Optical Surfaces Ltd. is a manufacturer and supplier of high precision, custom beamsplitters and beamsplitting assemblies to leading spectroscopy, interferometry and imaging companies worldwide looking to enhance the performance of their instruments.

In optical systems, beamsplitters play a key role in dividing, recombining, and managing the directions of multiple beam paths. Using beamsplitters - light may be divided into separate wavelengths and / or polarization states. In addition beamsplitters can split light to provide specific values of transmittance and reflectance.

Drawing upon a uniquely stable production environment and a highly skilled workforce -Optical Surfaces is able to manufacture custom beamsplitters that offer higher flatness and parallel specifications than is routinely available. Typically OSL beamsplitters are manufactured to a surface accuracy of lambda/20 p-v at 633nm, a surface quality of 10/5 and microroughness of less than 1.2nm rms. Supplied mounted or unmounted, custom beamsplitters from Optical Surfaces can be supplied with an extensive range of coatings designed to operate at your required angle of incidence.

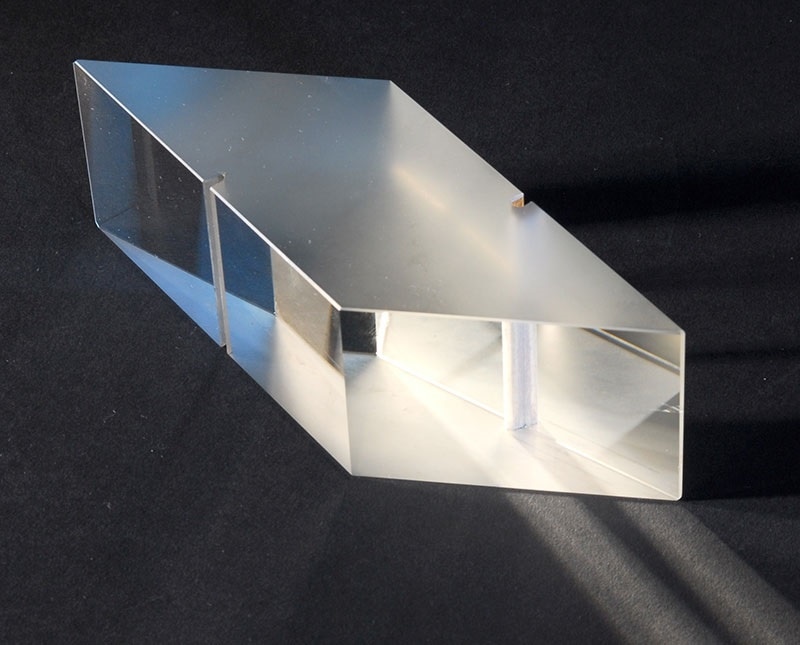

Optical Surfaces has experience and expertise in producing a wide variety of custom beamsplitters. This includes plate, wedge, cube, periscope, penta prism and custom shaped beamsplitters. In addition, Optical Surfaces has also produced dichroic, multi-wavelength, polarising and laser insertion beamsplitter prisms.

For further information please visit www.optisurf.com/index.php/products/prisms-beamsplitters-filters-and-fibres/ or contact Optical Surfaces Ltd on +44-208-668-6126 / [email protected].

Optical Surfaces Ltd. has been producing optical components and beam expanders for more than 50 years and is now accepted as one of the world’s leading suppliers for high power laser research. The company’s ISO 9001-2008 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions, testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.