As technology advances, numerous industries are facing challenges in finding readily available optical components and systems that match the specific needs of their applications.

A wide range of lenses are produced in larger numbers to minimize unit cost. Unfortunately these off-the-shelf lenses often represent a compromise in several aspects of optical performance such as resolution, image format and compactness.

Off-the-shelf lenses used in optical products may also introduce limitations such as shorter product life, unattractive appearance, and a loss of competitive advantage, leading to lower profitability.

Consequently, the demand for custom lens designs tailored to the exact needs of the customer application has dramatically increased.

Resolve Optics Ltd develops OEM quantity special lenses, lens systems, and optical designs for small and large technology businesses. The continued growth of Resolve Optics in what is a highly competitive marketplace has been attributed to a strong track record of pioneering, performance-enhancing optical designs, successful projects, timely manufacture of production quantities of lenses, and meeting target price and quality.

The standard process for OEM lens design and manufacture at Resolve Optics is as follows:

- Customer enquiry

- Enquiry evaluation and discussion of the application

- Initial costed design proposal

- Proposal refinement (if necessary)

- Lens specification agreement

- Purchase order issued by the customer

- Detailed optical and mechanical design

- Review of specifications to confirm the application requirements are met

- Manufacture, assembly, and testing of components

- Lens assemblies delivered to the customer on passing all specification tests

Thanks to a highly experienced team of in-house optical designers, Resolve Optics has established an international reputation for quickly grasping the essential physics behind customer technologies and proposing novel solutions.

High-tech companies are increasingly utilizing this free service offered by Resolve Optics to ensure their products are at the cutting edge of their chosen target applications market.

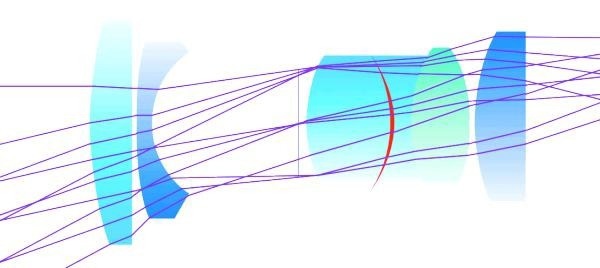

Case Study: Eliminating Compromises in a Camera Design

To enhance the competitive standing and performance of their current generation product, a camera company was required to produce a new lens that would provide very high resolution over a large image format.

Due to the lack of off-the-shelf lenses matching these needs, two catalog lenses were employed as a compromise.

These lenses, rated at f/1.4, collectively covered the field-of-view and image format requirements. However, both had to be stopped down to f/2.6 to achieve the required resolution, downgrading the camera's achievable performance.

Resolve Optics proposed and designed a single 16 mm f/1.4 lens that covers the large image format with 75 cycles/mm resolution down to f/1.4. This new specialist lens matched the camera requirements and was supplied at a price point similar to the two catalog lenses.

Image Credit: Resolve Optics Ltd.

Conclusion

The innovative lens designs from Resolve Optics have allowed customers' high-technology products to reach their full performance potential with extended product lifetimes, access new applications, and achieve a competitive advantage.

Resolve Optics has a proven capability to produce small quantities of high-performance, mounted lens systems rivaling top-of-the-range professional photographic and broadcast TV lenses.

Acknowledgments

Produced from materials originally authored by Mark Pontin from Resolve Optics.

This information has been sourced, reviewed and adapted from materials provided by Resolve Optics Ltd.

For more information on this source, please visit Resolve Optics Ltd.