Optical Surfaces Ltd. is a leading producer of high precision mirrors for Schlieren imaging applications involving airflow turbulence, explosive shockwaves, gas leaks and visualisation of transparent thermal phenomena.

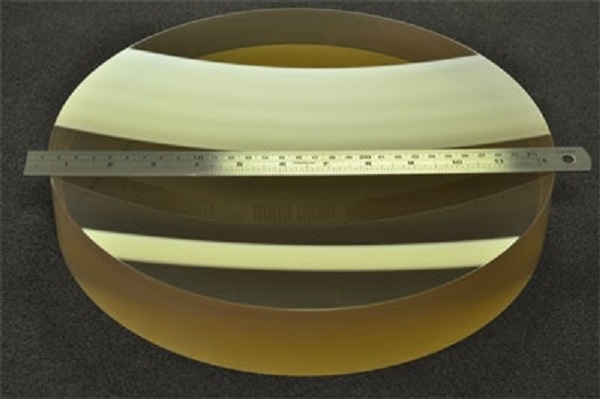

Drawing upon its uniquely stable manufacturing environment - Optical Surfaces is able to routinely produce the highest quality concave spherical mirrors (up to 800mm in diameter) for Schlieren imaging systems in a range of materials including Pyrex, Zerodur and ULE.

Optical Surfaces’ optical craftsmen routinely produce spherical mirrors with surface accuracy of better than lambda/10 with particular emphasis on smoothness of the profile. Final characterisation of surface smoothness using highly accurate interferometric measurements. Ultra high precision surface finish and durable optical coatings combine to provide superior Schlieren image quality.

Schlieren imaging is a widely-accepted method for visualising density variations in transparent media. In one of the most common types of Schlieren imaging system a source directs light onto a spherical mirror, which collimates the light and redirects it onto a second identical mirror. The resultant image may be captured by an imaging camera or on a screen.

For further information on ultra-high precision concave spherical mirrors for Schlieren imaging please visit http://www.optisurf.com/index.php/products/spherical-mirrors/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / [email protected].

Optical Surfaces Ltd. has been producing optical components, reference flats and beam expanders for more than 50 years and is now accepted as one of the world’s leading suppliers for high power laser research. The company’s ISO 9001-2008 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions, testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.