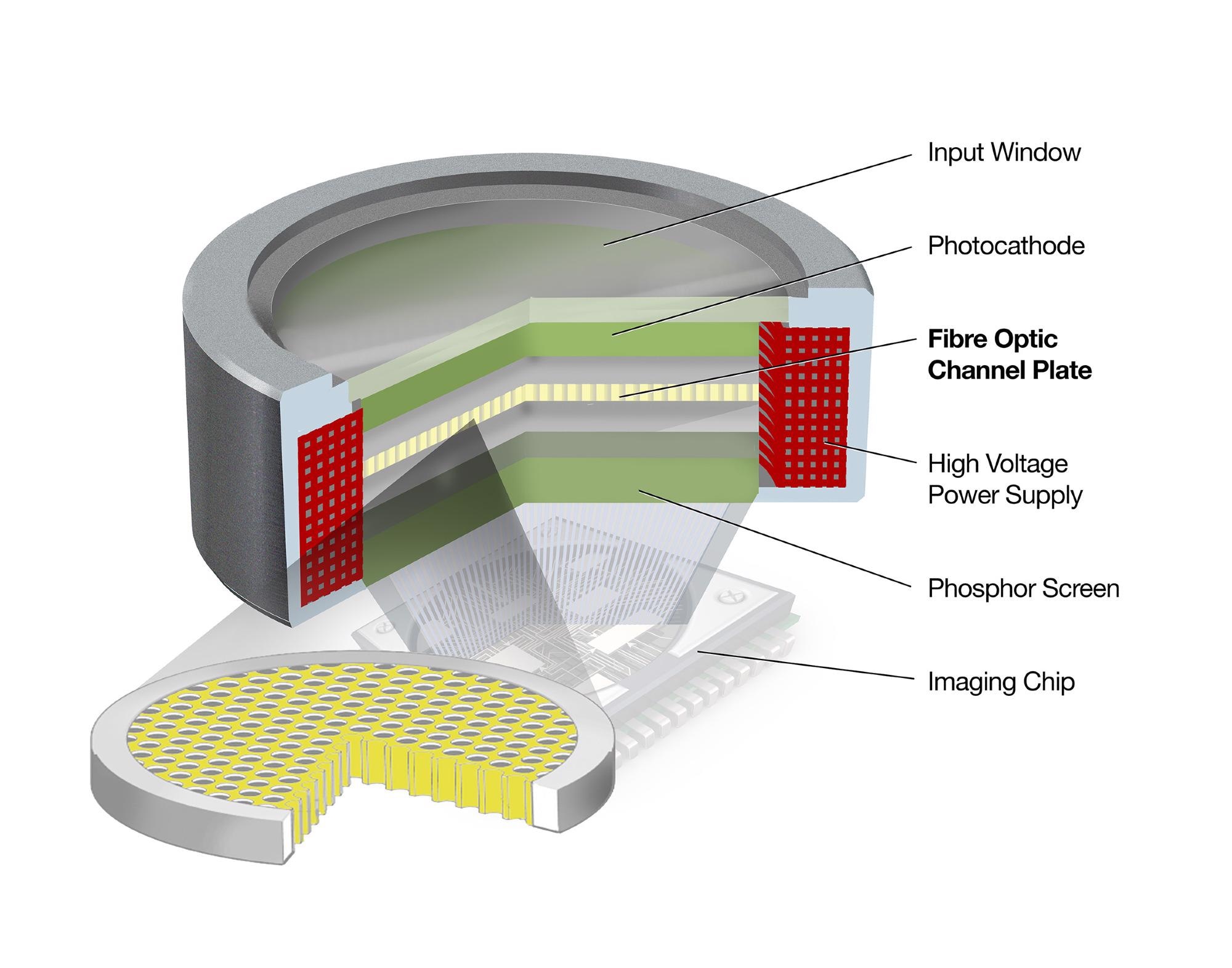

Optical Surfaces Ltd reports how it is machining and polishing high precision Fibre Optic Channel Plates (FOCP) for an X-ray shielding application.

Fibre Optic Channel Plates are widely used as optical devices to replace optical lenses because they require no focusing distance making them an ideal component when creating a compact optical device. Comprising a bundle of micron-sized optical fibres - FOCP are used as a lens to transmit light or an image with extremely high efficiency and low distortion. In each single fibre of a FOCP the light is transmitted by total internal reflection that occurs at the boundary between the core glass and the cladding glass due to the difference in their refractive index.

Fibre Optic Channel plates are widely used to couple light to solid state imaging devices such as CMOS and CCD image sensors. Used as the light receiving surface of an X-ray imaging device, the FOCP processed by Optical Surfaces Ltd is a key component preventing the image sensor in the camera from deteriorating due to exposure to X-rays.

To discuss your imaging application that may benefit from integration of a Fibre Optic Channel Plate please contact Optical Surfaces Ltd. on +44-208-668-6126 / [email protected].

Optical Surfaces Ltd has produced high precision optical components and systems for more than 50 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.