Optical Surfaces Ltd has launched a new mounting system that provides a highly stable platform for wedged back off-axis parabolic mirrors.

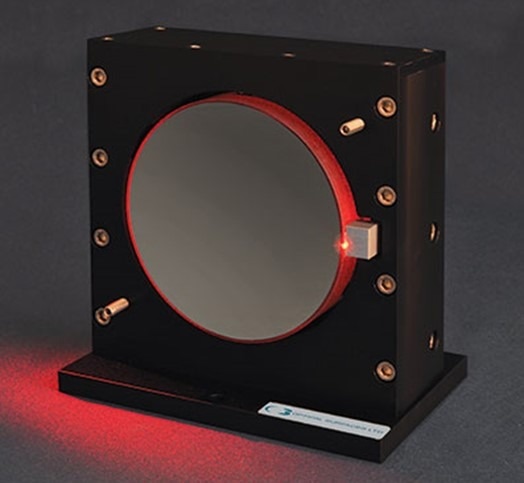

A wedged backed off-axis paraboloid in a tailored mirror mount. Image Credit: Optical Surfaces Ltd

A wedged backed off-axis paraboloid in a tailored mirror mount. Image Credit: Optical Surfaces Ltd

Off axis parabolic mirrors can be produced by two distinct methods, as a standalone single optic or from a parent on-axis paraboloid. Produced by the parent method, wedged back off-axis paraboloids can be very accurately centred. In addition, the back of the wedged back off-axis parabolic mirror can be polished and used to define the optical axis direction which assists alignment. Until now, mounting a wedged back off-axis parabolic mirror has been a difficult and time-consuming task.

Ultra-high precision off-axis parabolic mirrors are however useless unless they are positioned with absolute precision and are stress-free. Optical Surfaces Ltd has developed the expertise to produce stress-free mounts tailored for use with a specific wedged back off-axis parabolic mirror thereby optimizing the optical performance of these useful optical systems.

Constructed in black anodized aluminium – Optical Surfaces wedged back paraboloid mounts provide a secure and stable platform for mirror diameters from 50 mm to 200 mm. Angular alignment about two axes is made by means of dual action adjusters that allow high resolution positioning. The correct rotational adjustment is pre-set by the factory. Using these tailored optimised mounts, it is possible to align a wedged back off-axis parabolic mirror rapidly and accurately.

Benefiting from a uniquely stable manufacturing environment, and a highly skilled team of engineers and craftsmen, Optical Surfaces is today the world leading producer of high precision off-axis parabolic mirrors. The company can routinely produce off-axis parabolic mirrors with surface accuracy to lambda/20 (peak-to-valley) depending upon off-axis angles. Using proprietary polishing techniques Optical Surfaces can, depending on the surface accuracy required, achieve the natural limit to the off-axis angle of around 25-30 degrees and surface micro-roughness of less than 1 nm. A range of coatings is available for standard and custom components from metallic with or without protective overcoat to multilayer dielectrics and ultra-hard coatings.