Over the last several years, laser vibrometry has secured a strong place in the automotive sector. This non-contact technique is utilized at Porsche Engineering to research and enhance the dynamic behavior of valvetrains throughout engine development.

Figure 1. A look at the valves of the test sample, mounted to the cylinder head mock-up. The laser vibrometer is in the foreground.

Figure 2. Pre-validation of a valvetrain layout on a single-valve test bench.

Figure 3. The reference and measurement laser beams of the vibrometer.

Valvetrain Design

An expertly tuned engine is required for optimum fuel consumption and high performance. At the foundation of these tunings, the valvetrain always has the possibility for improvement.

Heavy requirements are placed on these components, especially in the case of sports car engines, as they must provide the largest possible opening cross-section combined with short valve opening periods at a high rpm. For this reason, developers in this market are consistently aiming to enhance the properties of valvetrains.

A test bench (Figure 1) can be utilized in the initial stages of development to find out whether the valvetrain can definitely provide the characteristics detailed in a specification document, and if it will have the ability to resist the consequent demands placed on it.

The engineers at Porsche Engineering utilize special lasers to assess valvetrain dynamics, therefore there is no interference or physical contact. This enables the measurement of valve behavior at various speeds. The title image shows the reference and measurement beams, highlighted with smoke.

Measurements on the Test Bench

Simulating standard operation on a mock-up test bench, the cylinder head is pressurized with oil to take measurements (Figure 2). Expansion and oil temperature can be changed accordingly.

These parameters are determined and monitored in an electronic database. A high-performance electric asynchronous motor can be programmed to simulate real life operation and controls the whole timing assembly.

The chain drive is reproduced entirely with all intermediate guides, gears, and tensioning rails, along with the chain tensioner. In this way, valvetrain dynamics can be evaluated with the inclusion of all the external reactions and influences, for example damping influence of the hydraulic chain tensioner, variable camshaft moments, and the chain drive polygon effect.

Prior to taking measurements, the laser beam is angled to strike the valve head in a perpendicular fashion. An additional laser beam is positioned as a reference beam, adjacent to the valve seat and parallel to the first beam. In Figure 3, both reference and measurement laser beams can be observed as they have been illuminated by smoke.

By using a reference, the relative movement between the two points can then be analyzed, thereby showing the isolated movement of the valve minus the effects of sprung mass. In this way, valve speed and valve lift can be recorded precisely.

Data Acquisition and Evaluation

Porsche Engineering utilizes a Polytec HSV-2002 High-Speed Vibrometer engineered with the measurement of Formula 1 engines in mind. It can measure speeds of up to 30 m/s along with displacements (strokes) of up to 160 mm.

The collected data is saved and recorded in a time-synchronous manner. The Rotec RAS system employed by Porsche Engineering can record analog signals at a sampling rate of 400 kHz and at a resolution of 16 bits. A resolution of 40 bits and speed signals up to a frequency of 1 MHz can be recorded.

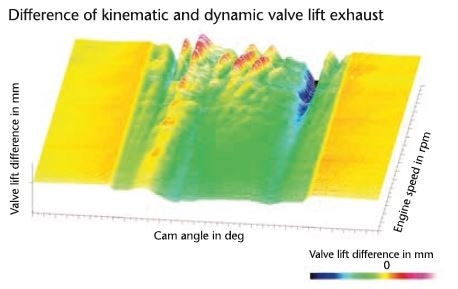

An integrated software package enables efficient analysis of the acquired data (Figure 4). The use of this system helps Porsche to analyze the effects of different spring stiffnesses, cam contours, valve drive masses, and spring progressions, for example.

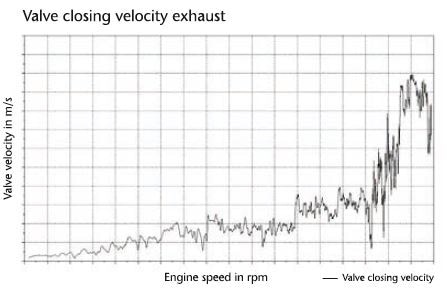

The effects of these modifications can then be evaluated through the examination of valve closure speeds (Figure 5) and valve accelerations, and by calculating Hertzian stresses and contact power processes. Furthermore, the evaluation of torsional vibrations can give additional information on operational behavior.

Due to the rise in more complicated valvetrains being produced with increasingly quicker development periods, valvetrain analysis is becoming more and more important.

Through the use of laser vibrometry at a beginning stage of development, Porsche Engineering is evaluating the valvetrain for dynamics, stress, and kinematic properties in the desired RPM range.

The required valvetrain development revisions were evaluated and targeted on multiple projects employing laser vibrometry, thereby avoiding expensive and time-intensive development loops.

Figure 4. Differences of kinematic and dynamic valve lift because of dynamic effects.

Figure 5. Increasing valve closing velocity with increasing engine speed.

This information has been sourced, reviewed and adapted from materials provided by Polytec.

For more information on this source, please visit Polytec.