In the modern automotive industry, bonding has become a key technology. Today, a car contains approximately 15 - 18 kg of adhesive and runs through dozens of gluing systems during production, according to the Industrieverband Klebstoffe e.V. (adhesives industry association).

More frequently, bonding is becoming a new alternative to screwing, welding, or riveting, and the reasons for this are safety and economy. A high-precision adhesive and sealant application is required in order to guarantee this.

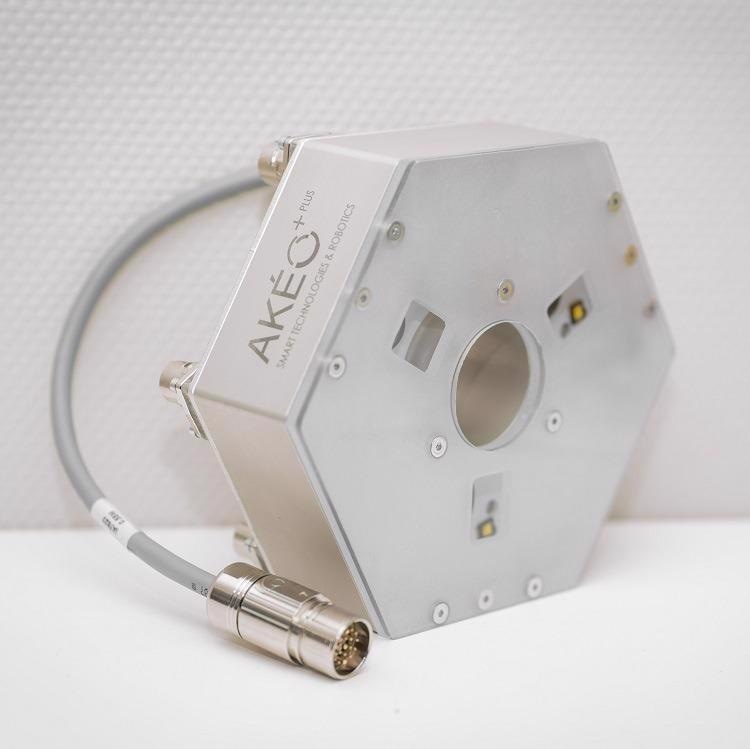

AKEOPLUS, a French company, has developed the AkeoBI sensor, which is able to check adhesive beads in real-time directly on the production line and so ensure 100% quality in material deposition.

Application

Vehicles with a high adhesive content usually perform best in crash tests. This is because, during bonding, the parts to be bonded are not negatively affected. Screws cause holes and welding generates heat, which can influence the materials utilized and their properties.

On the other hand, glue bonds without material changes which is a huge safety factor. Adhesive systems are now employed in both body and engine construction. They fix car windows in the corresponding frames or connect sheet metal securely to each other, ensuring high rigidity of the body.

The former also guarantees a high potential for energy savings. However, a prerequisite for strong connections and sealing is the exact application of the adhesive beads in all bonding processes, particularly with safety-relevant parts. They must be dispensed in the same quality at all locations, even in corners and curves.

Error Minimization and Traceability

Developed by AKEOPLUS, AkeoBI is an intelligent production tool that helps to guarantee 100% quality of material deposition. The sensor inspects all varieties of beads directly on the assembly line in real-time - whether mastic, glue, silicone or foam.

Special algorithms check bead width, position and continuity and detect any lack or surplus of material with an accuracy of +/- 0.5 mm when mounted on adhesive guns on fixed bolts on the assembly line or directly on the robot arm of the bonding system. This is achieved at a speed of 450 mm per second.

AkeoBi - Sensor for quality inspection of adhesive systems. Image Credit: IDS Imaging Development Systems GmbH

AkeoBI can be integrated into almost any production plant due to its low weight of 1.5 kg and its compact dimensions of only 170 mm x 50 mm. In order to meet the requirements of various applications, the system can be configured individually.

For instance, a central unit can perform the inspection with two sensors simultaneously or only trigger random checks.

AKEOPLUS allows the detection of defective material applications by means of a specially programmed powerful software on the basis of previously stored criteria which is clearly visualized for the user on the associated user interface.

After each inspection, a report on each part checked is available immediately. The operator can locate faults straight away and correct them quickly without interrupting production. This ensures traceability, stops any unnecessary downtime and increases production reliability.

Lightweight and compact, AkeoBi can be integrated into almost any production plant. Image Credit: IDS Imaging Development Systems GmbH

3 High-Resolution Cameras with 360° Panoramic View

Three high-resolution industrial cameras supply the images on which the inspection is based and also supply AkeoBI with a 360 ° panoramic view of the components to be inspected.

High-performance LEDs directly in the sensor provide the necessary illumination. The compact GigE uEye LE cameras from IDS Imaging Development Systems that are utilized here are each equipped with a 1.3 megapixel CMOS sensor from e2v.

These GigE board-level cameras also have a range of distinctive features other than their outstanding light sensitivity. For instance, the sensor of the UI-5241LE provides two global and rolling shutter variants which can be switched during operation to allow maximum flexibility for changing environmental conditions and requirements.

A maximum of four Areas of Interest is also available. This permits either several characteristics to be checked at the same time or the AOIs to be captured in an exposure series with different parameters. This means the camera model is particularly suitable for space-critical inspection tasks in quality assurance.

Real-time inspection: Reports are available immediately (OK or NOK). Image Credit: IDS Imaging Development Systems GmbH

The speed of these compact industrial cameras was also ideally suited to the needs of AKEOPLUS. The price-performance ratio, in addition to the IDS software suite with the IDS typical plug and play capabilities, were also key criteria.

The efficient programming interface of the IDS Software Suite enabled us to configure the camera accurately and easily. Indeed we were able to test and define precisely pixel format, image size, frequency and all necessary features in advance. The images are then processed by the camera software. Start, stop, and frequency of acquisition are precisely controlled thanks to the high performance of the IDS camera manager.

Thibaud Cheippe, Developer, AKEOPLUS

Outlook

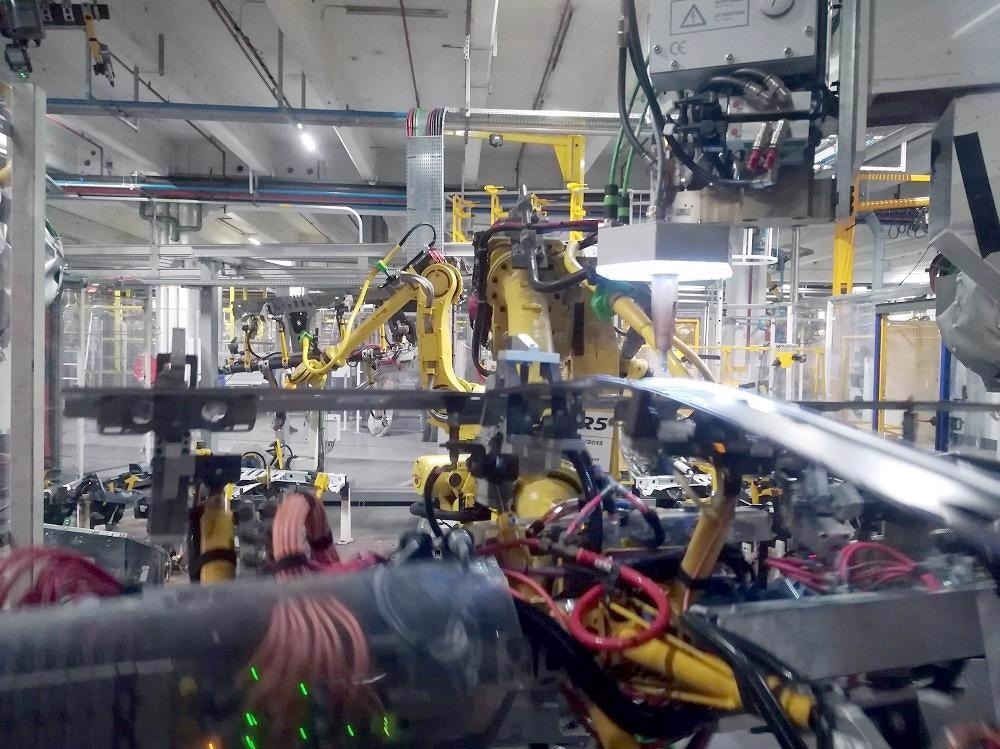

Over 100 AkeoBI sensors are already being utilized around the globe, for example, at the French automobile manufacturer Groupe PSA, which owns the brands Opel, Citroën and Peugeot.

Yet, the combination of high-performance LEDs, high-resolution cameras and matching algorithms supplies companies from a wide range of industries the opportunity to increase the quality of their adhesive bonds and their products and generate real competitive benefits at the same time.

In use, e.g. in the automotive industry. Image Credit: IDS Imaging Development Systems GmbH

In addition to the automotive industry, its suppliers at numerous stages of the aerospace industry and value chain benefit from the efficiency and high level of traceability which is provided by the sensor.

Real-time execution on the production line also ensures a high degree of cost-effectiveness as safety-relevant parts in particular need a 100% inspection. The camera-supported solution from AKEOPLUS ensures safe, contactless connections which provide what they promise.

GigE uEye LE Board-Level Industrial Camera: Compact CMOS Single Board Camera With Excellent Image Quality and Additional Features

- Interface: GigE

- Manufacturer: e2v

- Frame rate: 50.0 fps

- Dimensions: 45.0 mm x 45.0 mm x 26.5 mm

- Weight: 24 g

- Model: UI-5241LE

- Sensor type: CMOS

- Interface connector: GigE RJ45

- Resolution: 1280 x 1024 / 1.31 MPix

- Optical class: 1/1.8"

- Shutter: Global Shutter, Global Start Shutter, Rolling Shutter

- Applications: medical technology, gaze and gesture tracking, 3D scanning, security technology, industrial image processing, traffic monitoring and license plate recognition, quality assurance, astronomy

Image Credit: IDS Imaging Development Systems GmbH

Client

AKEOPLUS has numerous years of experience in various industries, in France and internationally, and combines its competencies in the fields of data, automation and operational efficiency to develop adaptive and scalable assistants for industry 4.0.

Individually tailored technological solutions for the future are created to make digital technology a strong growth driver for its customers.

This information has been sourced, reviewed and adapted from materials provided by IDS Imaging Development Systems GmbH.

For more information on this source, please visit IDS Imaging Development Systems GmbH.