Visual inspection using a downhole camera and video is an important tool for drillers and borehole maintenance engineers. Such inspection systems are crucial to determining the condition of a well or borehole as well as the nature and extent of any problems.

Using this technology to complete surveys before and after treatment is an important part of any maintenance program, as they enable operators to comprehend the specific areas in a well that could need attention, as well as verify the effectiveness of the treatment. Inspection surveys also offer a valuable marker in the history of the well and its rehabilitation.

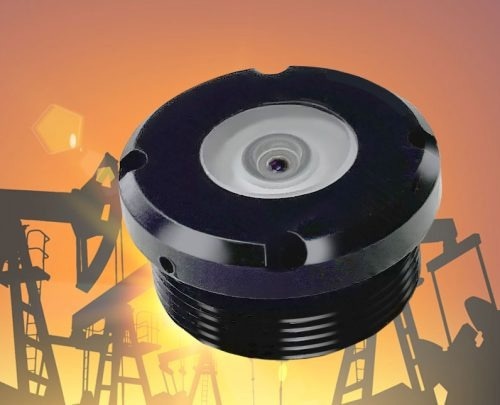

Image Credit: Resolve Optics Ltd.

Resolve Optics Ltd. recently delivered the initial batch of M12 fisheye lenses to a frontrunning visual analytics company for their new array camera optimized for borehole inspection applications. These custom-designed specialist lenses expand the capabilities of the array camera to offer a continuous 360° sightline of the wellbore’s internal diameter.

The sturdy lens was optimized to provide a large (186⁰) field-of-view, superior short-distance imaging clarity, and optical correction for the pipe curvature.

The clients’ cameras included a range of four pre-aligned, high-definition video devices combined with four application-optimized fisheye imaging lenses. This uniquely allows for vivid, 360° dynamic maps of the well state and behavior of the lubricator to the toe of the well in one continuous run-in hole.

The specialized design of the array camera takes four high-definition, high frame-rate video feeds and stitches them together for an infinitely long, continuous well image, greatly reducing the data acquisition time and improving the mechanical reliability of the system.

This information has been sourced, reviewed and adapted from materials provided by Resolve Optics Ltd.

For more information on this source, please visit Resolve Optics Ltd.