In today's competitive environment, industrial manufacturers recognize that delivering exceptional products is no longer enough. Every organization is now striving to find ways to shorten its development cycles to maintain a competitive edge over its rivals.

While many manufacturers prefer to handle most of their product development internally, this may not be the most effective approach to producing optical devices.

Before deciding, it is essential to thoroughly assess whether manufacturing optical parts and components in-house or outsourcing them is the best strategy for the team, budget, and business goals.

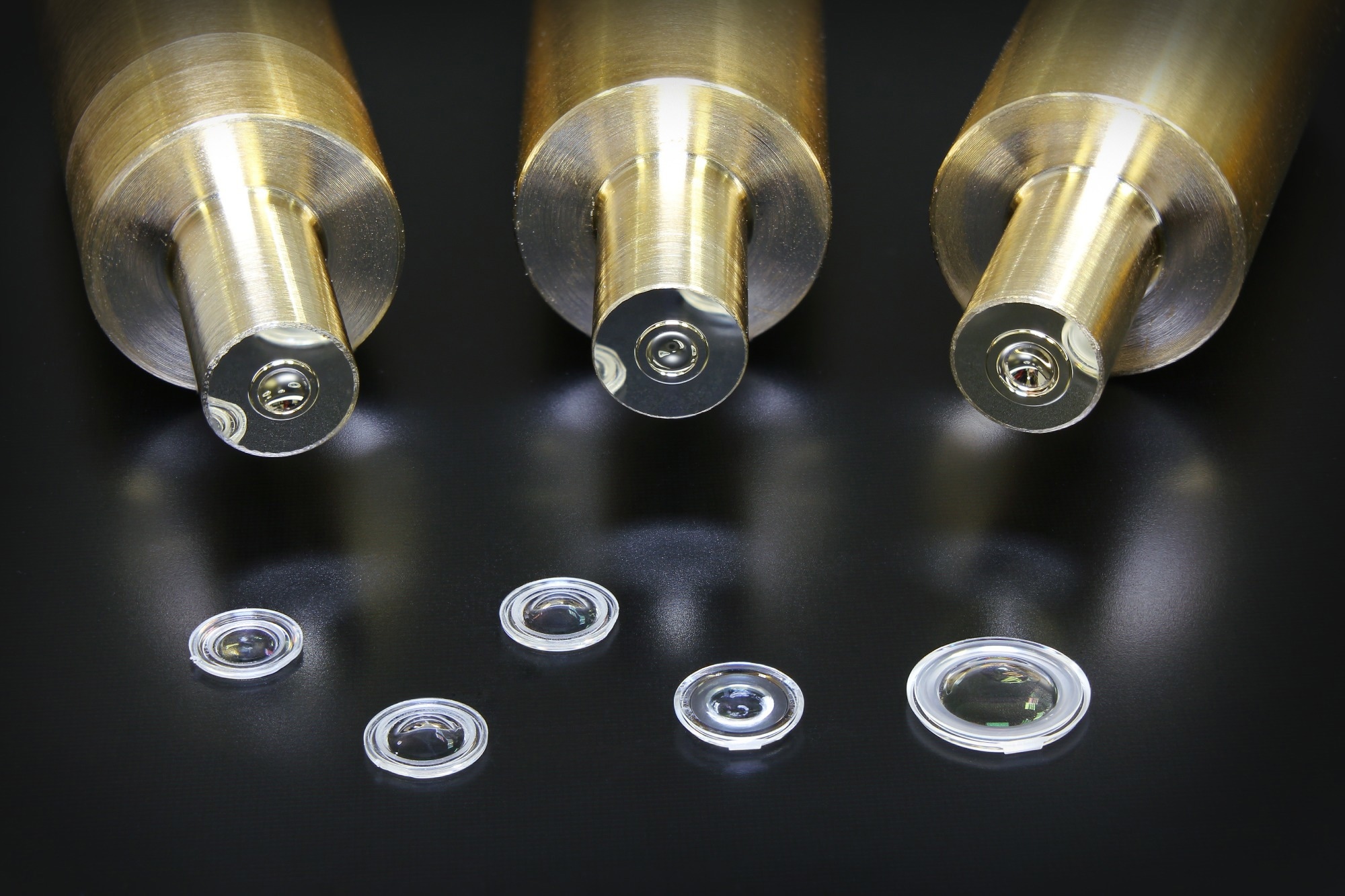

Image Credit: Zygo Corporation

Considerations for In-House Optics Manufacturing

When considering in-house optics fabrication and assembly, it offers greater control over the product development process but can be expensive and time-consuming. Finding personnel with the necessary expertise in this specialized field can be challenging, and acquiring the required equipment alone can take months.

Developing the expertise to master the intricate processes involved in optics fabrication can take years. Unless the projected production volume is high, the cost savings from internally produced optics may not outweigh the fixed costs associated with implementing and maintaining the infrastructure.

The infrastructure needed for optics fabrication and assembly is highly specialized and not readily adaptable for other purposes. Precision is vital in optics manufacturing, with tolerances measured in microns and nanometers.

Achieving such precision requires a unique skill set and expertise that is uncommon found in traditional machine shops. Moreover, working with brittle and delicate materials necessitates meticulous handling to prevent expensive fractures or cosmetic defects.

In the realm of optical devices, the field involves the physics of light, which can make the mathematical aspects complex, leading to counterintuitive conclusions.

Considerations for Outsourcing Optics Manufacturing

In contrast, certain factors come into play when opting to purchase optics from established vendors.

These factors include avoiding the margins added by optics vendors, having a long-term demand for high volumes of optics, concerns about losing control over production schedules when outsourcing, or the need to retain intellectual property within the company.

While there are cases where the substantial upfront investment required for in-house production may pay off, in most scenarios, the advantages of purchasing from a reputable vendor outweigh the benefits of internal production.

Choosing to buy optics from a vendor eliminates the need for significant upfront investments in infrastructure, equipment, and personnel.

This is particularly beneficial when the future demand and volume for optics are uncertain. Outsourcing also provides predictable and well-defined costs, with vendors taking responsibility for any overruns.

Even when the demand is for low volumes, vendors specializing in high-volume production across multiple products can leverage their efficiency to offer cost-effective solutions.

Continuous technological advancements in optics fabrication and metrology also lead to the rapid depreciation of investments, making purchasing optics from vendors who consistently invest in improving their tools a more appealing proposition.

From a scheduling perspective, buying optics from vendors also brings advantages. Outsourcing to specialists with extensive experience in the field reduces time to market as there is no need to overcome a steep learning curve.

Vendors' expertise enables efficient product design and development, minimizing costly errors and expediting the process, particularly in cases with high design complexity.

Collaborating with vendors who already possess the necessary equipment and experienced teams saves significant time compared to building the required optics and manufacturing infrastructure from scratch.

Outsourcing optics manufacturing is ideal, particularly when the purchased optical component is not a critical enabling technology for the customer's final product.

This approach allows resources and attention to be focused on other crucial areas of the business. Vendors become risk mitigators, as well as reliable and efficient partners that complement the efforts of internal teams dedicated to the core aspects of the business.

When to Engage an Optics Partner

When deciding to purchase optics, it is crucial to connect with a competent vendor at the appropriate stage of the product development process.

In the early stages of product development, it is important to prioritize agility, quick iterations, and cost-effectiveness. These aspects can be effectively managed by internal resources and dedicated consultants who do not carry the overhead costs associated with a production vendor.

During this phase, the focus is on accurately defining the technical specifications and determining the operational parameters through prototype testing. However, as the transition to the product implementation phase takes place, it is advisable to seek the services of a vendor such as Zygo.

This stage is characterized by the completion of the proof of concept, the finalization of the product concept, and a thorough understanding of the technical performance parameters.

At this point, the system-level specifications, including size, weight, power, and optical requirements (such as field of view, image or beam quality, numerical aperture, and radiometry), are clearly defined, and environmental requirements are established.

Collaborating with vendors such as Zygo during the product implementation phase allows for the creation of optimized designs that are specifically tailored to the intended purpose. These vendors can provide accurate specifications, predictable schedules for prototypes, and initial low-rate production.

Such vendors possess extensive expertise and knowledge gained from manufacturing similar devices, enabling faster fulfillment and minimizing errors and costs. Competent vendors have a well-established supply chain in place to accommodate product requirements.

Vendor Selection Questions

When selecting a vendor during the product implementation phase, there are several factors to take into account. It is important to seek vendors who develop their machinery for optics fabrication, assembly, and testing.

These vendors possess a deeper understanding of the product and can achieve compounding returns through continuous improvement.

It is also essential to assess the vendors’ track record in producing devices similar to the ones that are required, as this indicates their ability to deliver efficiently and adhere to schedules.

Lastly, it is advisable to choose a vendor that can leverage its existing infrastructure to manufacture the needed parts, reducing capital investment costs and ensuring more efficient and cost-effective production.

Partnership and Trust

The significance of partnering with a subcontracting specialist company for designing, developing, and manufacturing optical components cannot be understated.

While the term "partnership" is often used loosely, it does not always live up to expectations. Many supplier-customer relationships end up being mere transactions, lacking the genuine collaboration necessary for an efficient product development process. However, a well-functioning partnership can make a substantial difference.

Customers are sometimes cautious about entering into a partnership. There is a fear of being locked into a relationship once the project progresses from design and development to manufacturing.

Nonetheless, if a supplier demonstrates an open, honest, and trustworthy approach to the relationship and pricing, these concerns can be addressed.

A genuine partnership entails establishing clear expectations and maintaining open communication, finding the appropriate expertise for the specific application, and implementing robust program management and processes to stay on track.

Trust is the foundation of a successful supplier-customer relationship, offering obvious benefits. Conversely, the absence of trust can lead to wasted time and difficulties. A good relationship allows both parties to focus on the end goal rather than getting lost in contractual details designed to protect against every conceivable challenge.

When trust is lacking, the relationship often becomes transaction-oriented, with the customer retaining internal ownership of the design (without the necessary support skills) and viewing the supplier merely as a job shop, seeking to reduce dependency.

In such a relationship, there is no commitment or shared vision, and both sides constantly vie for advantage in future contract negotiations. Regarding trust, it can be beneficial to regard the chosen optical component supplier as a consulting business rather than just a manufacturing entity.

This mindset shifts the initial interactions toward discussions about working methods, expertise, and trust. If a supplier is approached solely as a manufacturing business, the focus immediately shifts to technical parameters, capabilities, and specifications, which can be challenging for customers to accurately assess.

Therefore, customers should consider two crucial questions:

- Can they trust that their partner will safeguard their interests even when they are not closely monitoring them? This aspect of trust pertains to values. Customers should be concerned about long-term interdependency due to the manufacturing relationship. Will the supplier be honest and transparent when they make mistakes? Will they promptly inform the customer of any issues that may arise before it becomes too late to take action?

- Second, can customers trust their partners to deliver exceptional results? This question revolves around competence. Does the partner possess the necessary skills, capabilities, and experience to provide the solutions they need? Can they guarantee that no matter how challenging the problems may be, they have a talented team capable of efficiently solving them? Will they create designs that align with the requirements without unnecessary expense or a high risk of failure in the field? Do they possess the requisite processes and discipline to meet established schedules?

Summary

Establishing a partnership based on trust and competence with the chosen optical component supplier is crucial for a successful collaboration.

Therefore, open communication, shared values, and the supplier's ability to deliver exceptional results should be prioritized. By doing so, the customers can establish a reliable and efficient relationship that propels their project forward.

This information has been sourced, reviewed and adapted from materials provided by Zygo Corporation.

For more information on this source, please visit Zygo Corporation.