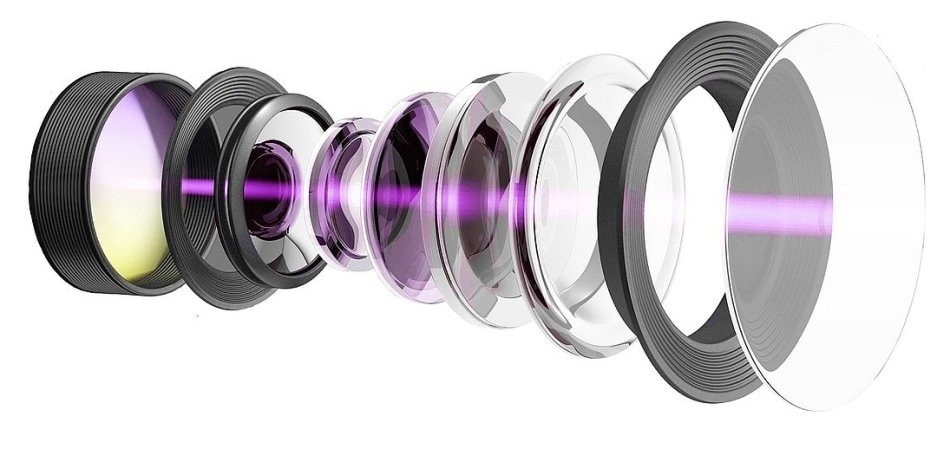

Often challenging, time-consuming processes, optical alignment and micro-optic positioning requires new solutions. The difference between success and failure can come down to just the smallest of positional variations in photonic and optical manufacturing. Misalignments on the nanoscale between the elements or inputs and outputs of an optical or photonic assembly can have a consequential impact on its performance. This issue spreads through a wide-range of advanced opto-electronic manufacturing markets, from lenses in high-performance cameras and objectives, to LIDAR assemblies, lasers, and silicon photonic wafers in semiconductor manufacturing processes.

F-712.PM1 High bandwidth optical power meter.

One such technology that improves the performance is known as ‘active alignment’, it also has a positive impact on profitability and yield in the manufacturing of photonics components and advanced optics for the modern technological era. Traditionally, specific elements within an optical system are serially aligned through a sequence of time-consuming loops. This method was to ensure the alignment reached its peak capability across multiple degrees of freedom and that dependencies between elements were accounted for.

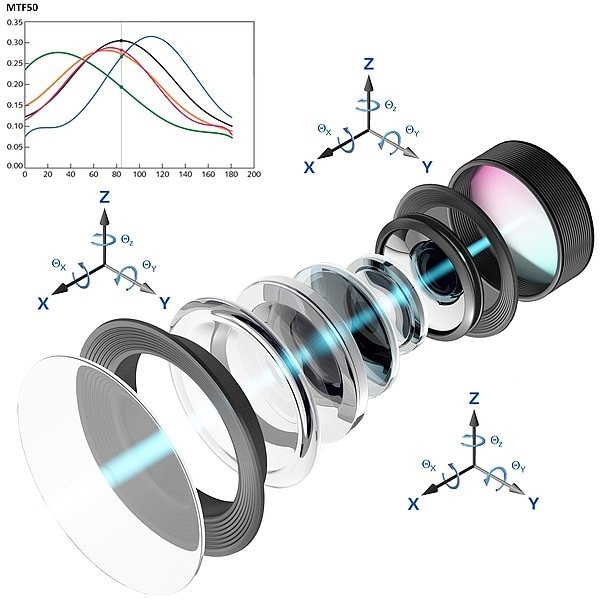

Alignment of multiple lens elements is a complex task now enhanced up by PI's unique algorithms, inserted directly into the controller firmware, along with unique mechanical alignment units, enables parallel alignment of multiple lenses in a single operation.

The history of innovation in optical alignment is a colorful one, but in-spite of this fact, multi-channel active alignment is the first ‘real’ progression in terms of manufacturing technology for thirty-years. That is not to say numerous advancements in the field haven’t been made, but each of these has abided by the same basic principles: an alignment of one element or DOF is performed, then a small improvement in another element or DOF is attempted, requiring a re-optimization of the first item.

Repeating this loop often dozens or hundreds of times is particularly time-consuming and an often costly process. PI’s Fast Multi-channel Photonic Alignment technology bypasses this legacy approach by making use of intelligent parallel alignment algorithms within the firmware of the motion controllers. When initiated, these algorithms simultaneously execute precise and frequent motions on the nanoscale to measure the input of each element’s misalignment in parallel to each DOF. The controllers autonomously adapt to each of the elements until they achieve optimal positioning and orientation. Thus, the time-consuming loop of yesterday can be replaced with one-step parallel optimization.

There are a wide-scope of benefits to multi-channel optical active alignment.

XYZ Gantry System & Hexapod Robot—Active Alignment of Photonic Array—Industrial Packaging Automation

Combination of high-performance gantry system with dual hexapod for fast active fiber array alignment.

Rapid & Reliable Positioning

The benefit of advanced multi-channel active alignment is that it is able to synchronize in order to conduct parallel or simultaneous adjustments of multiple elements in multiple DOFs. Autonomous adjustments are made via a series of distinctive control algorithms in the controller firmware which communicate with metrological and positional equipment to affect to each element simultaneously. During a single operation, the key position of each element is determined to ensure a global optimization for the very best overall performance. The subsequent increase in speed for optical manufacturing is outstanding.

Cost-Effective and Space Saving

Parallelism in alignment is not only having a great and positive impact on speed but also reducing costs and real estate needed to run a manufacturing operation. With optical devices becoming increasingly complex in the development and roll-out of each new generation, consumers are still eager to see reduced costs. The speed and precision of parallel active alignment technology could mean that a reduction of operating costs without compromising device quality is a very real possibility. It has a key role in advanced silicon photonics test and manufacturing processes and can now be utilized in optical assembly and laser manufacturing.

Ultra-Precision Alignment

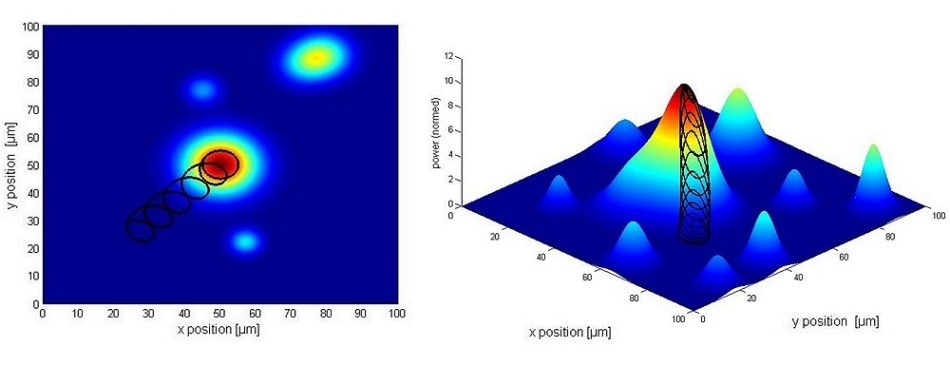

The optimization of signal peaks within a single second is permitted by the exploratory motions of a multi-channel active alignment system which can be programmed for micro- and nanoscale adjustments, with integrated parallel gradient search technology enabling. The advantages of the system come when faced with complex alignment situations, e.g. with arrays or multiple sequential components where interdependencies can affect overall signal degradation even when one path or component seems otherwise perfectly aligned.

Gradient search routine and optical power distribution.

Higher Yield Manufacturing

A key target area for manufacturers is automated assembly, which they hope to utilize to improve returns on investment (ROIs) by bringing down the cost of operations and increasing manufacturing yields. Thus, using parallel, active alignment technology, boosting complex multiple optical elements can typically be consolidated into a single step. Trial-and-error or looping sequences can be disregarded when trying to improve the performance which was the case in legacy systems. This ensures the desired cost reductions and quality improvements are met by doing away with wasted time and compromises in performance.

The cost-effectiveness is self-evident. The higher the yield increase of the manufacturing process is determined by the more complex the optical elements to be aligned.

Active Alignment with PI

PI is a world leader in optical active alignment technology, offering breakthrough Fast, Multi-Channel Photonics Alignment (FMPA) technology across a wide range of applications. PI has recognized the potential for active alignment beyond the photonics sector and have already registered the commercial benefits of this pioneering technology for smartphone cameras, optical cables, laser manufacturing, and much more.

Learn more about how active alignment technology speeds up manufacturing of optical systems.

This information has been sourced, reviewed and adapted from materials provided by PI (Physik Instrumente) LP.

For more information on this source, please visit PI (Physik Instrumente) LP.