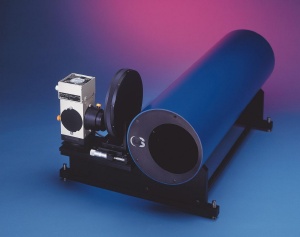

Optical Surfaces Ltd. has announced that it has delivered, to a leading European avionics / defence supplier, a 235mm clear aperture beam collimator enabling the company to precisely measure the quality of their Imaging systems from the visible to the IR using Modulation Transfer Function (MTF) criteria.

As the demand for higher quality, higher resolution optical systems for integration into sophisticated imaging systems has become more prevalent, many designers and scientists have chosen MTF measurement** as a flexible and accurate system characterisation tool. Beam collimators are optical assemblies that take divergent or convergent incoming light rays and produce parallel light output. They can be used to replicate a target at infinity without parallax. Beam collimators can be used to calibrate other optical devices, to check if all elements are aligned on the optical axis, to set elements at proper focus, or to align two or more devices. Beam Collimators are the optical system of choice for applications including MTF testing.

Dr Aris Kouris, Sales & Marketing Manager at Optical Surfaces Ltd. commented 'OSL was selected to produce the beam collimator due to our willingness to collaborate with the customer to produce an ideal system for their project'. He added 'Our heritage in supplying high performance off-axis reflecting beam collimators and beam expanders to customers around the world is unique'.

Optical Surfaces Ltd produced the required 235mm clear aperture beam collimator with an output wavefront error better than lambda/5 p-v and an off-axis optical design that produced no central obscuration and delivered highly efficient transmission.

Optical Surfaces Ltd has been producing optical components and systems for more than 45 years and is now accepted as one of Europe's leading manufacturers of high-precision optics for researchers around the world. The company's main workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions testing particularly with long path lengths become quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service. Optical Surfaces ISO 9001-2000 approved manufacturing facility provides the flexible resources to supply from single specialist requirements to OEM quantities. All high precision optics are provided with a complete quality test assurance report.

For further information on high performance beam collimators please contact Optical Surfaces Ltd.