Advancements in the field of electron microscopy have led to revolutionary discoveries, particularly in materials science. The electron microscopy of fibers enables experts to examine the morphological layout of fibers and textiles. Scientists perform electron microscopy of fibers not only to examine magnified images of textile specimens but to supplement a diverse and complex field of physical investigation. This article focuses on the utilization of electron microscopy of fibers and textiles for industrial as well as forensic analysis.

Image Credit: Alexander Gatsenko/Shutterstock.com

Basic Operational Principle

In 1932, Ruska and Knoll first discovered the electron microscope's basic operating concept. A glowing filament generates a concentrated electron beam propelled toward the sample. The electrons are dispersed after striking the sample. A detector measures the number of these electrons. For each location on the sample, a pixel in the microscopic image is created, with the intensity of each pixel encoding the number of recorded electrons. Therefore, an electron microscope image is always a grayscale image. Ever since its discovery, the field of electron microscopy of fibers has been constantly evolving. A specialized technique of Environmental Scanning Electron Microscopy (ESEM) along with scanning electron microscopy (SEM) has been used for industrial electron microscopy of fibers and textiles to obtain useful data.

Electron Microscopy of High-Performance Functional Fibers and Textiles

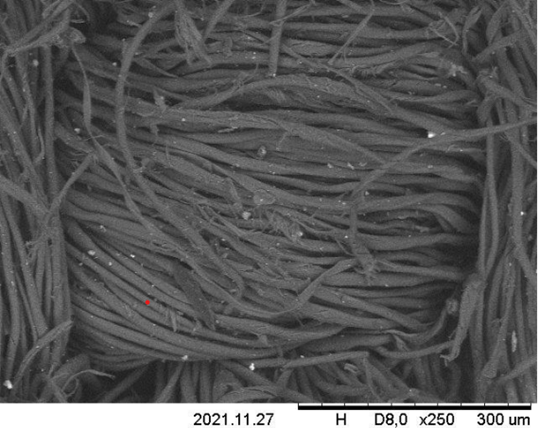

Researchers performed electron microscopy of fibers of multi-functional textile materials using SEM in the latest article published in Textiles. The first material analyzed was commercially available flame-retardant textile cotton fabric. The electron microscopy of fibers revealed the molecular makeup of the cotton fibers in great detail. Furthermore, small, embedded particulates connected to the administered flame-retardant refining agents were identified as a result of electron microscopy of fibers.

Electron Microscopy of commercially available cotton fabric with flame retarding finishing. Study Title: High-Performance and Functional Fiber Materials—A Review of Properties, Scanning Electron Microscopy SEM and Electron Dispersive Spectroscopy EDS Available at https://doi.org/10.3390/textiles2020012

The textile belt manufactured by Kübler Workwear was also analyzed with SEM. The existence of chlorinated modacrylic fibers was determined by electron microscopy of fibers, which indicated an abundance of chlorine. It was evident via the electron microscopy of fibers that the material was composed of blended strands constructed from various fibers. Several filaments displayed a greater contrast, which suggests the existence of a stronger chemical component, such as chlorine.

Challenges of Electron Microscopy of Fibers

Optimizing the electron microscopy of fibers for textile and polymer specimens still requires much research. Deceptive images or inadequate magnification less than the possible theoretical amplification required for electron microscopy of fibers is a major issue. It is a standard aspect of electron microscopy observations that the samples being measured are subjected to an electron beam. It impacts the analyzed sample with energy and contributes electrons. Greater magnification readings have a greater propensity to cause sample injury by energy impact or to exhibit charging effects.

Analysis of Polyester Fabrics Incorporated with Saline-Based Coatings

Polyester fiber textiles are prevalent among consumers due to their longevity, adaptability, and climate resistance. They can be produced in mass quantities at a low price.

A major worry is the absence of breathability, particularly after certain finishing procedures. It does not eliminate moisture from a person's skin, thereby preserving sweating and heat proximal to the skin. Consequently, water-repellent treatment is often necessary for polyester fabrics.

According to new research in the journal Gels, functionally treated polyester samples with five distinct compositions were created for performing electron microscopy of fibers. The most frequently used refining products are fluorine and silicon compounds. Compounds based on fluoroalkyl silane are used to produce films with a high degree of hydrophobicity. Electron microscopy of fibers was performed to examine the surface micro-morphology of a water-repellent textile material. After coating samples with gold, the surface morphology of polyester fabric fibers before and after the application of water-repellent coatings was investigated.

Electron microscopy of fibers revealed that the accumulation of coatings was uniform. Nonetheless, following the alteration, the outer topology becomes heterogeneous. At low magnification, the exterior of the unprocessed polyester fibers was comparatively smooth and the protective film was distributed uniformly. At high magnification, electron microscopy of fibers revealed the presence of numerous nanoscale fissures and projections on the surface of the treated polyester fabric fibers that promote the super-hydrophobic properties of the treated fabrics.

Forensic Electron Microscopy of Fibers and Textiles

Utilizing microscopic traces from single-fiber fragments, forensic laboratories deftly connect individuals, objects, or a crime scene. Occasionally, electron microscopy of fibers can aid in replicating the conditions of an event. In certain instances, such as murder and violence, even the smallest particles can be used as evidence.

Electron microscopy of fibers with energy-dispersive spectroscopy is used to assess elemental fiber components for forensic analysis. A straightforward examination of fiber color under an electron microscope can rule out the possibility that two fibers originate from the same source based on observable pigment variations.

Textile Damage Analysis for Forensic Purposes

The article published in the journal Research and Reports in Forensic Medical Science focuses on the latest advances in the field of forensic textile and fiber damage analysis. Forensic textiles degradation is a subfield of the forensic sciences that analyzes damage done to textiles by electron microscopy of fibers to provide evidence.

The utilization of electron microscopy of fibers enables researchers to estimate firing distances by analyzing the firearm discharge residue surrounding bullet wounds. Estimating the firing distance is a crucial aspect of recreating shootings for forensic analysis.

Electron Microscopy of fibers in a study revealed that the damage to cotton fabrics was comparable at various firing distances. When scrutinizing the synthetic fibers in denim, the authors found molten fibers where polyester was exposed to temperatures above 250°C, resulting in fused fiber ends. Electron microscopy of fibers has transformed the forensic examination of fibers and textiles by providing unparalleled knowledge of their fundamental, elemental, and exterior properties.

In conclusion, the electron microscopy of fibers and textiles has led to the discovery of useful insights and discovery of novel surface attributes. It ensures the research progress for the development of novel materials for improved functionality and enhanced strength.

References and Further Reading

Sfameni S. et. al. (2023). Super-Hydrophobicity of Polyester Fabrics Driven by Functional Sustainable Fluorine-Free Silane-Based Coatings. Gels. 9(2):109. Available at: https://doi.org/10.3390/gels9020109

Mahltig B, Grethe T. (2022). High-Performance and Functional Fiber Materials—A Review of Properties, Scanning Electron Microscopy SEM and Electron Dispersive Spectroscopy EDS. Textiles. 2(2):209-251. Available at: https://doi.org/10.3390/textiles2020012

William, A. (2018). "Forensic textile damage analysis: recent advances." Research and Reports in Forensic Medical Science. 1-8. Available at: https://doi.org/10.2147/RRFMS.S166435

Aditi, G. K. S., & Sharma, S. (2023). Forensic Analysis Of Dyed Textile Fibres With Various Analytical Techniques: An Updated Review. Journal of Pharmaceutical Negative Results, 2812-2823. Available at: https://www.pnrjournal.com/index.php/home/article/view/9120

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.