The SiBrickScan (SBS) from Bruker is a dedicated at-line system for the FTIR quantification of interstitial Oxygen in complete Silicon ingots, resulting in a concentration profile along the longitudinal axis. Accessing this information without sawing wafers or test samples is considered to be one significant cost saving advantage.

Obtain Valuable Information to Verify and Optimize Product Quality

The Oxygen gradient of Si ingots enables important conclusions helping e.g. to identify batches of bad raw material or to monitor and optimize the Silicon crystallization process. Therefore, SBS will help to save costs by optimizing product quality and reducing the amount of defective wafers. Sample preparation efforts are greatly reduced by the random sampling of individual ingots. This sampling also provides appropriate information much earlier.

Highest Sensitivity by State-of-the-Art FTIR Spectroscopy

Interstitial Oxygen quantification by FTIR spectroscopy (ASTM/SEMI 1188) is a well-established and important analysis method, but limited to thin Si samples in the low mm range.

SBS overcomes this limitation, and is the first commercially available completely dedicated system to determine the Oxygen gradient in complete ingots along their major axis without the need of time-consuming and destructive thin sample preparation.

SBS efficiently uses a related infrared overtone absorption band combined with reliable and state-of-the-art Bruker FTIR technology.

Technical Details

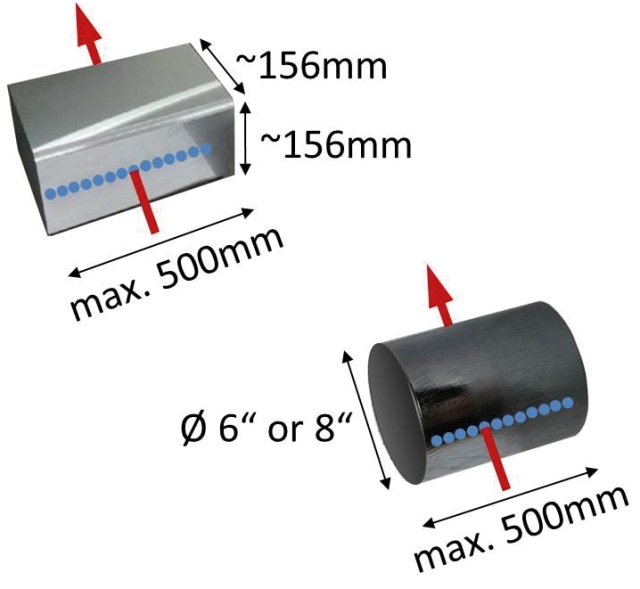

Dedicated SBS Versions for Different Ingot Types

SBS is available for mono or poly crystalline standard square PV ingots (cross section ~156 x 156 mm2) and also for cylindric Si ingots e.g. with ~150 mm (6") or ~200 mm (8") diameter.

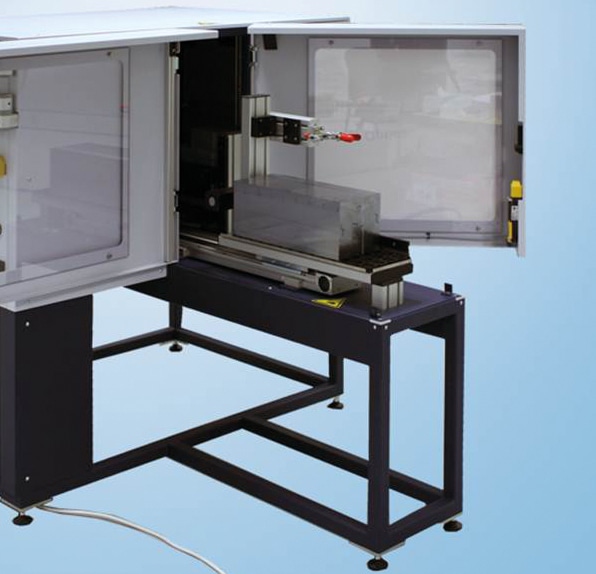

Industry Compatible and Robust Design

A precise and robust linear drive automatically controls the ingot measurement position: depending on ingot type and configuration, a spatial Oxygen resolution of ~12 mm can be achieved along the ingot axis. The risk of the operator coming into contact with moving parts is eliminated with safe and reliable interlock mechanisms.

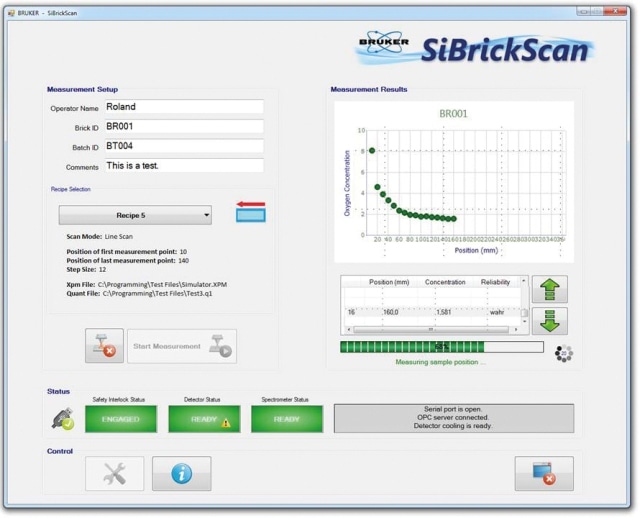

Intuitive and Easy to Use Software Interface

SBS is equipped with an intuitive and dedicated graphical user interface optimized for the industrial environment. The operation procedure can be learned within minutes by normal production workers: just load the ingot, select the desired analysis recipe, and begin the measurement. This is followed by automatically conducting the measurement, including data evaluation.

Innovative High Sensitivity Beam Path with Included Reference Sample

Highest measurement sensitivity is guaranteed by an innovative and unique infrared beam path. A high quality reference sample is already included in the instrument and the reference measurement is automatically performed.

Detector Options According to Customer Requirements

SBS is either available with a Stirling cooled detector, functioning independently from liquid Nitrogen. It is also possible to optionally order SBS with a liquid Nitrogen cooled detector, including an automatic refill device.

Applications

Quantification of Interstitial Oxygen Without Preparation of Thin Samples

The analysis of interstitial Oxygen in Silicon ingots up to 500 mm in length is allowed by the SBS. This vital information enables the qualification of individual ingots before sawing and the optimization of the crystallization process.

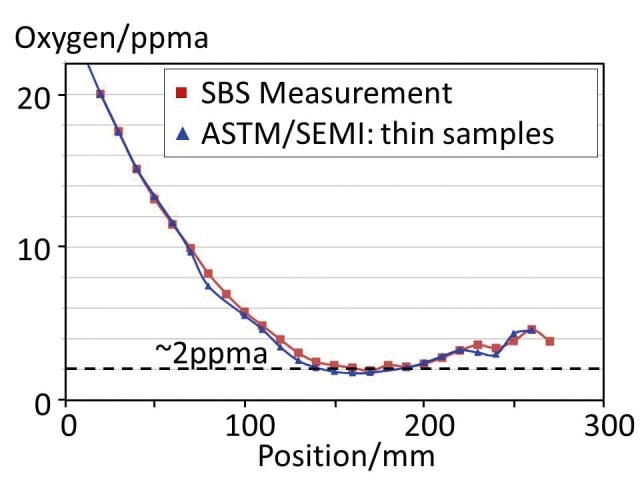

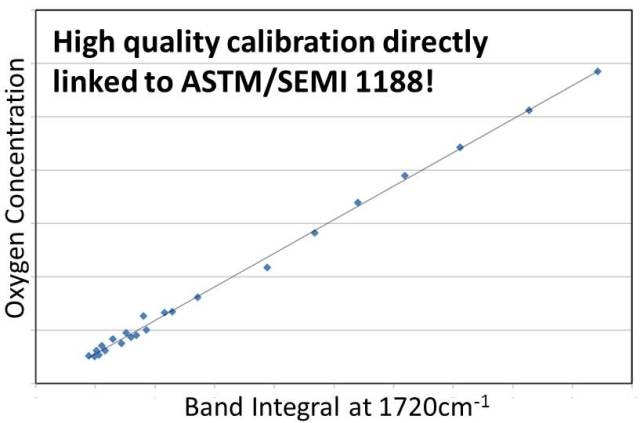

High Quality Calibration Directly Linked to ASTM/SEMI 1188

SBS Oxygen evaluation uses a calibration which is directly derived from/linked to ASTM/SEMI 1188. The interstitial Oxygen concentration is evaluated with highest accuracy as the correlation of both methods is almost perfect.

Highest Detection Sensitivity with SBS

SBS can obtain interstitial Oxygen detection limits < 2 ppma (< 1017/cm3) depending on sample properties (e.g. resistance) and shape.