Sponsored by CavitarReviewed by Louis CastelDec 13 2022

Industrial manufacturing employs a wide variety of image sensors to produce high-quality goods and effective manufacturing techniques. Due to their inherent ability to create 2D- or even 3D-information, camera-based sensors frequently offer many advantages over other types of sensors.

The selection of illumination is essential for obtaining the desired information from the procedure. Despite being the most popular light source for machine vision systems, LEDs cannot meet a number of specific requirements.

The limitations of conventional light sources like LEDs or halogen lamps are addressed by CAVILUX laser illumination. Due to their capacity to eliminate motion blur and see-through thermal radiation, these lasers are made to be simple to integrate into machine vision systems. This gives machine vision systems new capabilities.

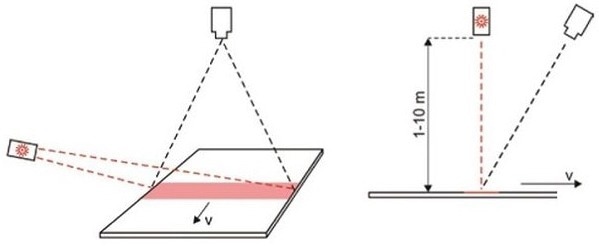

Image Credit: Cavitar

Direct Light

- Accurate and powerful lighting, even at distances of at least 10 meters (light source can be high above or to the side from the disturbances of the production line)

- Different lighting arrangements and lighted areas depending on the requirement of the application

- Fiber coupling provides variability

- Combined direct and structured light for simultaneous topography measurement and area imaging

- E.g., topography, distant illumination

- For industrial applications of area scan cameras

- Recommended product: CAVILUX OEM

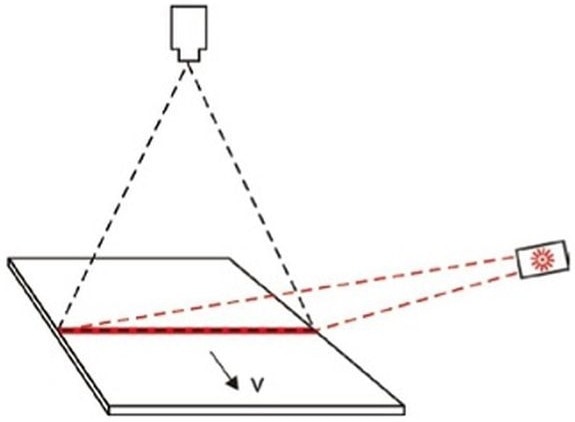

Image Credit: Cavitar

Line Light

- Creation of high-intensity line profiles that are safely spaced from manufacturing line disturbances

- Line lengths up to several meters

- Light intensity is quite consistent throughout the illuminated region. Separate line widths beginning at 1 mm

- E.g., flow measurements, web inspection—surface and density (paper, wood, glass, foil etc), geometrical measurements of long targets

- Applications in the paper industry and hot metal industry

- Recommended product: CAVILUX OEM

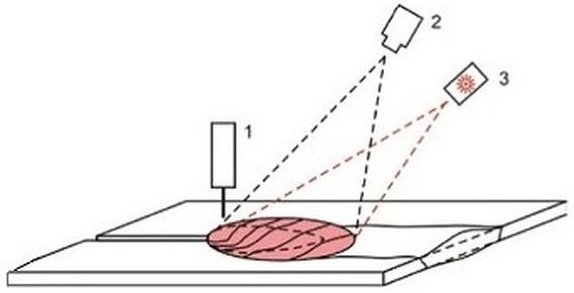

Image Credit: Cavitar

Structured Light

- Laser triangulation is combined with the CAVILUX laser’s outstanding feature of seeing through heat

- With just one light source, several patterns can be produced

- A uniform light that has dark patterns on it (combines image and e.g., multiple lines)

- High resolution and contrast between dark and illuminated regions

- Recommended product: CAVILUX OEM

- E.g., surface reconstruction, profile measurement in welding monitoring, long targets

This information has been sourced, reviewed and adapted from materials provided by Cavitar.

For more information on this source, please visit Cavitar.