Innovative technology allows the simultaneous form measurement of both front and back surfaces of thin optics. Historically, measuring the surfaces of plane-parallel, thin optics has been problematic as the back and front surfaces are so near to each other.

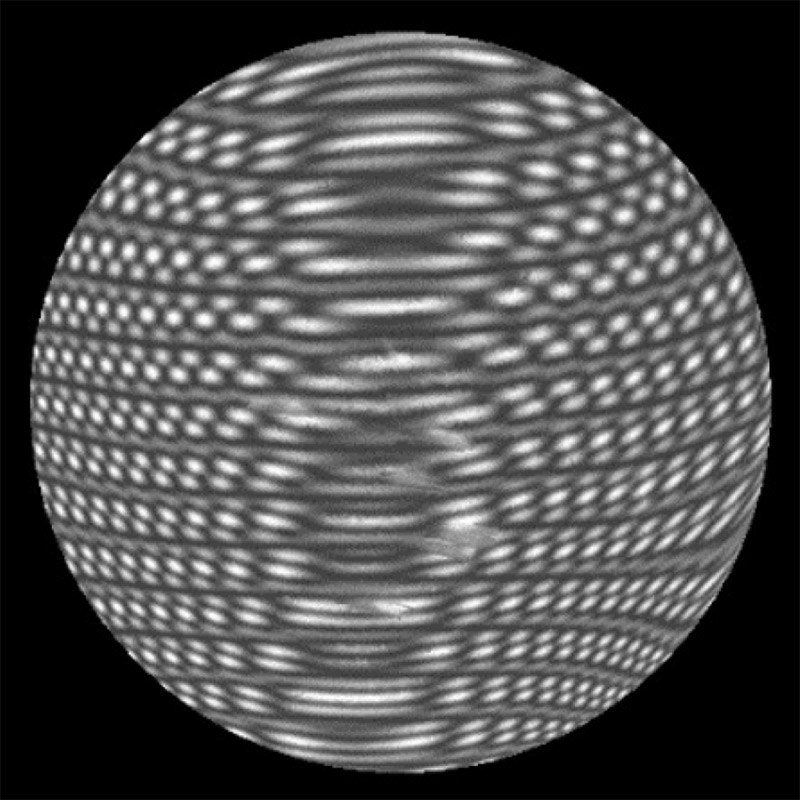

Multiple reflective surfaces in close proximity make it extremely challenging – if not impossible – for standard interferometry methods to acquire reliable measurements.

Image Credit: Zygo Corporation

Why is it Difficult?

When attempting to measure thin optics using traditional phase-shifting interferometry (PSI), a second reflection is returned to the interferometer from the back surface of the optic. This leads to numerous overlapping interference fringes which result in a complex pattern that PSI cannot analyze accurately.

Drawbacks of Traditional Techniques

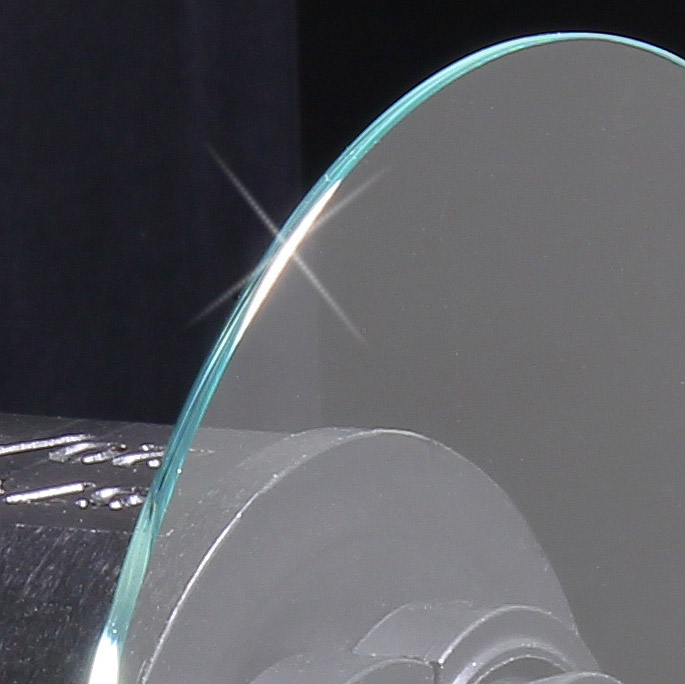

A number of work-around techniques have been developed to combat the fundamental limitations of measuring thin plane-parallel optical components using PSI. For example, coating the back surface with materials that decrease or eliminate the secondary reflection.

Coloring with a dark marker, applying black paint, or spreading petroleum jelly on the back surface adds undesirable steps to the metrology process, takes time, and risks distorting or damaging a thin component when applying or removing the coating.

Image Credit: Zygo Corporation

Only one side of the component can be measured at a time, even when the method of coating the back surface is successful. In addition, since thin components are extremely susceptible to environmental influences, even minute alterations in air turbulence or vibration can affect the measurement data adversely.

The environment could change between measurements if the back and front surfaces are measured separately, and there would be no way to correct it. So, it is extremely beneficial to be able to measure the front and back surfaces of thin optical components simultaneously.

ZYGO Patented Technology Makes It Quick and Easy

Luckily, ZYGO's innovative engineering staff developed (patented) technologies in order to distinguish each surface of a thin plane-parallel optic, and measure the quality of both in one measurement, even for components that are thinner than a millimeter.

Image Credit: Zygo Corporation

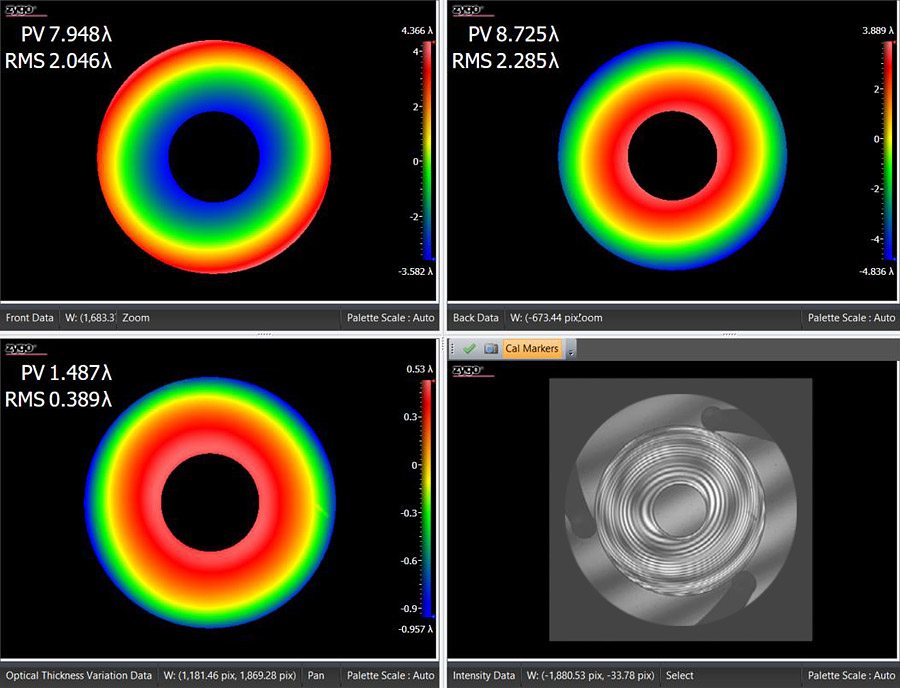

These technologies are key to the capability of ZYGO's Verifire™ MST (multi-surface test) interferometer system, which modulates the laser's wavelength in order to differentiate each surface of the optic being assessed.

Every cavity in the optical path generates a unique interference frequency that defines its cavity length, permitting a clear differentiation and accurate characterization of each surface. Then, in a single measurement, ZYGO's proprietary software algorithms can analyze several wavefronts and characterize the form of each surface independently.

Bonus: Homogeneity and Thickness Variation Measurement

The homogeneity of the refractive index of the material from which it is made is a crucial property of an optical component. Differences in the material's refractive index influence the wavefront passing through it, potentially influencing the performance of the optic in critical applications.

Image Credit: Zygo Corporation

Likewise, differences in the thickness of the optic influence the length of the optical path, which can also affect the wavefront adversely. A standard feature of ZYGO's Verifire™ MST laser interferometer system is the capability to measure optical homogeneity and total thickness variation (TTV).

All it takes is a simple, two-measurement process. Traditional techniques which involve the utilization of oil-on plates, or that require the optic to have a degree of wedge, are no longer needed.

This information has been sourced, reviewed and adapted from materials provided by Zygo Corporation.

For more information on this source, please visit Zygo Corporation.