Sightline Process Control provides a range of standard or tailor-made 3D/color vision systems that can be installed easily and added quickly to manufacturing facilities. All systems available from Sightline automate measurements like size, color, volume, inclusions, and other crucial QA parameters.

These systems include Sightline’s Product Analysis Software and have been engineered to handle an unlimited number of unique products, where each product configuration can be customized to meet the analysis needs of users.

The standard products can be classified into three major types.

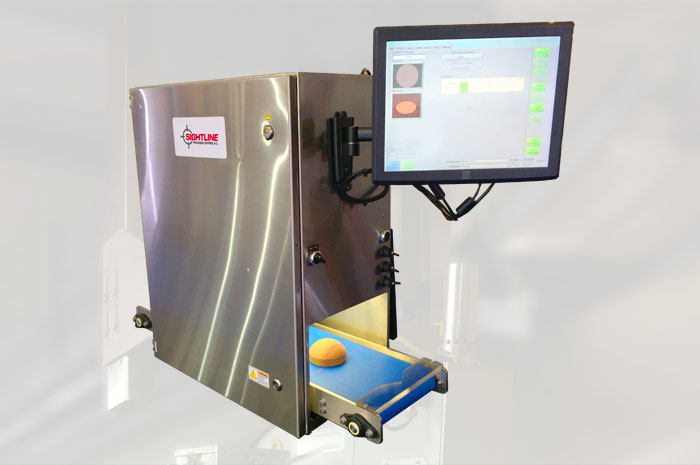

Benchtop Systems

Benchtop systems are small-sized, “plug-and-play” inspection systems that generate over 100 different measurements for each object placed on the integrated conveyor belt.

Image Credit: Sightline Process Control Inc.

Benchtop systems can completely automate manual measurements and quality analysis (QA) processes to enhance accuracy by up to 10x faster than manual measurements. These systems can be configured directly on the plant floor or in the laboratory.

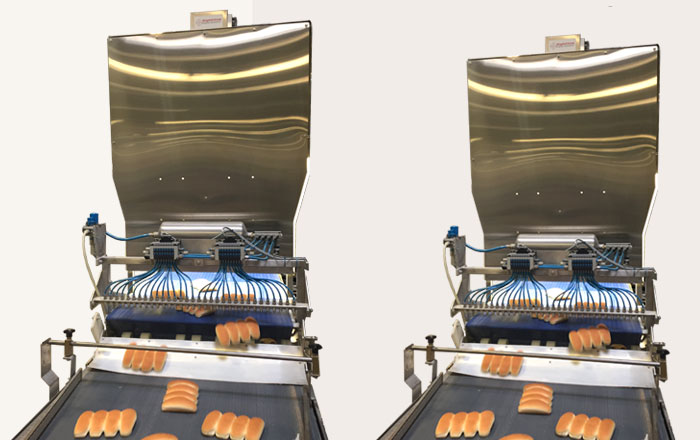

Over-Line Systems

Over-line systems employ a standard, small-sized sensor head directly fitted over an existing customer production line. The sensor head scans all the objects that pass below the system to produce a continuous stream of crucial QA data and production metrics.

Image Credit: Sightline Process Control Inc.

In-Line Systems

In-line systems are “turn-key” units engineered to investigate 100% of all production and come with a built-in variable-speed conveyor and automatic rejection devices.

Image Credit: Sightline Process Control Inc.

The in-line systems can automatically eliminate individual defective objects from the production line, while also measuring and scanning the bottom surface of each object.