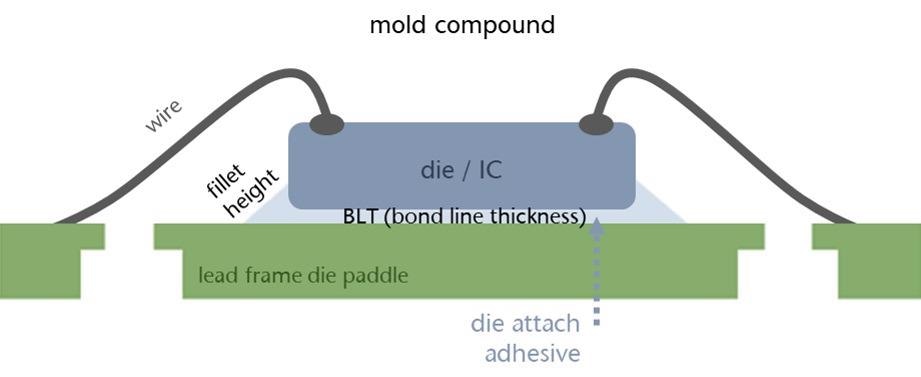

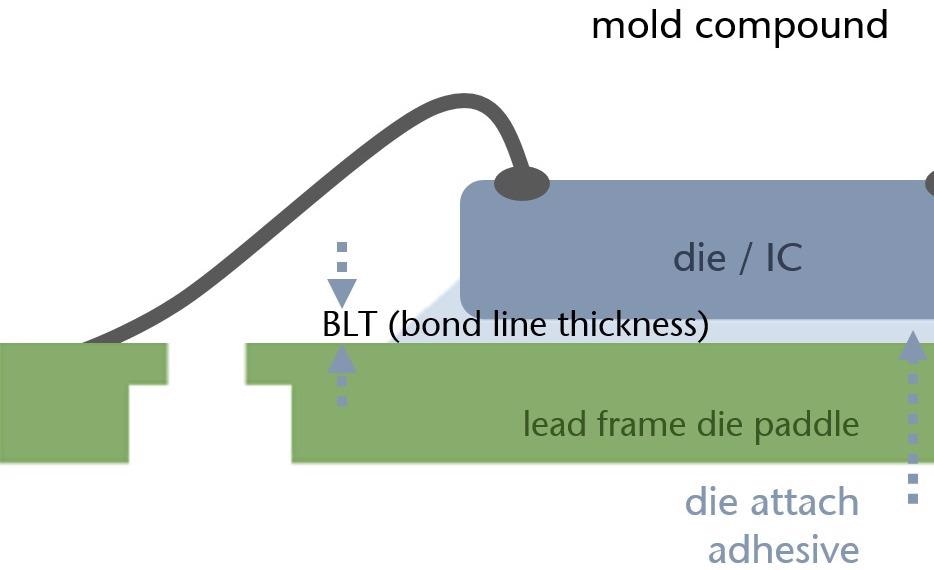

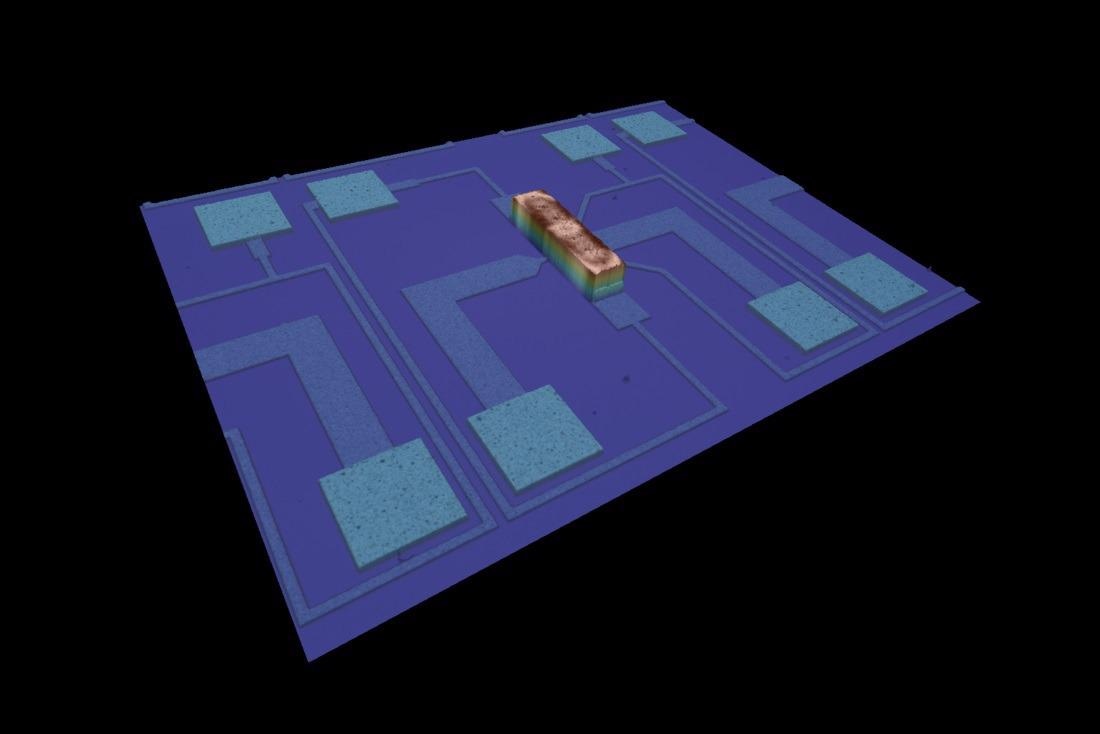

The accurate placement and attachment of the die in epoxy die bonding and any related die attach processes is essential for component quality and process stability. The adhesive thickness and bond line thickness (BLT) are key to a reliable die attach to a lead frame or other substrates.

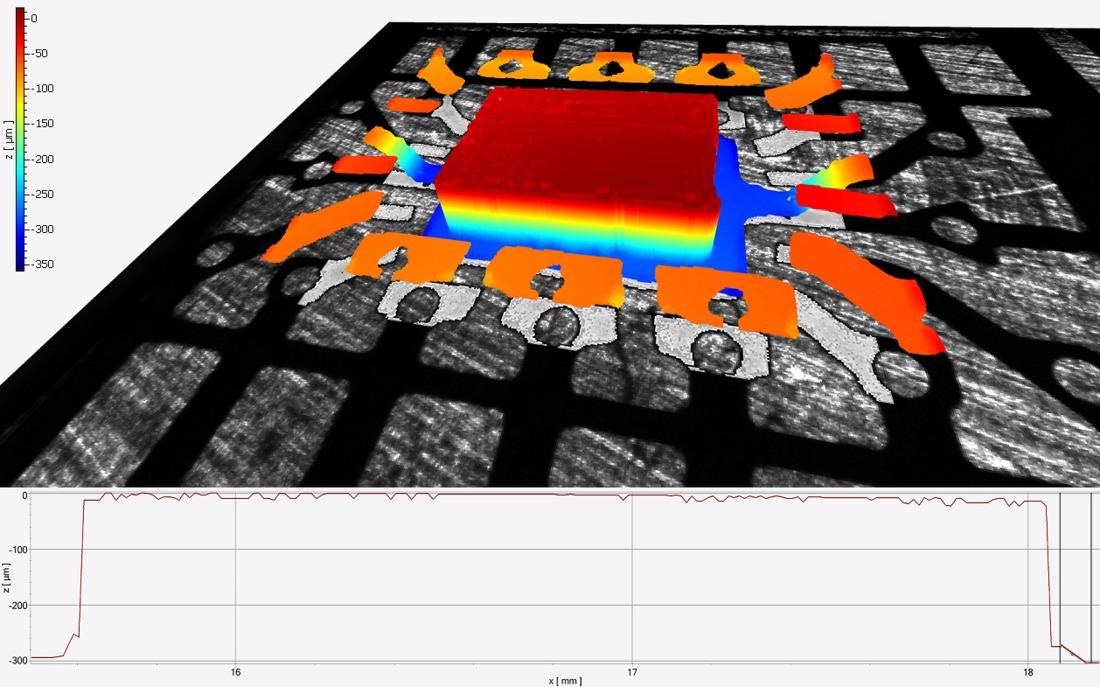

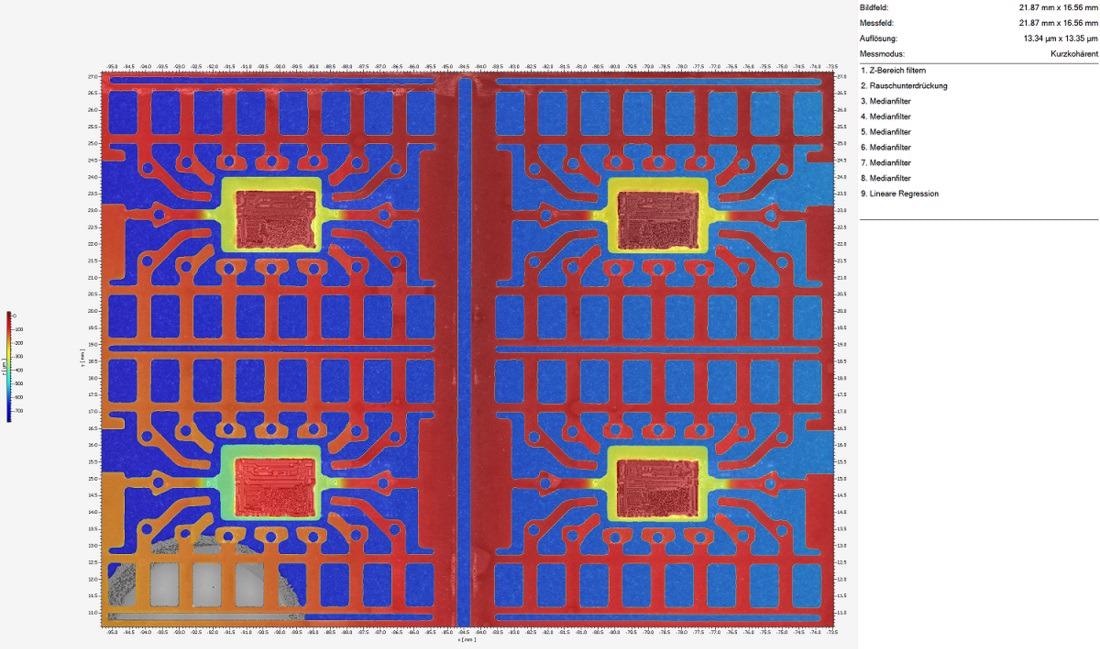

A reliable and automatic determination of the die orientation on the lead frame, including the die tilt as well as bond line thickness measurement, is facilitated by TopMap surface profilers from Polytec. A fast, simple and reliable quality control of the die bonding process is ensured by this non-contact measuring method.

Distinguishing QFN packages (quad-flat no-leads)

It is easy to integrate 3D surface metrology solutions from Polytec into production lines and therefore obtain high-resolution and automated in-process measurements within the epoxy die bonding process.

The torsional information and relative measurement to a reference position, bond line thickness measurement (BLT), determination of the die tilt, and the BLT height or die/ chip positioning are all typical measurements taken.

In quad-flat no-leads (QFN) packages, one of the standard chip connect types in integrated circuits, the die attach fillet is an excess climbing on the edge of the die. The die attach fillet offers mechanical strength along the die edges.

The useful and optimized parameters can be derived from the measured bond line thickness, including the height of the fillet from the pad, the width of the fillet, the slope angle or the slope of the rise of the fillet.

Image Credit: Polytec

Image Credit: Polytec

Image Credit: Polytec

Image Credit: Polytec

Image Credit: Polyte

This information has been sourced, reviewed and adapted from materials provided by xx.

For more information on this source, please visit Polytec.