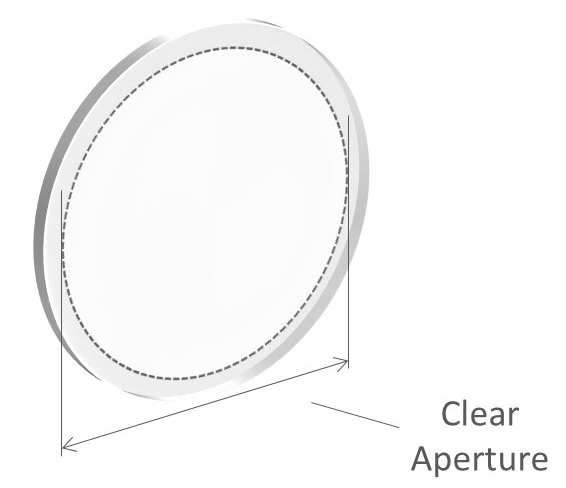

Clear aperture (CA) is defined as the dimensional area of an optical component over which the specifications must be met (Figure 1). The clear aperture is typically specified in diameter for round parts, and in length and width for square and rectangular parts.

Figure 1. Diagram showing the clear aperture (CA) of an optical filter. Image Credit: Alluxa

For optical filters that are situated in an assembly, the clear aperture is controlled by the size of the window on the ring or the housing. In the case of an unmounted filter, clear aperture will depend on whether the parts have been coated to the edge, or if tooling has introduced an uncoated lip around the edge of the part’s coated surface.

In the majority of cases, it is possible to achieve a clear aperture of over 90% for unmounted optical filters. However, this value may necessarily be smaller for large format parts with challenging spectral requirements.

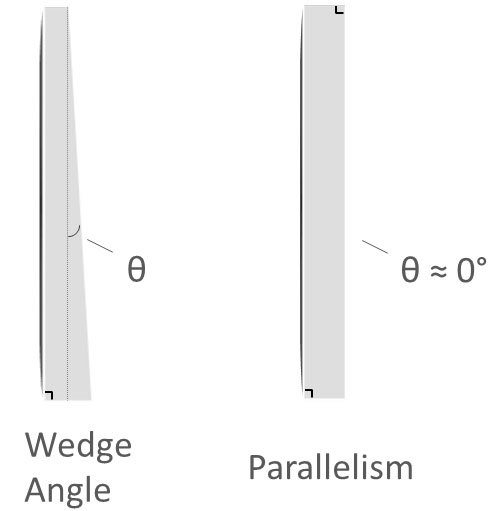

Parallelism and Wedge

The terms parallelism and wedge denote the angle between two surfaces of an optic. Parallelism is specified as the maximum tolerance away from perfectly parallel a single surface can be from a second surface or a reference datum (Figure 2). Parallellism can either be specified as an angle, typically in units of arcminutes or arcseconds, or it can be specified as an envelope tolerance, which is typically noted in millimeters. Conversely, wedge specifications are provided by a particular wedge angle and a ± tolerance, typically noted in units of degrees.

Figure 2. Diagram showing wedge angle and parallelism. Image Credit: Alluxa

It is possible for the manufacturers of optical substrates to achieve precision parallelism or wedge specifications by polishing. Due to the fact that the thin-film coating does not have a marked effect on these particular properties, wedge and parallelism specifications are generally evaluated according to the data from the substrate vendor.

The instrument that is chosen to measure parallelism and wedge specifications will depend on the specification; examples of such instruments include interferometers, autocollimators, goniometers, and coordinate measurement machines.

Alluxa’s Custom Thin-Film Optical Filters

Alluxa’s team of experts has produced key innovations for the optical thin-film field. Along with designing and constructing all of their custom, optical thin-film coating equipment, they invented a new plasma deposition coating process that not only improves the performance of their optical filters, but it also decreases production times.

By utilizing these innovations and pairing them with state-of-the-art automation, proprietary control algorithms, and precision monitoring during the coating process, Alluxa can deliver low-cost, high-performance, custom thin-film optical filters fit for every application.

This information has been sourced, reviewed and adapted from materials provided by Alluxa.

For more information on this source, please visit Alluxa.