec.