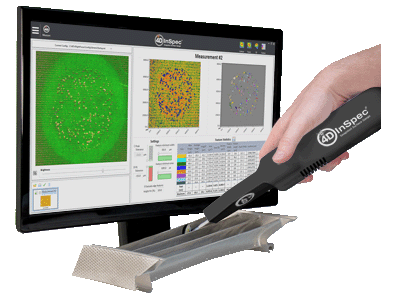

The 4D InSpec Surface Gauge from 4D Technology is a unique portable, precision instrument developed for non-contact surface defect measurement.

With affordability, portability, ease-of-use, and micrometer-level resolution, the 4D InSpec Surface Gauge puts high-resolution measurement where it is required — in the hands of inspectors in machine shops, on the factory floor, and in field service applications.

Image Credit: 4D Technology.

The 4D InSpec Surface Gauge rapidly measures defects like scratches, pits, bumps, dents, and nicks, as well as quantifies features like radii, break, dot peen depth, and rivet depth from 0.1 to 100 mils deep. It is much more precise and repeatable than that of visual comparison methods that are generally used for measuring surface defects.

Unlike high-end metrology systems, the 4D InSpec Surface Gauge is robust, affordable, and flexible for measuring a variety of part geometries in highly difficult environments.

The 4D InSpec Surface Gauge can be used to sample bulk surfaces directly on components or to access constricted corners. An optional fold mirror accessory allows the system to operate similar to a borescope to access features without line of sight.

Immunity to sensor movement and one-button operation render it easy to align and quantify, where a single cable tether and sturdy design endure the rigors of day-to-day use.

Image Credit: 4D Technology.

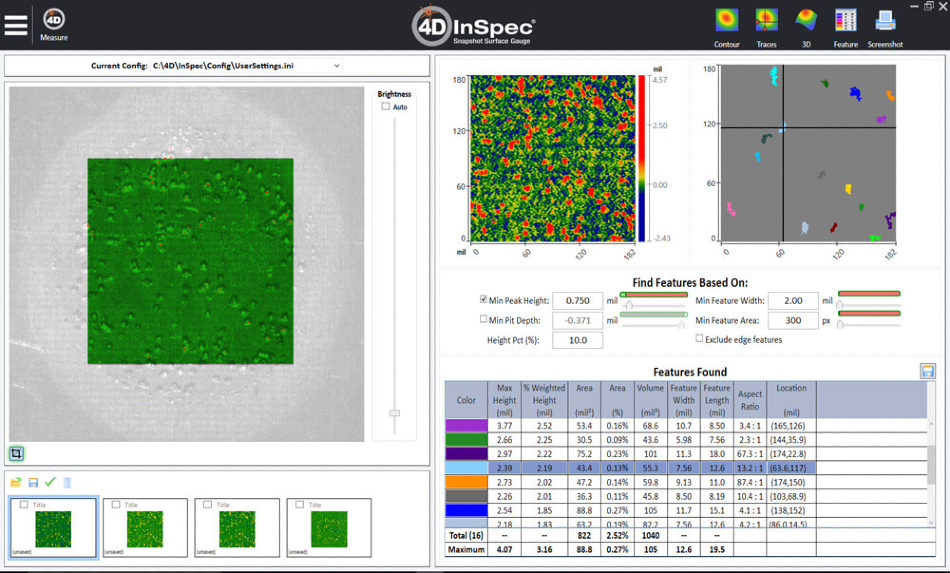

In a workstation configuration, the 4D InSpec Surface Gauge enables repeatable quality control data to be obtained easily and quickly. Setup, operation, analysis, and generation of reports are handled by a smart, touchscreen interface. Alternatively, the 4D InSpec Surface Gauge can be loaded on a robotic manipulator for complete, automated measurements of challenging components.

Image Credit: 4D Technology.

The integrated software with a smart touch-screen interface automatically identifies defects and computes their area, volume, height, location, and slopes. The operator can select from two-dimensional (2D) traces or three-dimensional (3D) plots to visualize defects in excellent detail. Moreover, the system allows data to be transferred easily to quality control systems through WiFi, USB, or LAN for quick pass-fail analysis. It creates a database of measurements made, to share over a network or to refer to for trending and historical review.

A comprehensive 4D InSpec system incorporates the instrument, a single Ethernet cable tether, a computer with HD 1080p touch-screen interface, a benchtop stand, and software. A range of accessories, such as a mobile workstation and Li-ion rechargeable battery with an operational time of up to 8 hours, is also available to enhance productivity and portability.

Image Credit: 4D Technolo