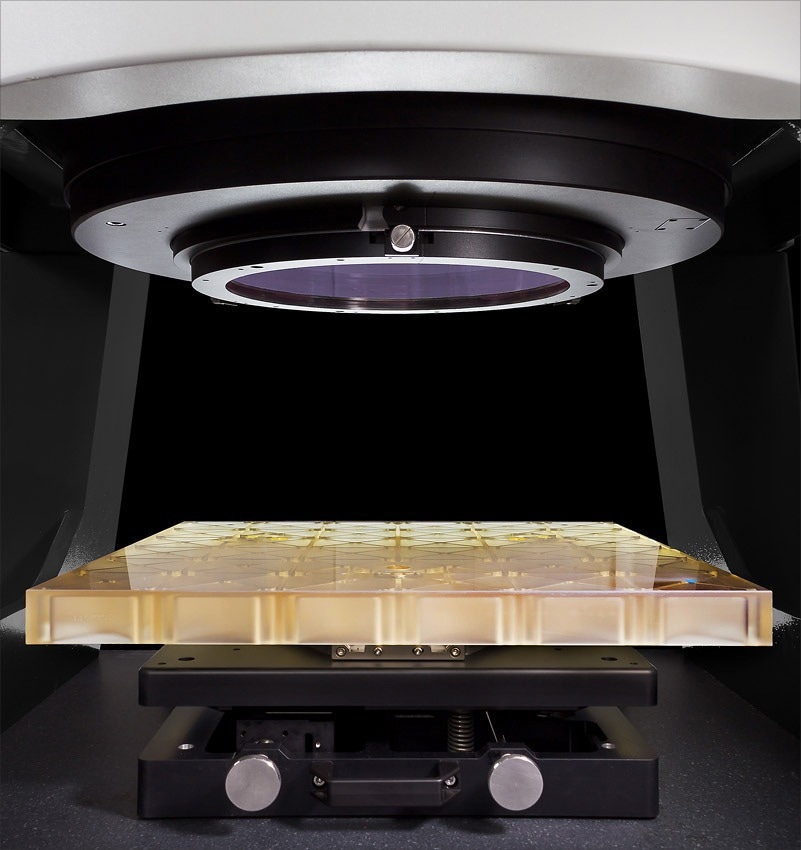

The Verifire XL is a complete interferometer workstation with a large aperture and a small footprint that makes it simple to test plano optics up to 300 mm in diameter.

With a powerful tip/tilt stage that allows reproducible part placement without the need for bespoke fixturing, this fully integrated system is simple to use.

The small footprint, which includes a controller monitor stand and built-in vibration isolation, uses the least amount of manufacturing floor space.

More Info

An independent large aperture workstation for measuring planar optical surfaces with a diameter of up to 12 inches (300 mm), such as mirrors, windows, semiconductor wafers, wafer chucks, and blocked flats.

Image Credit: Zygo Corporation

Key Features

- A 12” (300 mm) aperture with a downward-facing orientation makes handling and aligning parts simple

- Turnkey, complete system with 1/15th wave PVr transmission flat (TF), interferometer mainframe, passive vibration isolation system, and test part alignment stage

- A compact footprint reduces the need for costly floor space

- For accurate measurements in production environments, integrated vibration isolation and QPSI™ technology are used