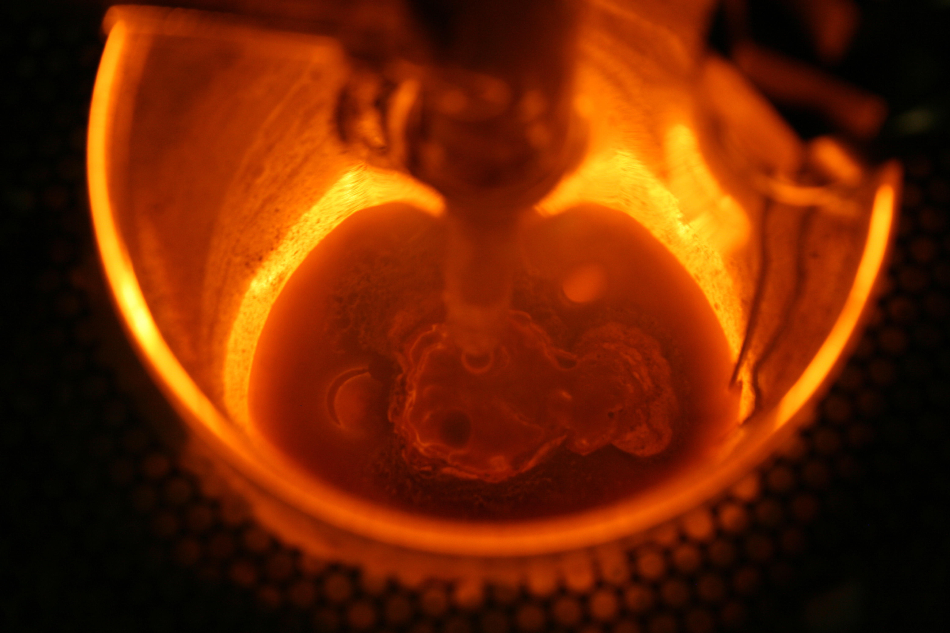

Resolve Optics has developed and supplied an Infrared (IR) endoscope to enable safe monitoring of the glass vitrification process within a radioactive waste processing plant using a thermal camera.

The processing plant required a method of monitoring the temperature of their waste material to ensure that there was not an excessive build up of heat that could lead to fire. With the level of radiation around the vitrification process unsafe for operators and also likely to rapidly destroy the thermal camera a remote measurement solution was sought.

Operating at 7-14 microns, the prime function of the IR endoscope was to provide the desired field of view to monitor the vitrification cell and to transfer the image to the bolometer based thermal camera. For added safety the thermal camera was mounted after a 90° fold to ensure it was not in the shine path of the radiation.

Due to the large aperture and sensitivity of the bolometer-based camera the endoscope required carefully positioned baffles to ensure there were no stray light reflection that could degrade the performance of the camera leading to imprecise monitoring of the vitrification process.

The IR endoscope system designed and developed by Resolve Optics is capable of helping thermal cameras safely monitor glass vitrification radioactive reprocessing.

For further information on bespoke optical systems able to withstand challenging operating environments (radiation, temperature, pressure or vibration) please contact Resolve Optics on +44-1494-777100 / [email protected].

Drawing upon approaching 30 years experience - Resolve Opticshas built a strong reputation for specialist lens design and manufacture of smaller production quantities of radiation-resistant (non browning) lenses and optical products on time to strict quality and target price guidelines.