When separating various wavelengths of light with high spectral resolution in a compact, efficient manner, diffraction grating is the answer to your specific requirements.

Diffraction gratings are optical components that are used extensively, and they feature periodic structures that facilitate the dispersion of light in a more compact, accessible format than a prism. They function based on the principle of interference to break multi-spectral light into its component wavelengths and, similar to a prism, disperse them spatially across a range of angles.

Image Credit: Wasatch Photonics, Inc.

The most frequently used type of grating structure utilizes a series of parallel rulings across a surface similar to a series of slits, provoking a superposition of waves that diffract light by wavelength, separating it into its constituent colors. This is not the only fundamental design type of diffraction grating, but it has become the common standard for several different applications.

There are several types of diffraction gratings, which can make choosing the right grating for your application a difficult process. This article offers guidance on the various types of diffraction gratings to help outline which is suitable for specific application needs.

Reflection vs Transmission Diffraction Gratings

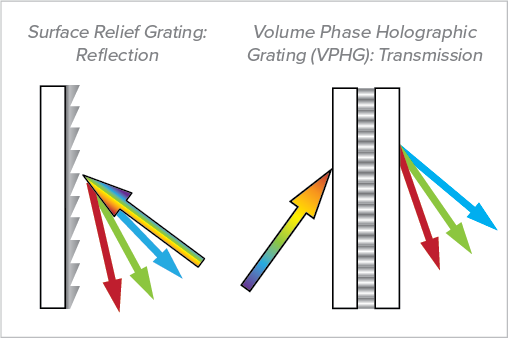

Reflection or transmission is one of the most fundamental distinctions in diffraction grating terminologies. Effectively, a reflection grating diffracts light back into the plane of incidence while transmission gratings transmit dispersed light.

Due to the capacity to offer greater compensation for aberrations, optical systems made with transmission gratings have relatively low alignment sensitivity, which can offer a significant advantage in applications where even minor alignment errors or tiny fluctuations in temperature could significantly impact results. Consequently, transmission gratings are the proffered choice for a number of OEM applications.

Image Credit: Wasatch Photonics, Inc.

Although a key factor, reflection vs. transmission are not the last words in diffraction grating selection.

Diffraction Grating Design Principles

Gratings affect the phase of reflected or transmitted light predicated on their individual structural properties. A traditional surface relief grating is executed by ruling a substrate material with equally-spaced grooves, producing an easily recognizable and popular ‘blazed’ surface.

This can be a time-consuming and costly design process that may necessitate the use of several test gratings manufactured via diamond tooling before fabricating the final component via replication. Ruled gratings are also vulnerable to relatively high levels of light scattering. Once manufactured, a ruled grating must be carefully handled, as it is not possible to clean without a high risk of damage. Dust, fingerprints, or any other contamination amplifies the inherent scatter of the grating over a prolonged period.

Holographic gratings were developed to eradicate most of the errors associated with traditional surface relief components. In short, they are fabricated by exposing a substrate or photoreactive material in a selective manner to the substrate to a laser-generated optical interference pattern of exceptional uniformity. This action then ‘writes’ a periodic structure into the selected medium. Holography is now the manufacturing benchmark for diffraction gratings.

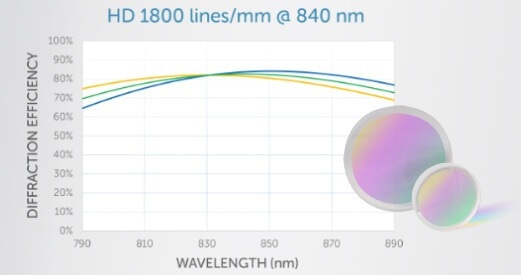

Image Credit: Wasatch Photonics, Inc.

The various types of diffraction gratings can be extended further to incorporate emerging manufacturing techniques for holographic gratings. Etched-in relief gratings made up of fused silica and volume phase holographic (VPH) diffraction gratings, for example, are two drastically different design paradigms for contemporary optical systems. While both deliver considerably greater efficiencies when compared to ruled gratings, VPH grating technology offers the optical engineer a greater range of designs to reach the efficiency profile required.

Selecting a Diffraction Grating

There are a number of key interlinked performance factors to consider when choosing a diffraction grating, including:

- Efficiency: Diffraction grating efficiency is generally expressed as the percentage of incident light broken down into the required order as a function of wavelength, with most traditional gratings yielding asymmetric efficiency curves over the total wavelength range.

- Resolving power: The resolving power of a diffraction grating determines its capacity to split two wavelengths spatially and is primarily determined by the grating’s periodic structure.

- Wavelength range: A diffraction grating’s spectral range relates to the region of electromagnetic radiation that it can disperse effectively, a similar characteristic of the structure.

Choosing Diffraction Gratings with Wasatch Photonics

Throughout the industry, Wasatch Photonics is one of the leading suppliers of precision diffraction gratings for various optical systems. Wasatch appreciates the challenges of selecting the appropriate optics for any given application and is open to designing a grating to a client's specific needs. If you are searching for a new solution, why not contact Wasatch Photonics today to explore the possibilities?

This information has been sourced, reviewed and adapted from materials provided by Wasatch Photonics, Inc.

For more information on this source, please visit Wasatch Photonics, Inc.