Image Credit: shutterstock.com/Ambelrip

The use of optical fibres as sensors has garnered major attention in recent years, as they possess many benefits over traditional electronic-based sensors for a wide range of chemical and biological applications.

A team of researchers from Malaysia has now developed a tapered fibre tip optical sensor, that is coated with reduced graphene oxide (rGO), to detect different concentrations of ethanol in water.

The advancements of optical sensors have significantly increased, and this also rings true for those that incorporate graphene.

Graphene-based optical sensors have been used to detect many small molecules and changes in environment, but recent advancements have also seen such devices being miniaturised and providing more efficient response times- making them more of a commercially viable option.

The working mechanism of optical fibres is attributed to the geometry of the fibre itself. Optical fibres are composed of a core, generally made of plastic or glass, surrounded by a cladding material with a differing density and refractive index.

The difference in properties between the two materials allows for light propagation through total internal reflection principles.

The sensitivity of an optical sensor is reliant upon the properties of the cladding material surrounding the fibres, as well as the cladding thickness. The general rule of thumb for an optical fibre is that the thinner the cladding, the higher the sensitivity of the device.

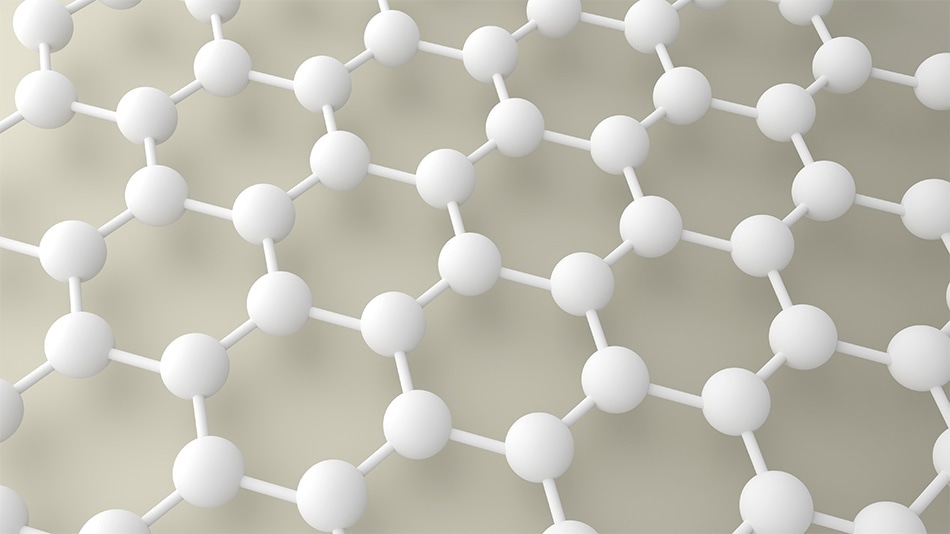

Graphene is an excellent choice of material for enhancing the sensitivity, as it can be present as a monolayer and exhibit an extreme thinness, as well as showcasing excellent optical transparency properties.

Aside from the optical properties, graphene derivatives also exhibit excellent flexibility, robustness, strength and stability, that make them a very attractive material for complex fabrication processes, on both an academic and commercial level.

The Ethanol Sensor

The researchers synthesised the reduced graphene oxide (rGO) sheets through simple thermal, chemical and electrical reduction methods and was used to coat (dropwise) a tapered optical fibre. The device was characterised by X-ray Diffraction (XRD), Raman spectroscopy, and field emission scanning electron microscopy (FESEM).

The researchers varied the thickness of the rGO layers to optimise the device to produce higher sensitivities, with 20-30 nm being the optimum thickness. This was composed of 0.75 mgmol-1 of rGO. Alongside this, the researchers optimised the device in different ethanol concentrations that ranged between 20 and 80 wt% ethanol. 100% ethanol solution was used as a standard.

The sensor provided a dynamic response, and a higher concentration of ethanol in the sensing solution provided a higher reflectance response.

The sensor possesses a high sensitivity and showed a stable response at all concentrations. Even when the sensor tip is removed from the ethanol molecules, the sensor returns to a stable baseline. The response and recovery time of the sensor has been found to be 40 and 70 seconds, respectively.

Overall, the presence of rGO provides an enhanced sensing surface and increased the structural strength of the sensor.

There are many small molecules that can be detected by optical sensors, but the ability to sense ethanol, and provide a direct measurable output based on the exact ethanol concentration, could lend itself to many applications, especially in the food and drink industry where the effective sensing and concentration determination of ethanol can either be a health and safety or a quality control issue.

You can read the entire article here

This information has been sourced, reviewed and adapted from materials provided by SpingerOpen.