Optical Surfaces Ltd is a leading manufacturer of precision ellipsoidal mirrors for demanding applications in telescopes, beam expanders and high-resolution x-ray imaging instruments.

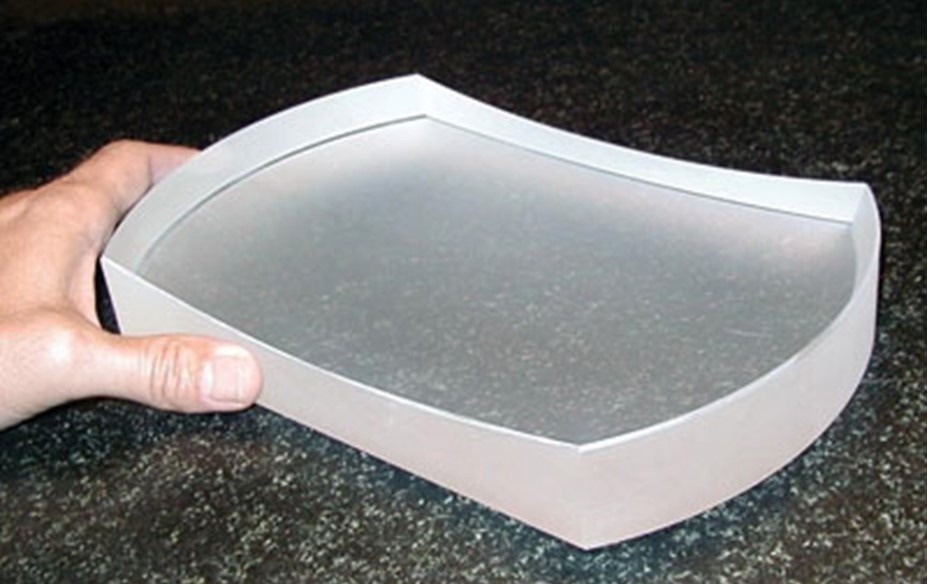

Large ellipsoidal mirror. Image Credit: Optical Surfaces Ltd.

Ellipsoidal mirrors are the optical component of choice in these applications as they efficiently refocus the light from one focal point to a second without the need for additional optical components thus allowing for a more compact optical system.

Optical Surfaces routinely produces ellipsoidal mirrors in a range of materials (Zerodur, BK7, fused silica) with typical surface accuracy of better than lambda/10 (dependent on size and radius) and surface quality of 20:10 scratch dig.

Dr Aris Kouris – sales director at Optical Surfaces commented “In addition to supplying batches of coated ellipsoidal mirrors to a leading instrument manufacturer we also produce one-off and prototype ellipsoids in a range of shapes (largest dimension up to 650mm) that offer high performance and excellent image quality”.

For further information on high precision ellipsoidal mirrors please visit https://www.optisurf.com/index.php/products/conic-sections/ellipsoids/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / [email protected].

Optical Surfaces Ltd has been producing demanding optical components, optical systems, and mounts for more than 60 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk. This provides an environment where temperature is naturally thermally stable, and vibration is extremely low. With such stable conditions testing of high precision optical components and mounted mirrors becomes quantifiable and dependable. In addition to these natural advantages, Optical Surfaces has invested in an extensive range of test equipment and have developed methods to ensure accurate and reliable testing.