Optical Surfaces Ltd. has announced that it has delivered, to the Big Bear Solar Observatory (BBSO) located in Big Bear Lake, California, three high precision off-axis parabolic mirrors that will form key focusing components in the adaptive optical system associated with BBSO's new 1.6 metre solar telescope.

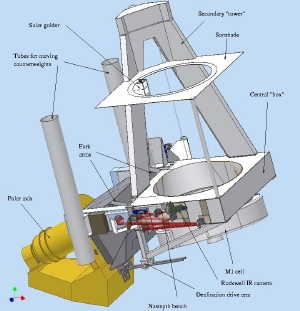

Due for completion later in 2008, the new 1.6 m aperture off-axis Gregorian solar telescope (http://www.bbso.njit.edu/) will be the world's largest telescope enabling precise studies of the physics of the Sun and observation of solar phenomena. The new BBSO solar telescope (NST) benefits from adaptive optics, which will allow atmospheric seeing to be corrected to the diffraction limit, an advanced computer systems capable of supporting sophisticated instruments such as Fabry-Perot interferometers and improved observation at infrared wavelengths. The adaptive optics will allow the BBSO NST to image actual photospheric flux tubes, at about 100 km resolution.

Commenting on their choice of supplier - Nicolas Gorceix (BBSO optical designer) stated ' Optical Surfaces Ltd. was selected to produce the critical focusing mirrors for the adaptive optics due to its technical excellence, reasonable pricing and a proven record in supplying ultra-smooth optics to leading astronomical research groups around the world.

Using proprietary production techniques, Optical Surfaces Ltd skilled craftsmen were able to produce the required three ultra-smooth 150mm diameter parabolic mirrors with a surface accuracy of lambda/10 p-v and excellent surface quality of 20:10 scratch / dig. All mirrors, effective focal length (2000mm), were given a protected silver coating offering peak performance from 0.39 - 1.6 microns.

Optical Surfaces Ltd has been producing optical components and systems for more than 45 years and is now accepted as one of Europe's leading manufacturers of high-precision optics for astronomical research. The company's main workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions testing particularly with long path lengths become quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.

Optical Surfaces ISO 9001-2000 approved manufacturing facility provides the flexible resources to supply from single specialist requirements to OEM quantities. All high precision optics is provided with a complete quality test assurance report.

For further information on ultra smooth off-axis mirrors for astronomical telescopes please contact Optical Surfaces Ltd. by telephone on +44-208-668-6126 or email [email protected]