Whether it’s right under our nose or far away, when we observe an object we see it - provided we have healthy eyes and normal vision or suitable glasses - in focus. For this to work, muscles deform the lenses of our eyes and adjust them to a suitable focal distance.

For miniaturized technical devices, microscale lenses with a similar adaptable focus could be an advantage. In the journal Angewandte Chemie, Hong-Bo Sun and a team from Jilin University (China) have described a new approach to the production of adjustable microlenses made from protein gels.

Proteins are potentially useful as “building materials” for microcomponents because they are readily available, inexpensive, and biocompatible. They can also change their properties in response to external stimuli, which makes them an interesting material for use in adjustable microlenses. However, lenses must be extremely precise in order to meet optical requirements - something difficult to achieve with proteins. In addition, they must be fast, simple, and inexpensive to produce.

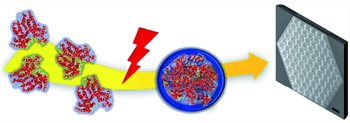

The Chinese researchers have now met this challenge: They used a laser to “write” the desired micrometer-sized lens shape out of a solution of bovine serum albumin, a protein. Methylene blue acts as a photosensitizer, which captures the light energy like an antenna and triggers a crosslinking reaction of the protein molecules. Driven by a computer, the laser cuts out the desired three-dimensional form voxel by voxel. A voxel is a three-dimensional pixel, a tiny segment of volume. The irradiation used is in femtosecond pulses, which lasts on the order of 10-13 seconds. The crosslinking reaction only takes place in the locations that are irradiated. After the reaction, the protein molecules that have not reacted can simply be rinsed away. What stays behind is a cross-linked, aqueous protein gel in the shapes of micrometer-sized lenses.

Direct writing with lasers usually results in structures that have too rough a surface for optical applications. By optimizing the duration of the laser pulse, the pulse intensity, and the protein concentration, Sun and his team obtained lenses with outstanding optical properties.

The special trick in this case is that the amount of liquid absorbed by the protein gel depends on the pH value of the solution. Increasing the pH causes the lens to swell. If the increase in thickness is limited by a glass surface, the lens primarily grows in width and becomes flatter. If the pH value is reduced, the gel shrinks and the lens is more curved. Because the radius of curvature determines the focal length of the lens, this method can be used to focus the microlenses.

Because the protein lenses are biocompatible, they may be used in optical analytical systems for medical diagnostics or lab-on-a-chip technology.