Optical Surfaces Ltd has supplied two reflective beam collimators to a leading European supplier of high precision optics to military and defence contractors.

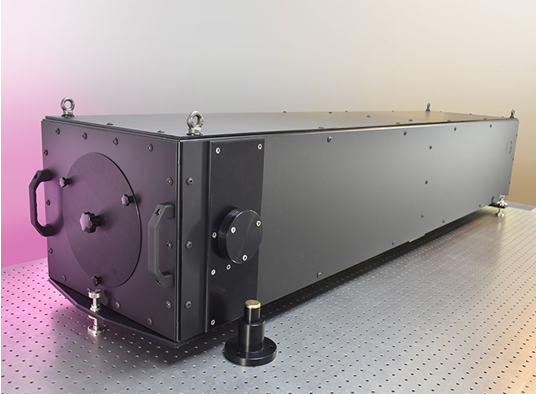

Reflective beam collimator for MTF testing of military optics. Image Credit: Optical Surfaces Ltd.

Reflective beam collimators are mirror assemblies that take divergent or convergent incoming light and produce parallel output. They can be used to replicate a target at infinity without parallax. Consequently, reflective beam collimators are the device of choice for performing Modulation Transfer Function (MTF) measurements over extended wavelength ranges.

Dr Aris Kouris, Sales Director of Optical Surfaces Ltd said “MTF is a technique, trusted by optical designers, for objectively evaluating the image-forming capability of military optical systems. We were chosen as a partner for this project because of our track record in supplying affordable, high performance beam collimators tailored to enable precise MTF testing of military optical systems”.

He added “The high stability and performance of our reflective beam collimators is achieved using a zero expansion off-axis parabolic mirror, manufactured to better than lambda/10 p-v surface accuracy. The all-reflecting design of our beam collimators is achromatic and with aluminium / magnesium fluoride coatings can operate from the UV to the infrared without adjustment. The optics within each beam collimator are secured using stress-free mounts and come pre-aligned for optimum performance. The off-axis design of our beam collimators produces no central obscuration thereby ensuring highly efficient transmission is obtained”.

Benefiting from a lightweight design and new assembly technique – Optical Surfaces beam collimators uniquely combine high stability, high performance, and short delivery time all at a market competitive price.

For further information on reflective beam collimators tailored to your application please visit https://optisurf.com/reflective-collimators/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / [email protected].

The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk. This provides an environment where temperature is naturally thermally stable, and vibration is extremely low. With such stable conditions testing of all beam collimators becomes quantifiable and dependable. In addition to these natural advantages, Optical Surfaces Ltd. has invested in an extensive range of test equipment and uses trusted methods to ensure accurate and reliable testing of surface accuracy, quality, and slope errors.