Over the past 10 years, Raman has come into its own, making the jump from the laboratory to industry and the field with compact, field-portable analysis systems. However, as with many technologies, the size reduction has frequently led to performance compromises in comparison to conventional benchtop Raman systems.

This has restricted the applications in which compact Raman spectroscopy can be applied, and/or the achievable detection limit. Yet, it is still possible to widen the scope of compact Raman to reduce this gap and allow new applications through a carefully engineered product design that optimizes size, sensitivity, and wavelength.

Designing a compact, field-portable system for Raman that comes close to matching the performance of a benchtop system requires care and attention to three vital parameters that can provide both researchers and OEMs with significant advantages:

- Sensitivity – using improved optical designs to produce considerably more throughput in the same compact footprint without significantly increasing the cost

- Miniaturization – sturdy, sophisticated mechanical design that minimizes footprint while supplying excellent thermal stability and unit-to-unit reproducibility

- Wavelength – optimization of analysis wavelength(s) to get the greatest SNR for each sample

The article examines the relevant design options to optimize each, and consider how they can push the boundaries of applied Raman spectroscopy by offering a step change in the conventional performance of compact spectrometers, as well as other available products.

Sensitivity – The Wasatch Advantage

Sensitivity is highly important, as it is vital to some of the most intriguing commercial Raman applications currently breaking through including high-throughput inspection, through-package analysis, trace level detection, and tagging.

The traditional compact crossed Czerny-Turner (CCT) fiber optic spectrometers that have been on the market for 20 years can serve many routine identification tasks, but they still fail to match benchtop spectroscopy systems by 1-2 orders of magnitude. This is due to certain restrictions in this particular optical layout, thus an improved optical design is required to deliver significantly more throughput in the same compact footprint.

The early miniature, compact spectrometers were designed for “good enough” spectroscopy. Making use of the lowest cost possible components in a configuration deemed the most compact, the aim was to achieve a single-shot spectrum with resolution and sensitivity suitable for routine absorption or reflection spectroscopy.

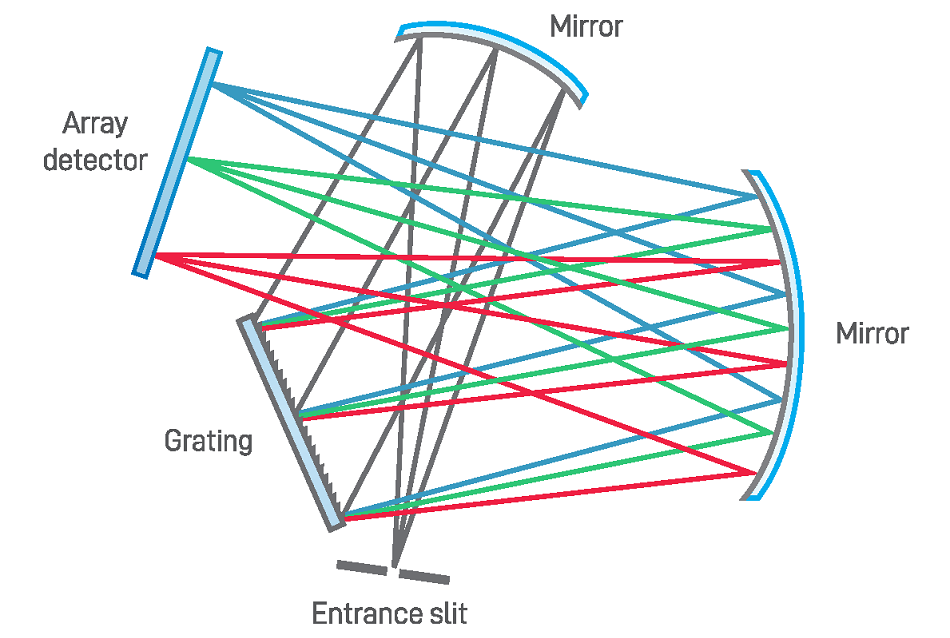

Their numerical aperture was chosen to match the most common multimode fibers available – 0.22 NA – and thus use an f/4 optical design. An f/4 crossed Czerny-Turner (CCT) optical layout using reflective optics maintains a minimum size but at a significant cost: the effects of the asymmetric design leads to a curved image plane on the detector, making it increasingly difficult to mitigate for optical aberrations, and deteriorating peak symmetry with temperature.

While several applications are well-suited to this design, it must make greater effort concerning the two key performance parameters most crucial to applied portable Raman spectroscopy – sensitivity and thermal stability.

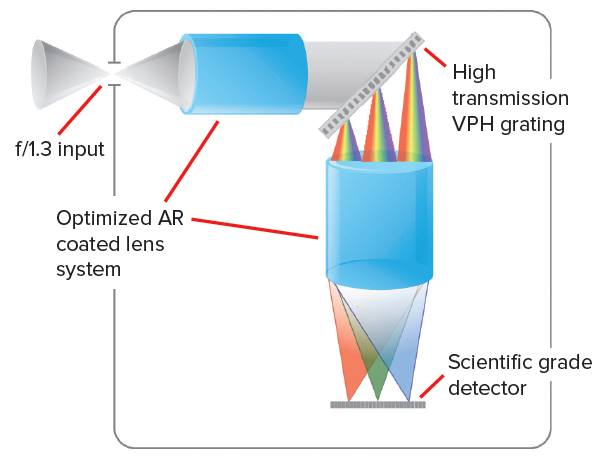

The compact spectrometer from Wasatch Photonics, that is specifically designed for Raman, takes a unique approach – by working in transmission instead of reflection, optical aberrations can be limited to below the diffraction limit, reducing stray light in the system and accomplishing constantly good focus over the detector image plane for more signal.

The use of VPH transmission gratings provides an additional 20-40% increase in efficiency over the reflective gratings used in CCT spectrometers, in addition to a smoother varying response curve and little scatter. Sensitivity gains can be further amplified by increasing the collection angle to 42° (f/1.3 vs the typical f/4 of a CCT spectrometer, or a 0.36 NA).

Combined, these factors result in >10x more signal by design. This enhancement in optical design converts into multiple material advantages in terms of relative performance as described below.

Higher Sensitivity

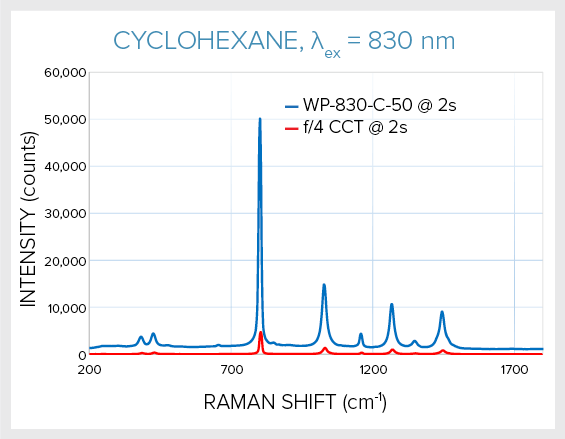

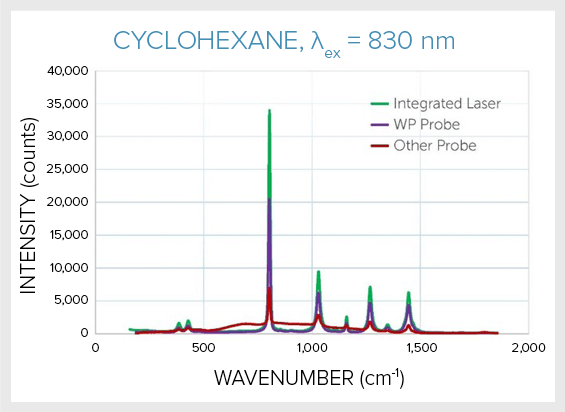

Using the WP 830 transmissive f/1.3 spectrometer design, the measurement of cyclohexane with 830 nm excitation yielded 10x more signals in the same measurement time than a traditional f/4 reflective CCT spectrometer, enabling small peaks to be easily observed and quantified. This is perfect when capturing brief phenomena, or for the detection of weak signals. With higher sensitivity, lower levels of laser power can be used, significantly reducing radiant exposure. This prevents damage to delicate samples and lowers the associated risk when identifying potentially explosive unknowns in the field.

Shorter Integration Times

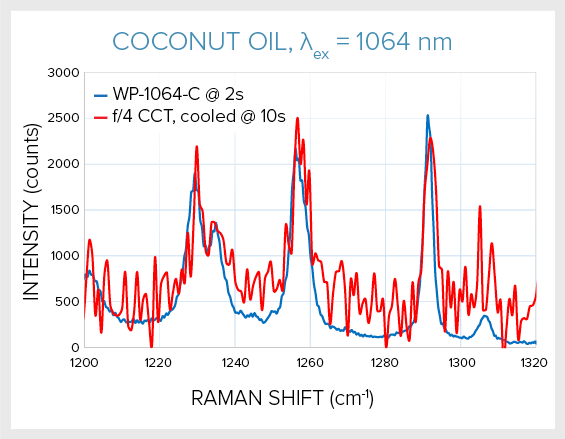

A traditional f/4 reflective CCT spectrometer needed 10 seconds to obtain a scan of coconut oil using 1064 nm excitation with quantifiable peaks. The WP 1064 transmissive f/1.3 spectrometer obtained an equal amount of signal with considerably less noise in just 2 seconds, enabling peak structure at 1220-1240 cm-1 to be resolved easily. Indeed, at this scan rate, averaging could be utilized to maximize SNR. Rapid measurements are optimal for high-throughput scanning in process and industry and also facilitating improved spatial resolution images to be obtained in the equivalent time during 2D mapping.

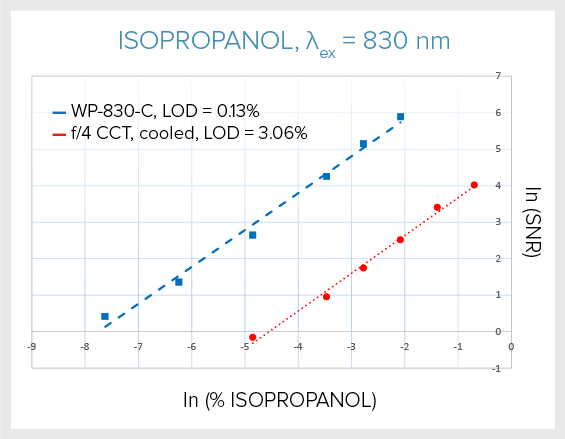

Lower Limit of Detection

While it is desirable to achieve higher sensitivity, it is ultimately the signal to noise ratio (SNR) that controls the lowest concentration of analyte that can be monitored – the limit of detection (LOD). During tests of isopropanol at 830 nm excitation, the WP 830 transmissive f/1.3 spectrometer exceeded the conventional f/4 reflective CCT spectrometer by >20x in LOD. This allows trace level detection of analytes in solution or on surfaces; analysis of new phenomena or complex mixtures can be conducted with ease. Lower LOD also facilitates more sensitive detection of taggants, and lower tag concentrations.

The Impact of Sample Coupling

Utilizing sampling accessories and optical fibers which are paired with the input aperture of the spectrometer is crucial when collecting the maximum amount of light from a sample. The use of an aperture-matched WP probe for Raman and routing fibers with 0.36 NA produces ~3x more signal when working with f/1.3 spectrometers than a typical 0.22 NA Raman probe.

The use of an integrated laser system improves signal by an extra ~80%, as it eradicates transmission losses and fiber coupling. Choose an integrated laser system for Raman for the best possible signal and minimum footprint,

Miniaturization – Reducing Size, Not Performance

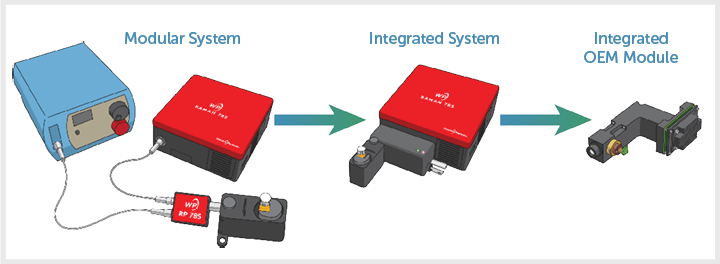

The more a spectroscopy system can be made smaller in size, the more places it can go. Modular systems are optimal for demonstrating a new concept and developing algorithms and spectral libraries for analysis, but they rarely rise to the challenge when it comes to industrial use. When modifying modular components for use in portable or OEM applications, it is favorable to minimize the number of components.

Fibers may be removed in favor of free-space coupling for increased durability and signal, active components are substituted in favor of more robust OEM models, and even the optical bench may be subject to change. The challenge then is to accomplish the same performance with the new components.

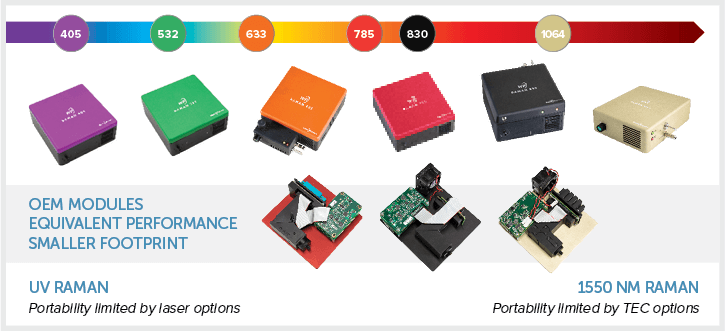

At Wasatch Photonics, the standard spectrometer line is built around a compact, sturdy OEM optical bench, enabling the same performance to be provided in a smaller footprint, at any volume. The example below demonstrates how the WP 785 Raman spectrometer (red) with a laser module (blue) and probe (black) can be integrated into a Raman system (center), and further downsized to produce an integrated OEM module with onboard laser, filters, and focusing optics. The same core optical bench is used throughout.

The advantage of this approach to product design is that proof of concept testing and initial research can be performed with modular components, to keep the system as flexible and reconfigurable as possible, and with the confidence that important factors like thermal stability, sensitivity, and unit-to-unit variability have already been addressed in the core spectrometer design and will remain consistent throughout the integration process.

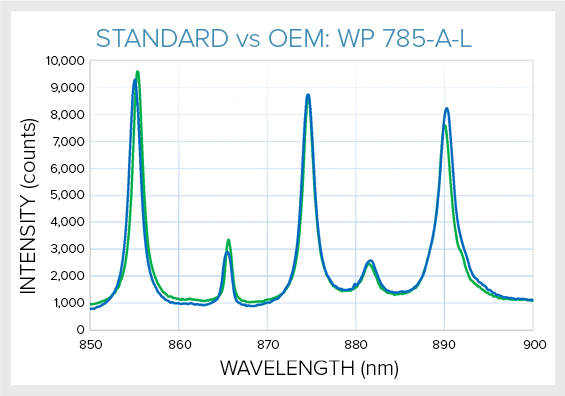

Standard Product vs OEM Module Performance

Given that the core optical bench remains the same at each stage of product development (integrated, modular, and OEM module), the performance does so too. This can be viewed in a comparison of 785 nm Raman measurements taken of cyclohexane at 50 ms integration time using a WP 785-A-L Raman system (785 nm integrated laser), in contrast to the equivalent OEM module. Please note, in addition to the spectrometer sensitivity remaining consistent, the instrument response function for the two models does so too.

The Importance of Thermal Stability

Thermal stability is of utmost importance in Raman spectroscopy, as it determines the requisite conditions for compensation or frequency of recalibration. It also affects the spectral reproducibility, which is key for high-precision library matching in a broad range of operating conditions.

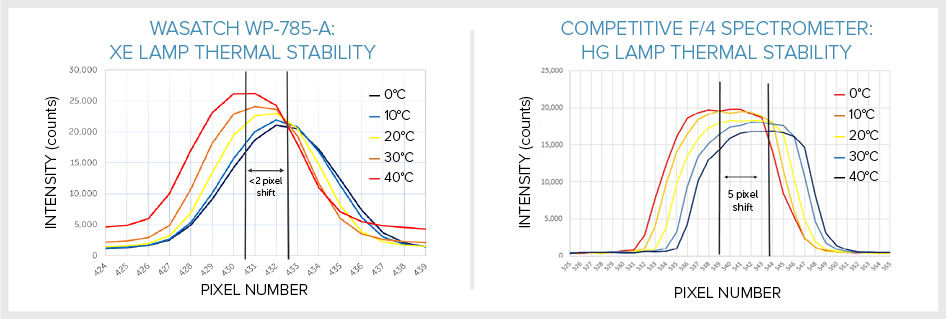

To verify the thermal performance of the Wasatch Photonics f/1.3 Raman spectrometer design, Xe emission spectra taken with a WP 785 ambient (uncooled) Raman spectrometer throughout temperature cycling was monitored, concluding that thermal shift is <2 pixels over 0-40°C. Likewise, similarly configuring an f/4 CCT spectrometer led to the experience of a much greater ~5-pixel shift over the same temperature range.

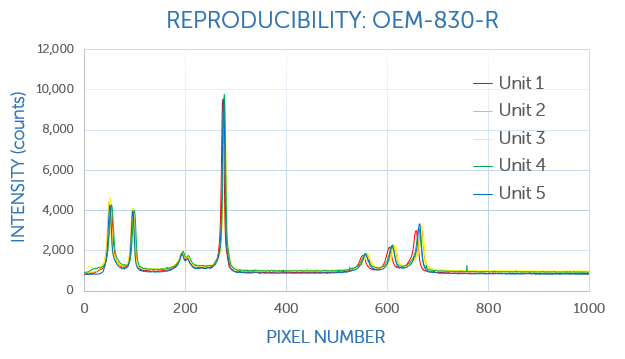

Unit-to-Unit Reproducibility

One really important aspect of spectrometer performance is reproducibility for OEM instrument manufacturers. Peak shape consistency between units is vital for building libraries in Raman. The transmissive f/1.3 spectrometer design and VPH grating have intrinsically less instrument response function variance from unit-to-unit in comparison to an f/4 reflective CCT spectrometer design. This enables Wasatch Photonics to provide sensitivity matching as part of their in-house QC for OEMs. The units shown in this article were intensity matched to <10% over the entire spectrum – at every single wavelength.

Wavelength – Extend the Choice, Extend the Science

First of all, establishing confidence in the spectrometer design’s sensitivity and volume producibility is the key factor closely followed by the selection of the right operating wavelength. In Raman spectroscopy, excitation wavelength influences signal level and background fluorescence.

Shorter wavelengths provide more signal, while longer wavelengths or near-UV excitation lead to decreases in background fluorescence for organic and biological samples. Cost-effectiveness also becomes an important factor, with many OEMs selecting 830 nm excitation over 1064 nm because of the relative cost of a silicon detector spectrometer vs one with an InGaAs array and TEC cooling. The source of excitation may also be a factor, both in relative cost and size, as well as availability and longevity (particularly for blue or UV lasers).

By providing access to 6 standard wavelengths for Raman – 405, 532, 633, 785, 830, and 1064 nm – and the option to further tailor wavelength for OEMs, Wasatch Photonics gives customers the tools for flexible design in order to produce the best system to meet the needs of your specific sample or application.

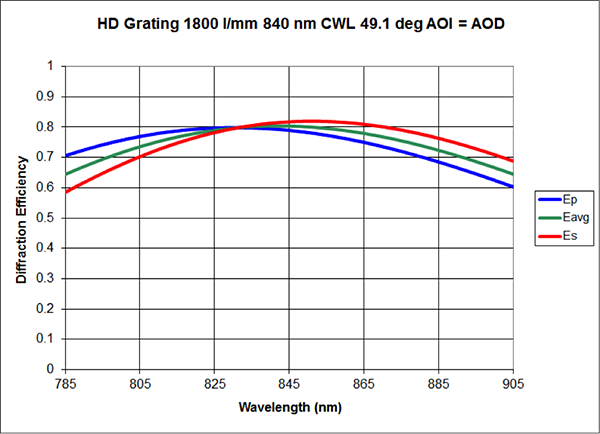

For clients requiring a different wavelength or bandwidth, as a manufacturer of volume phase holographic (VPH) gratings, Wasatch Photonics is uniquely positioned. The company can design and provide customized gratings completely tuned to OEM applications, irrespective of the excitation wavelength chosen.

Wasatch Photonics takes the time to better understand the needs of every single application, striking a balance relative to the needs for bandwidth and dispersion against efficiency using our multiple patented and proprietary grating technologies. The spectroscopy gratings increase efficiency and are ultra-low scatter, thus optimizing SNR.

Conclusion

Wasatch Photonics’ compact, transmissive f/1.3 spectrometer design provides an order of magnitude greater sensitivity and lower limit of detection than conventional reflective f/4 crossed Czerny-Turner spectrometers. The transmissive f/1.3 spectrometer design transitions easily from modular to reduced size footprints with no loss of performance as it is specifically designed for both research and OEM use.

Furthermore, it provides the thermal stability and unit-to-unit reproducibility that is crucial to state-of-the-art identification and quantification methods used for analysis in Raman spectroscopy. If you’re looking to go beyond the normal boundaries of Raman, this is most definitely an ideal place to start.

This information has been sourced, reviewed and adapted from materials provided by Wasatch Photonics, Inc.

For more information on this source, please visit Wasatch Photonics, Inc.