Optical Surfaces Ltd. has collaborated with the Institute of Plasma Physics & Lasers at the Hellenic Mediterranean University (Rethymno, Crete, Greece) to develop high quality customised optics, including off-axis parabolic mirrors, as key focusing elements for their ‘Zeus’ 45 TW ultrashort laser pulse system.

The Institute of Plasma Physics & Lasers (IPPL) is internationally renowned for its cutting-edge research in areas including laser matter / plasma interactions, pulsed power generated plasmas and modelling / simulation of these problems. IPPL is one of the access points of the National Research Infrastructure - HELLAS-CH.

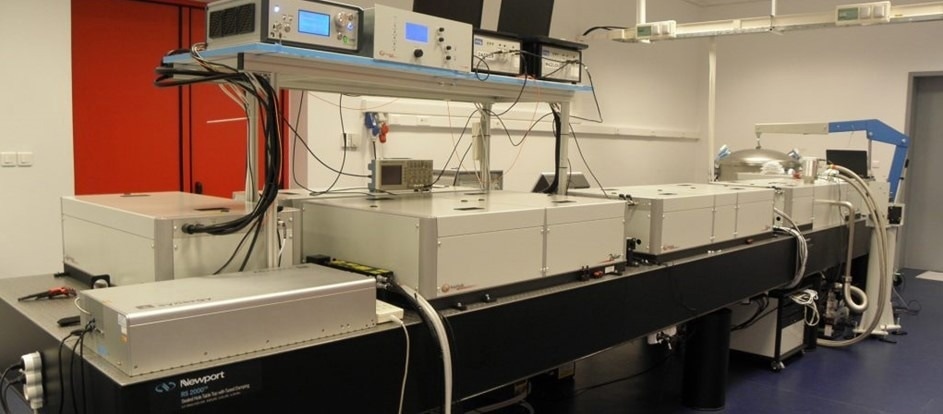

Zeus - the most powerful pulsed laser system in Greece (courtesy: IPPL)

Director of the IPPL Lab – Professor Michael Tatarakis said “The two new 76.14 mm diameter, 1008.7 mm focal length, hard dielectric coated mirrors are to replace damaged mirrors that Optical Surfaces made for us back in 2015. The damage is due to the natural impact of repeated highly energetic pulses (1018-1020 W/cm²) and the inevitable coating deterioration after extended high repetition rate use under such conditions. In cutting edge research, it is important to trust and collaborate with suppliers that have a good understanding of our research needs and can translate this into reliably producing optics that meet the high-quality demands of high energy applications. Certainly, reliable diffraction-limited optics such as those Optical Surfaces manufactures help us extend the frontiers of our fundamental research.”

Professor Tatarakis added “The intended application for these two new off-axis parabolic mirrors will be to explore new regimes in high repetition rate accelerated electron and ion beams with high stability via the interaction of the Zeus laser pulses with plasmas using gaseous targets”.

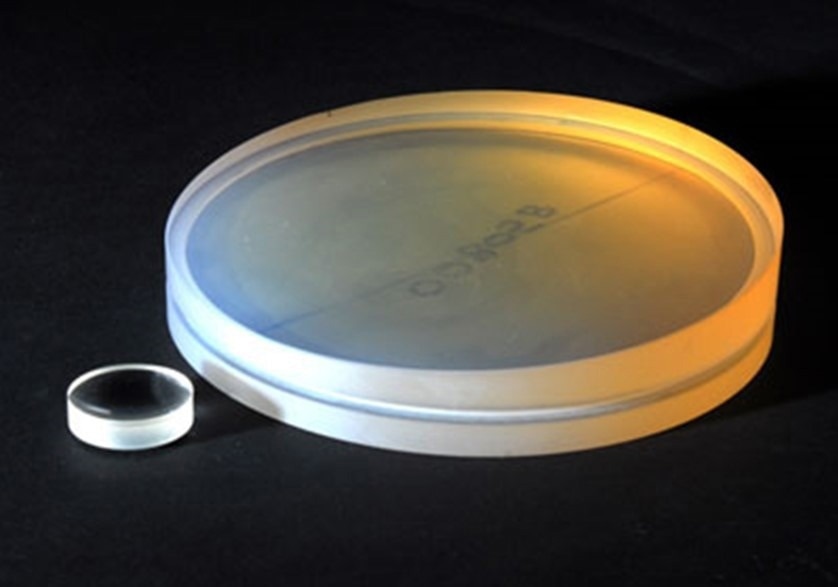

Benefiting from a highly skilled team of engineers and craftsmen, and a uniquely stable manufacturing environment, over the last 60 years - Optical Surfaces has established itself as a world leading producer of high precision off-axis parabolic mirrors. The company can routinely produce OAP mirrors with surface accuracy to lambda/20 (peak-to-valley) depending upon off-axis angles. Using proprietary polishing techniques Optical Surfaces can, depending on the surface accuracy required, achieve the natural limit to the off-axis angle of around 25-30 degrees and surface micro-roughness of less than 1 nm. A range of coatings is available for standard and custom components from metallic with or without protective overcoat to multilayer dielectrics and ultra-hard coatings.

A selection of high precision off-axis parabolic mirrors (courtesy: Optical Surfaces Ltd.)

Unlike standard parabolic mirrors, off-axis parabolic mirrors direct and focus incident collimated light at a specific angle, allowing unrestricted access to the focal point as well as reducing the size and minimising the weight of an optical design.

To learn more about the research interests and facilities at the Institute of Plasma Physics & Lasers please visit https://ippl.hmu.gr/en/home-en/.

For further information on high precision off-axis parabolic mirrors please visit https://www.optisurf.com/index.php/products/off-axis-paraboloids/ or contact Optical Surfaces Ltd on +44-208-668-6126 / [email protected].

Optical Surfaces’ ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk. This provides an environment where temperature is naturally thermally stable, and vibration is extremely low. With such stable conditions testing of high precision optical components and mounted mirrors becomes quantifiable and dependable. In addition to these natural advantages, Optical Surfaces has invested in an extensive range of test equipment and have developed methods to ensure accurate and reliable testing.