In the midst of the battle to curb the spread of the coronavirus, a Santa Rosa company is playing a small role to tackle the pandemic that has upended life in Sonoma County and across the country.

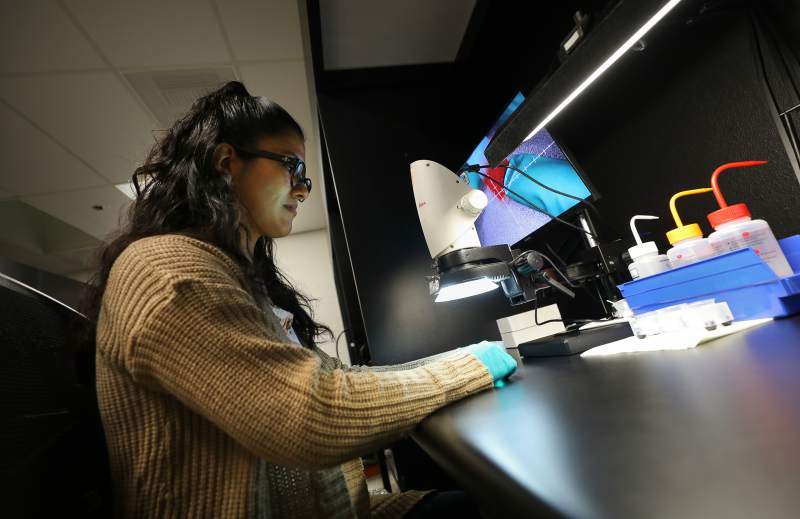

Marisela Zuniga performs final inspection of thin film optics at Alluxa, in Santa Rosa on Thursday, March 19, 2020. (Christopher Chung/ The Press Democrat)

Marisela Zuniga performs final inspection of thin film optics at Alluxa, in Santa Rosa on Thursday, March 19, 2020. (Christopher Chung/ The Press Democrat)

Most residents here and even business leaders never heard of Alluxa Inc., which operates in a nondescript office park near Charles M. Schulz–Sonoma County Airport. It’s a small company among a smattering of high-tech firms. The best known among them large corporations Medtronic and Keysight Technologies.

Under the radar, Alluxa has grown to 80 employees and now finds itself poised for an uptick as it produces a key part used in testing for COVID-19. The company, founded in 2007, makes optical filters and thin film coatings for a whole range of devices. One of those is the lab components that conduct a type of test called a polymerase chain reaction, known by its acronym PCR. That is the test in which swabs are taken from a patient and analyzed as part of a person’s DNA. As part of the process, the optical filters made by Alluxa help scientists zoom in through fluorescent detection to determine if the coronavirus is present.

“We are way down in the food chain, but it is indispensable to making the decision,” said Mike Scobey, the CEO who started the private company.

While the doctors, nurses and scientists are commended for their tireless work contending with this unprecedented public health emergency, there are many enterpreneurs and research laboratories working behind the scenes — and along the supply chain — who also play crucial roles. Another local company, Petaluma-based Labcon, makes test tubes to handle the swab samples for tests.

“We are kind of Rosie the Riveter making the equipment to fight against the virus,” said Shaun McCaffery, a mechanical engineer who works as a contractor for Alluxa and also serves as a Healdsburg city councilman.

The company designs and builds its own machines that produce the filters — which can be as small as a few millimeters for handheld systems.

Alluxa has prioritized its work in the life sciences sector, Scobey said. The testing components it makes are then assembled at other plants by large health sciences firms, which are then sold to medical and testing labs. There are now about 20 county and state labs in California performing virus testing of patient samples, according to the California Department of Public Health.

During the global coronavirus pandemic, innovation and testing activity have sped up on testing and vaccines. Roche, the big Swiss pharmaceutical maker, has received regulatory approval for advanced polymerase chain reaction testing. This technology has been around for decades, but scientists are constantly improving it with the development of new devices that are faster and more accurate. That triggers the need for new component parts from Alluxa and other tech firms.

“We compete on a global stage. About 40% of our business is overseas,” Scobey said. “We have to compete against the world. You have to offer the best performance at a reasonable cost.”

The Santa Rosa company is targeting sales of $50 million in the near future, he said. Alluxa’s investors are not venture capital firms, but strategic partners, who are also typically customers, and therefore not looking to make a quick buck, Scobey said.

The CEO saw the promise of the optical filters earlier in his career when he worked at Optical Coating Laboratory Inc., a local tech pioneer that spawned employees who also launched their own ventures. Also, Alluxa has attracted employees who have previously worked in the telecommunications field, since it does work in that sector, as well as robotics, semiconductors and the defense industries.

One area where it is used is in the research of driverless cars. Its filters help detect the laser light the system uses to map the three-dimensional area around the car.

“The world’s changing, so you have to stay on top of it with the new demands. If you are complacent, and if you don’t continually reinvent yourself, you can’t grow and you can’t take advantage of the opportunities,” Scobey said.