Optical Surfaces Ltd. has received an order from Tesat-Spacecom GmbH & Co. KG. for a high performance, thermally stabilised beam expander. The beam expander will be used as part of the Tesat Optical System Test Bed for verification of the optical performance of their Laser Communication Terminals (LCTs).

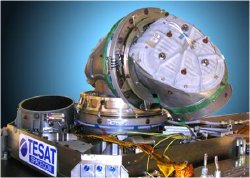

Tesat-Spacecom, based in Backnang, Germany, is a leading global designer and manufacturer of payload equipment for communication satellites. Tesat LCTs are the result of more than two decades of development expertise in the field of optical communications, and Tesat's broad knowledge of space systems production. The U.S. Missile Defence Agency's NFIRE satellite, built by General Dynamics, and Germany's TerraSAR-X satellite both launched in mid 2007 each carry a Tesat LCT. This equipment enables point-to-point data transfers with high data volume. With a range of 45,000 km and a transfer rate of more than 5 Gigabit per second, this technology is revolutionary and communication via laser allows a 10-times higher data rate, compared to a usual microwave link.

Reflecting on their choice of supplier, Dr. Andreas Weichert, responsible for the Tesat Optical System Test Bed, commented: 'Optical Surfaces Ltd was selected to produce the critical 10x Beam expander for our Optical System Test Bed because of their impressive track record in preparing high performance optical systems for telescope and space projects'. He added 'We were also very pleased with a previous beam expander supplied by Optical Surfaces Ltd in 2006'.

Using proprietary production techniques, Optical Surfaces' skilled craftsmen will produce two concave off-axis parabolic mirrors, with a combined wavefront accuracy of lambda/35 rms, that form the principal optical elements of the common focus 10x Beam expander. The excellent surface accuracy achieved during manufacturing will enable the Beam expander to provide sustained high optical performance over the complete field of view (+/- 0.1 degrees at large aperture). Manufactured in INVAR - the Beam Expander was designed be used in vacuum at 10-6 mbar and offers high thermal stability for thermal gradients that may be as much as 10°C along the length of the instrument.

Optical Surfaces Ltd has been producing optical components and systems for more than 45 years and is now accepted as one of Europe's leading manufacturers of high-precision optics for satellite deployment and astronomical research. The company's ISO 9001-2000 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.